Constant-temperature and multi-stage waste gas treatment system

A waste gas treatment, multi-stage technology, applied in the fields of environmental protection, biology, waste gas, petrochemical, adsorption, washing, can solve the problems of poor treatment effect of waste treatment system and inability to work normally in low temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

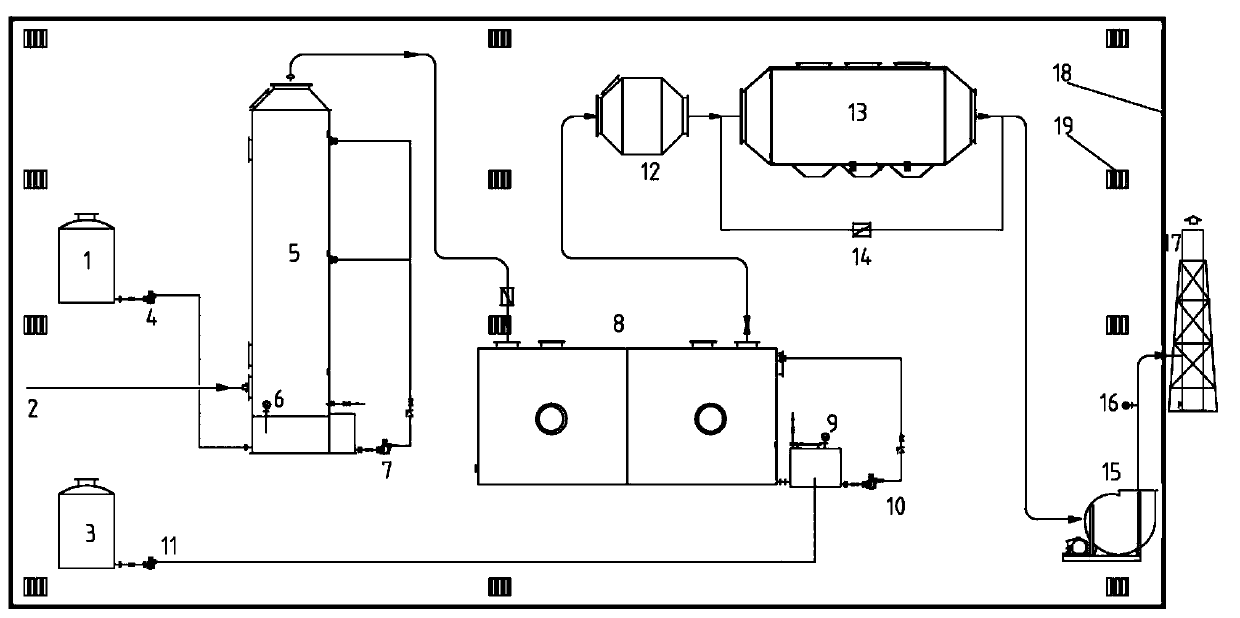

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0024] Such as figure 1 As shown: this embodiment discloses a constant temperature, multi-stage exhaust gas treatment system: including a greenhouse 18 and a raw gas pipeline 2 connected in sequence in the greenhouse 18, a washing tower 5, a biological box 8, and a gas-liquid separation tank 12, The warm room 18 is also provided with a centrifugal fan 15 and several heaters 19. The centrifugal fan 15 is used to drive the gas to be processed to circulate in the system. The activated carbon adsorption box 13 is connected to the outside air. The lye circulation pump 7 of lye circulation.

[0025] In order to improve the effect of biological decomposition, the biological box 8 of this embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com