A Tunnel Support System Applicable to Weak and Broken Surrounding Rock

A technology for crushing surrounding rocks and tunnels, applied in the field of tunnel support systems, can solve problems such as deformation, cracking and spalling of concrete sprayed layers, and uneven stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

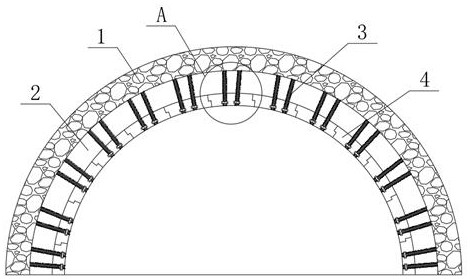

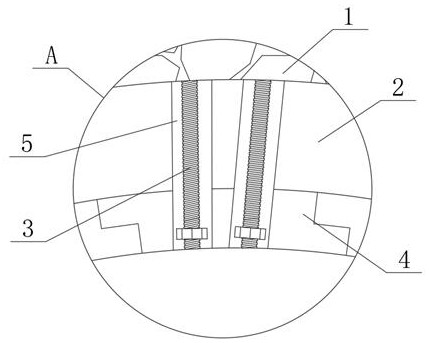

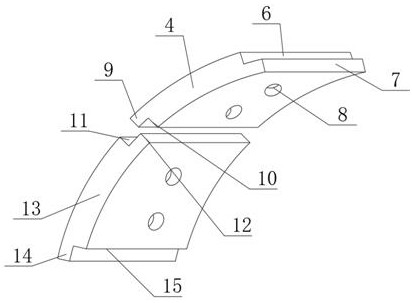

[0022] see Figure 1-5 , the present invention provides the following technical solutions: a tunnel support system suitable for weak and broken surrounding rocks, comprising a broken surrounding rock layer 1 and a primary support shotcrete layer 2, and The hollow spiral anchor rod 3 and the anchoring device 5 inside the concrete layer 2, the primary support shotcrete layer 2 is fixed with the first reinforced shotcrete layer reinforcing plate 4 and the No. 1 reinforced shotcrete layer reinforcing plate 13 through several anchoring devices 5, One end of the first enhanced sprayed concrete layer reinforcement plate 4 is integrally formed with a second bump 9, and one side of the second bump 9 on the outer surface of the first enhanced shotcrete layer reinforcement plate 4 is integrally formed with a second card groove 10, a One end of No. 1 reinforced shotcrete layer reinforcing plate 13 is integrally formed with a No. 1 bump 12, and one side of No. 1 No. 1 bump 12 on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com