Torsion spring life testing device

A technology for life testing and torsion springs, which is applied in the field of torsion spring life testing devices, can solve the problems of torsion spring size limitation, rotation angle limitation, and failure to meet test requirements, etc., and achieve high efficiency, wide application range, and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples given are not intended to limit the present invention.

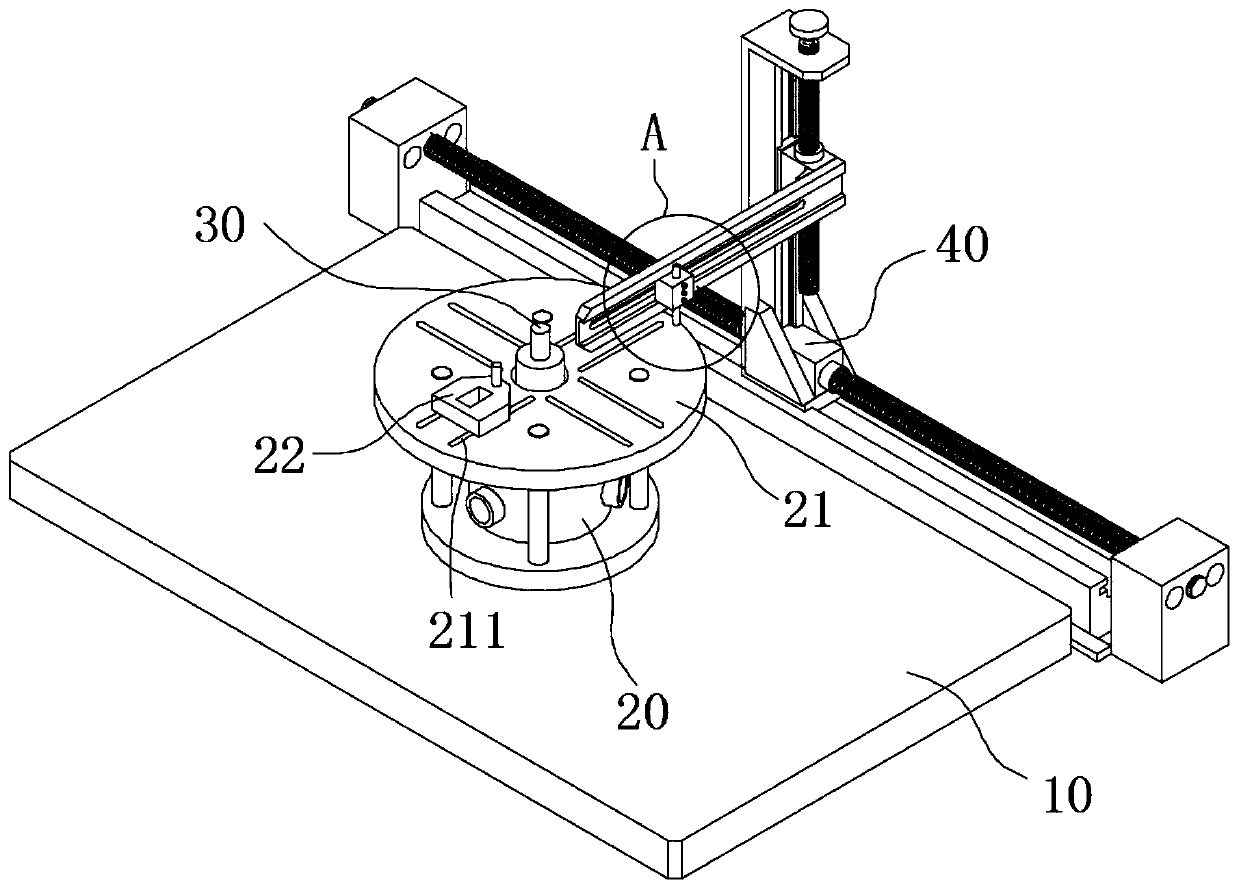

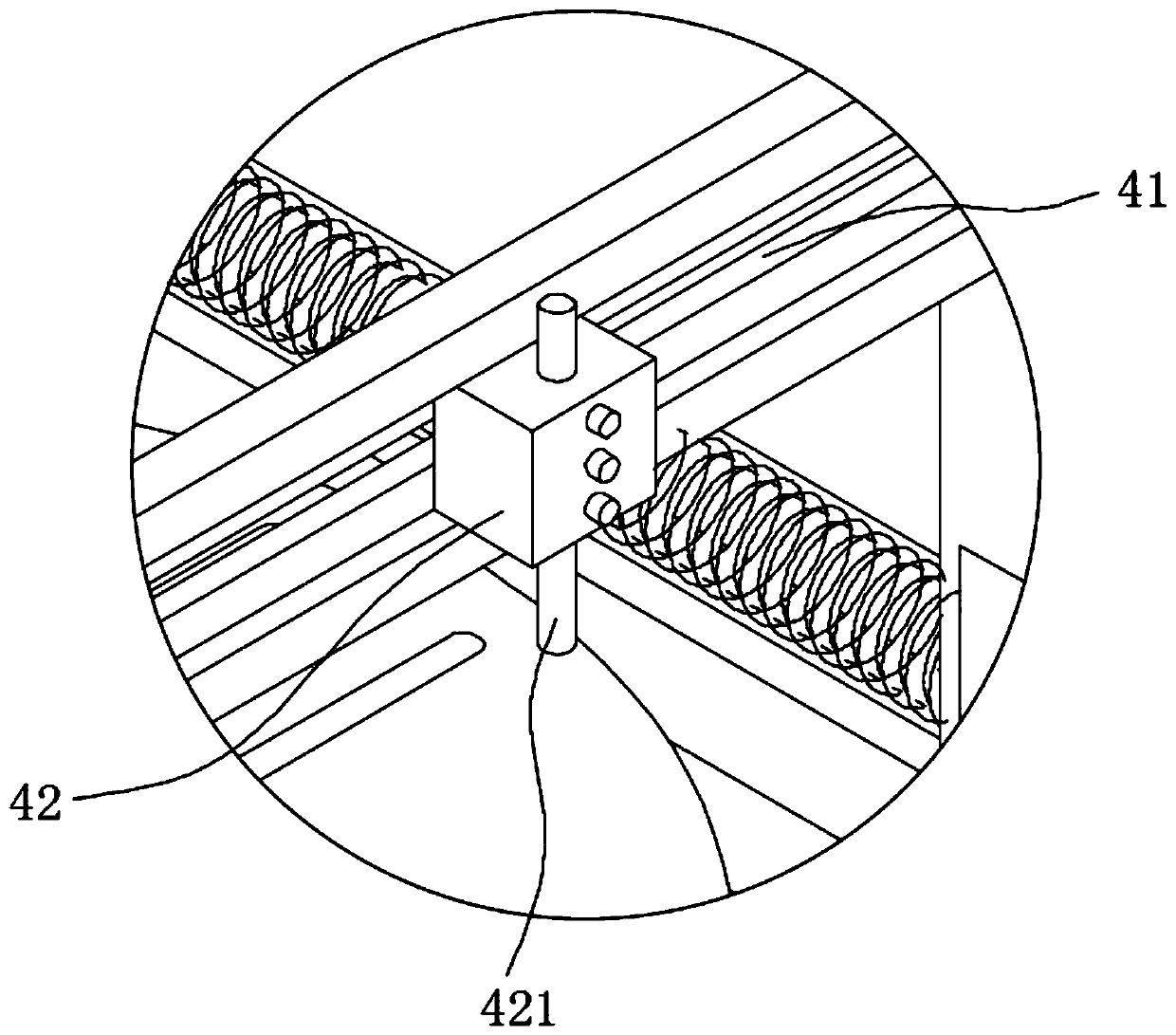

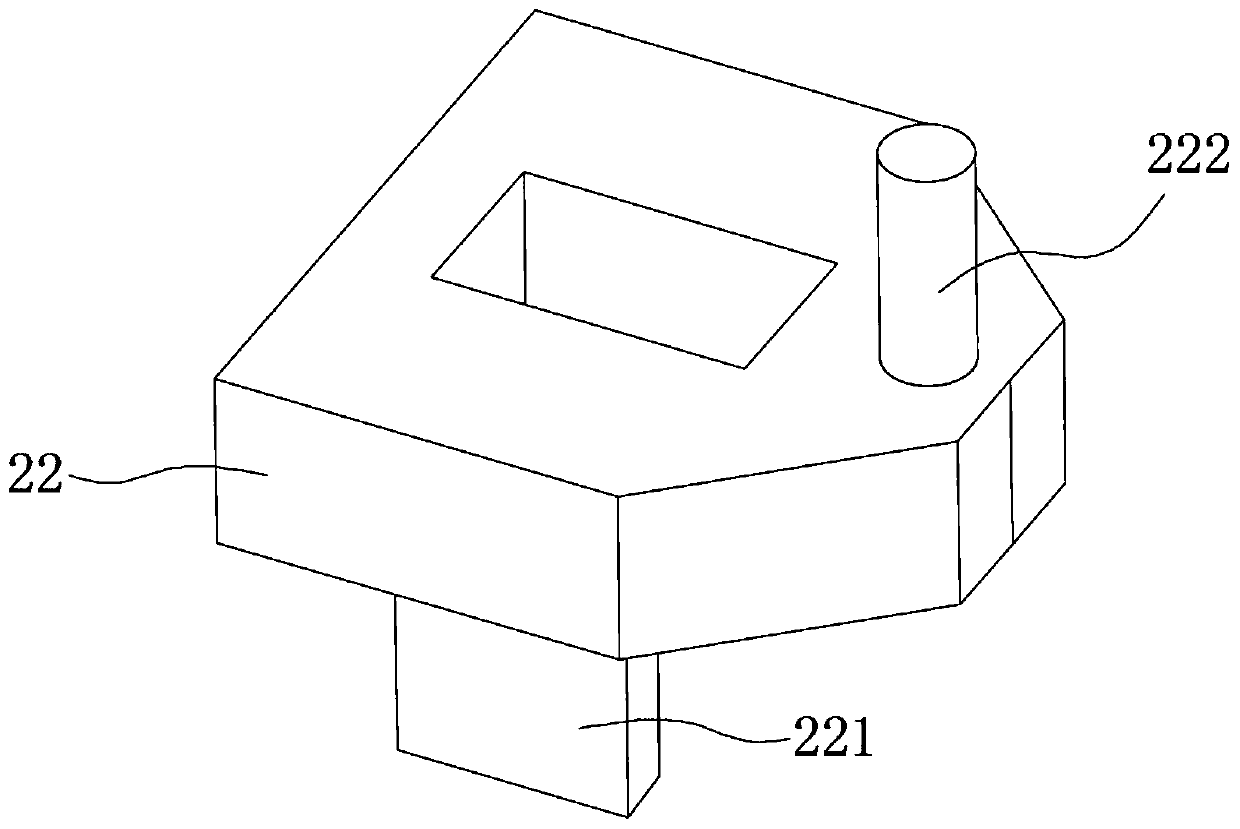

[0024] Reference Figure 1-Figure 4 As shown, the present invention discloses a torsion spring life testing device, including a base 10, a fixed shaft 30 is fixedly arranged on the base 10, a torsion spring to be tested is sleeved on the fixed shaft 30, and a fixed side of the base 10 The assembly fixes one torsion arm of the torsion spring to be tested, and the other torsion arm of the torsion spring to be tested is fixedly arranged on the first positioning block 22. A rotating assembly is provided on the base 10. The rotating assembly includes a drive source 20 and a turntable 21. The drive source 20 drives the turntable 21 to rotate. The first positioning block 22 is fixed on the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com