Adsorbent for normal-temperature removing of dibenzyl disulfide in transformer oil and method

A technology of dibenzyl disulfide and transformer oil, applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problem of agglomeration of active sites on the surface of adsorbents, lack of homogeneous mixing steps, complex preparation process, etc. problems, to achieve the effect of improving adsorption selectivity, reducing energy consumption, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

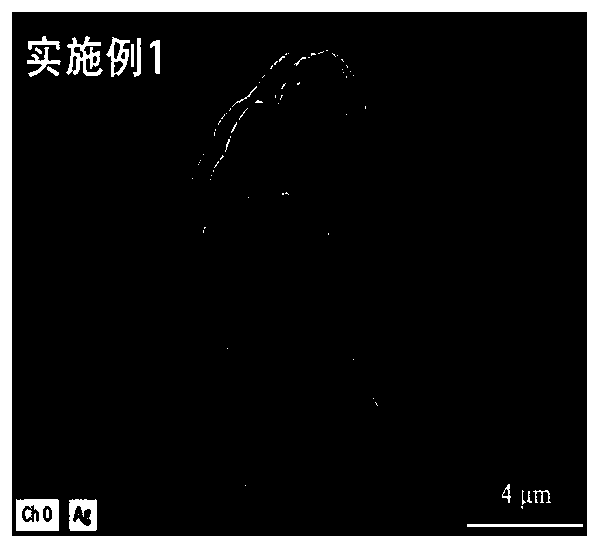

Embodiment 1

[0040] (1) Dissolve 1 g of silver nitrate in 10 g of deionized water, add 10 g of kaolin with a mesh number of 80 mesh, and ultrasonically disperse the kaolin for 20 minutes;

[0041] (2) Put the raw materials in a planetary mixer, first perform synchronous high-speed rotation and revolution stirring under normal pressure, the rotation speed is 1000rpm, the revolution speed is 800rpm, the stirring time is 1h, and then the internal pressure of the stirring chamber is set to 100Pa, low-speed synchronous rotation and revolution stirring, wherein the rotation speed is 100rpm, the revolution speed is 60rpm, and the stirring time is 20min.

[0042] (3) The prepared slurry was dried at a temperature of 150° C. for 12 hours, and a block sample was obtained after drying.

[0043] (4) Grinding the bulk sample, passing through a 120-mesh sieve after grinding, and finally preparing an adsorbent with uniform particles.

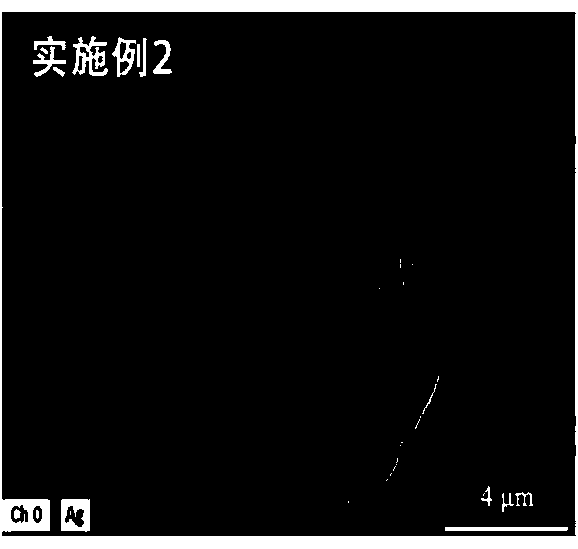

Embodiment 2

[0045] (1) Dissolve 1 g of silver nitrate in 15 g of deionized water, add 20 g of pseudo-boehmite with a mesh number of 90, and ultrasonically disperse the pseudo-boehmite for 20 minutes;

[0046](2) Put the raw materials in a planetary mixer, first carry out synchronous high-speed rotation and revolution stirring under normal pressure conditions, the rotation speed is 1100rpm, the revolution speed is 900rpm, the stirring time is 1.2h, and then the internal pressure of the mixing chamber is set 150Pa, low-speed synchronous rotation and revolution stirring, wherein the rotation speed is 150rpm, the revolution speed is 80rpm, and the stirring time is 30min.

[0047] (3) The prepared slurry was dried at a temperature of 120° C. for 14 hours, and a block sample was obtained after drying.

[0048] (4) Grinding the bulk sample, passing through a 140-mesh sieve after grinding, and finally preparing an adsorbent with uniform particles.

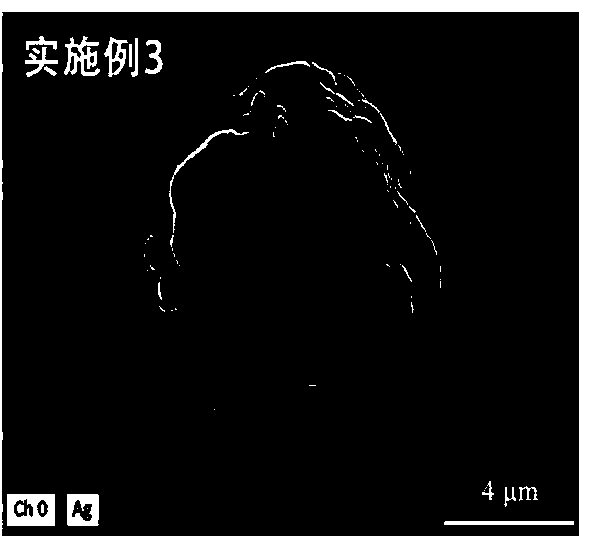

Embodiment 3

[0050] (1) Dissolve 1 g of silver nitrate in 20 g of deionized water, add 30 g of sepiolite with a mesh number of 90, and ultrasonically disperse the sepiolite for 30 minutes;

[0051] (2) Put the raw materials in a planetary mixer, first carry out synchronous high-speed rotation and revolution stirring under normal pressure conditions, the rotation speed is 1200rpm, the revolution speed is 1000rpm, the stirring time is 1.5h, and then the internal pressure of the mixing chamber is set 200Pa, low-speed synchronous rotation and revolution stirring, wherein the rotation speed is 200rpm, the revolution speed is 100rpm, and the stirring time is 40min.

[0052] (3) The prepared slurry was dried at a temperature of 180° C. for 16 hours, and a block sample was obtained after drying.

[0053] (4) Grinding the bulk sample, passing through a 160-mesh sieve after grinding, and finally preparing an adsorbent with uniform particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com