Nylon plastic material for automobile electroplating as well as preparation method thereof

A technology for nylon plastics and automobiles, applied in the field of automobile plastics, can solve problems such as unsatisfactory electroplating performance of nylon, and achieve the effects of improving etching effect, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

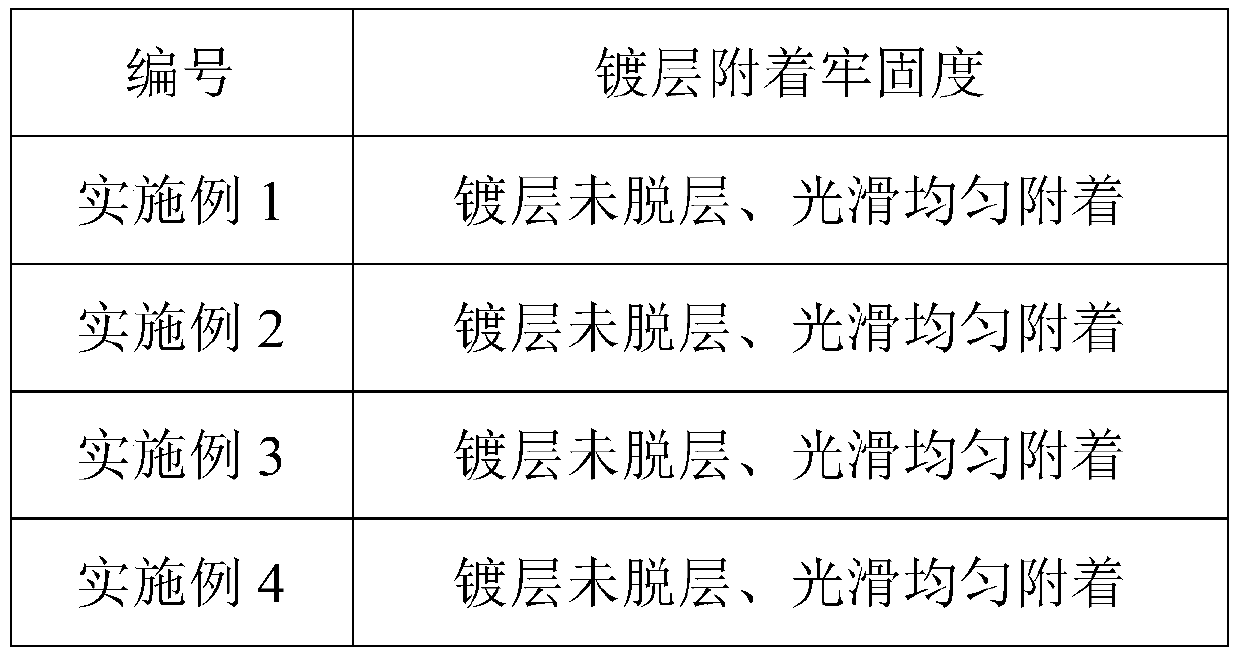

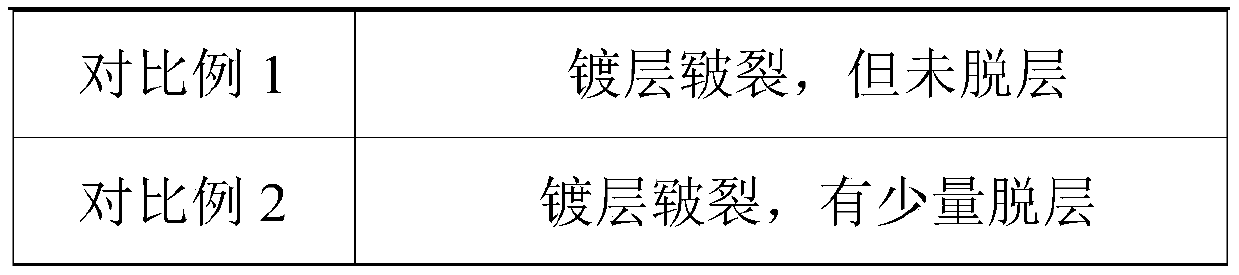

Examples

Embodiment 1

[0035] Adopt the following method to prepare a kind of nylon plastic material for automobile electroplating, specifically include the following steps:

[0036] a. Preparation of modified silica microspheres: uniformly disperse silica microspheres and silane coupling agent A151 at a weight ratio of 15:1, heat up to 65°C and stir for 1 hour to obtain modified silica microspheres, spare.

[0037] b. Preparation of porous aluminum hydroxide-coated silica microspheres: use sodium aluminate as the aluminum source, ammonium acetate as the pore-forming agent, mix the aluminum source, pore-forming agent and water into a solution, and pour it into a hydrothermal In the reaction kettle, add modified silica microspheres, disperse evenly, raise the temperature to 75°C and maintain the temperature for 8 hours, filter, wash repeatedly with water and ethanol, and dry at 100°C for 10 minutes to obtain porous aluminum hydroxide Coated silica microspheres; the weight ratio of aluminum source, p...

Embodiment 2

[0040] Adopt the following method to prepare a kind of nylon plastic material for automobile electroplating, specifically include the following steps:

[0041] a. Preparation of modified silica microspheres: uniformly disperse silica microspheres and silane coupling agent A151 at a weight ratio of 15:1, heat up to 65°C and stir for 1 hour to obtain modified silica microspheres, spare.

[0042] b. Preparation of porous aluminum hydroxide-coated silica microspheres: use sodium aluminate as the aluminum source, ammonium bicarbonate as the pore-forming agent, mix the aluminum source, pore-forming agent and water into a solution, and pour it into the water Add modified silica microspheres to the thermal reaction kettle, disperse evenly, raise the temperature to 90°C and maintain the temperature for 3 hours, filter, wash with water and ethanol repeatedly, and blow dry at 100°C for 30 minutes to obtain porous hydroxide Aluminum-coated silica microspheres; the weight ratio of aluminu...

Embodiment 3

[0045] Adopt the following method to prepare a kind of nylon plastic material for automobile electroplating, specifically include the following steps:

[0046] a. Preparation of modified silica microspheres: uniformly disperse silica microspheres and silane coupling agent A151 at a weight ratio of 15:1, heat up to 65°C and stir for 1 hour to obtain modified silica microspheres, spare.

[0047] b. Preparation of porous aluminum hydroxide-coated silica microspheres: using sodium aluminate as the aluminum source, ammonium acetate and ammonium bicarbonate as the pore-forming agent, mixing the aluminum source, the pore-forming agent and water into a solution, pouring Put it into a hydrothermal reaction kettle, then add modified silica microspheres, disperse evenly, raise the temperature to 80°C and maintain the temperature for 5h, filter, wash repeatedly with water and ethanol, and blow dry at 100°C for 20min to obtain Porous aluminum hydroxide coated silica microspheres; the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com