Sludge drying machine capable of carrying out combined adjustment on internal structure according to sludge properties

An internal structure, sludge drying technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of stability and applicability of drying equipment, and achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

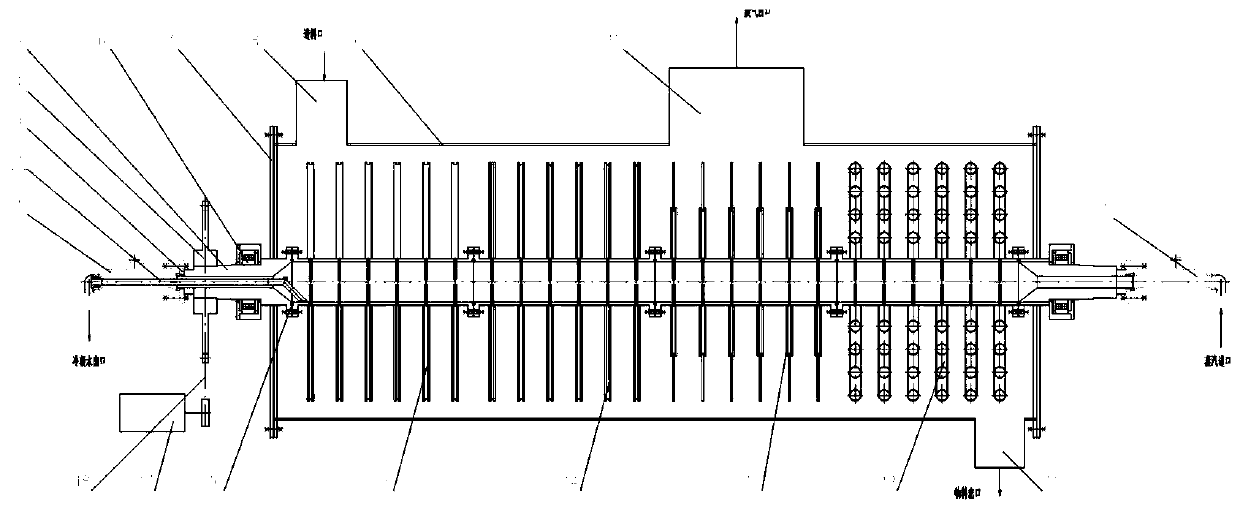

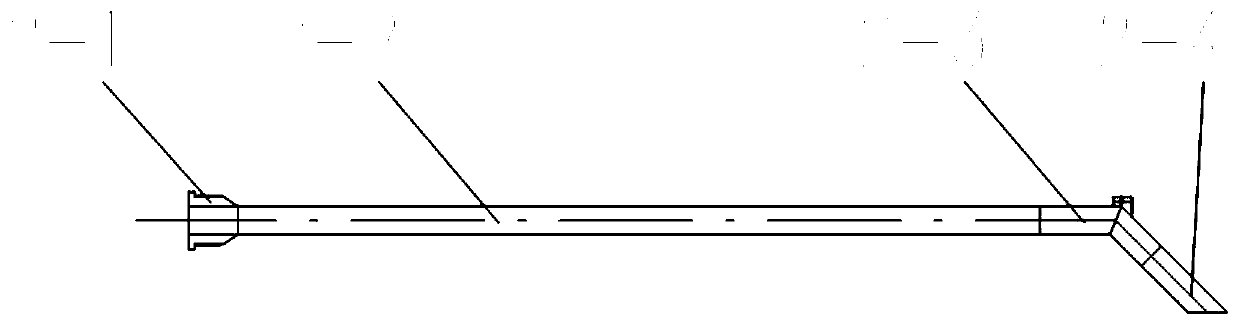

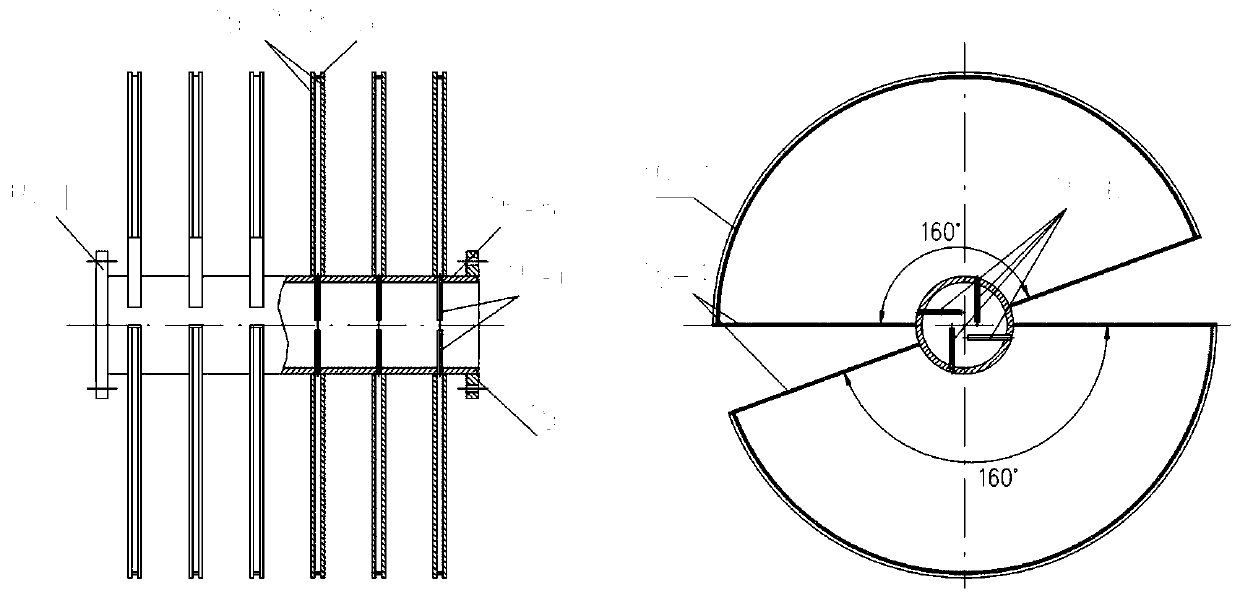

[0024] like Figure 1-6 As shown, a sludge drying machine that can adjust the internal structure according to the properties of the sludge, including a shell 9, a sprocket 5 fixed on the heating spindle that can transmit the torque of the driving device, and a supporting heating The main shaft and its free-rotating bearing and bearing seat assembly 6, the end caps 7 fixed on both sides of the housing, the driving device 17, the transmission chain 18 and the heating main shaft; the shaft head 4 at both ends of the heating main shaft adopts a loose sleeve flange 3 Connect the swivel joint 1, and the swivel joint 1 is provided with a drainage core pipe 2. The heating spindle includes the first spindle heating body type 12, the second spindle heating body type 13, the third spindle heating body type 14, and the fourth spindle heating body type 15. The different types of spindle heating bodies are connected by flanges. A sealing gasket 16 is provided between the flanges to prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com