A spiral meat grinder

A meat grinder and meat grinder technology, applied in grain processing and other directions, can solve the problems of difficult structure disassembly, bacteria breeding, food contamination, etc., and achieve the effects of improving meat grinding efficiency, ensuring cleanliness, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

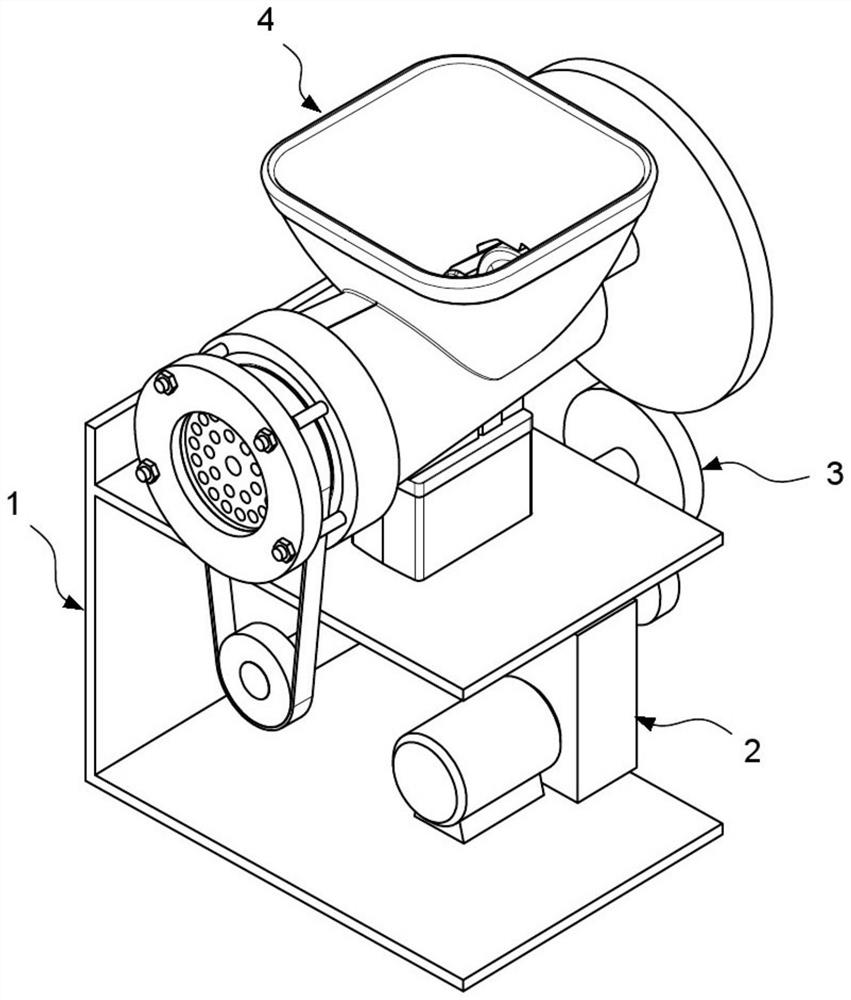

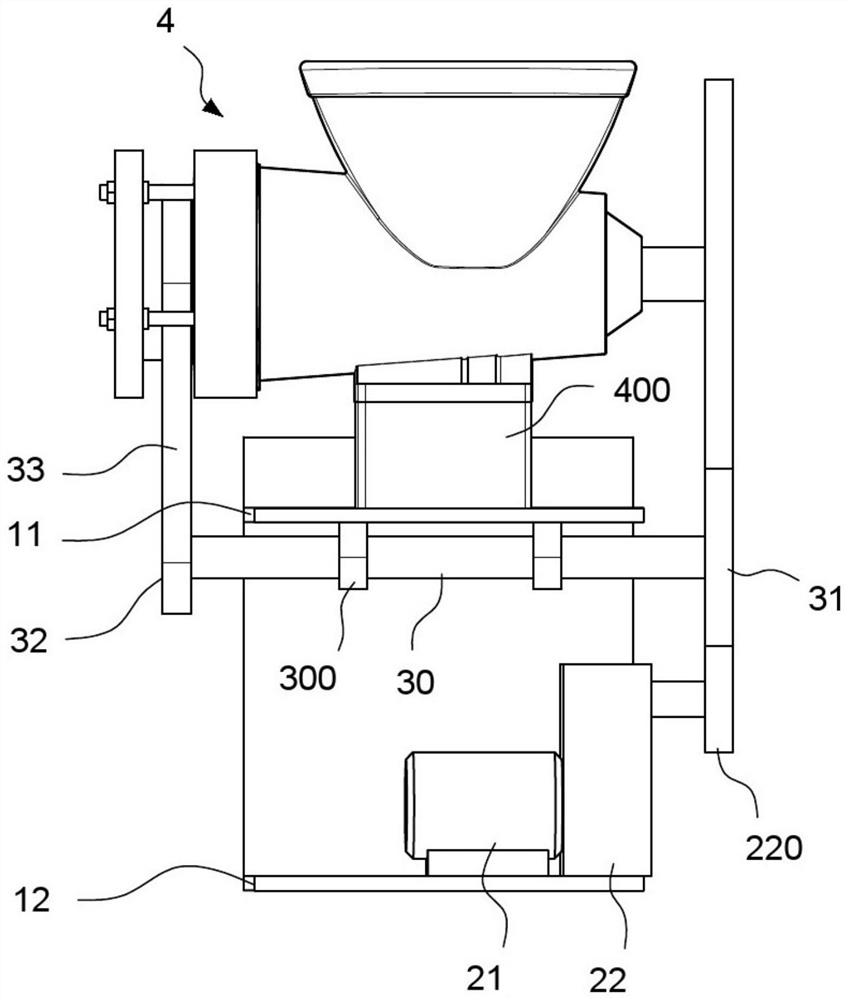

[0034] Such as figure 1 — Figure 7 As shown, the invention provides a kind of spiral meat grinder, comprising:

[0035] A support base 1, which is fixedly seated on the ground, and the support base 1 includes an upper support plate 11 and a lower support plate 12;

[0036] A meat grinding unit 4, which is fixedly installed on the top of the upper support plate 11, for grinding the meat to be processed; and

[0037] A drive unit, which is fixedly installed on the top of the lower support plate 12, is used to supply meat grinding power to the meat grinding unit 4;

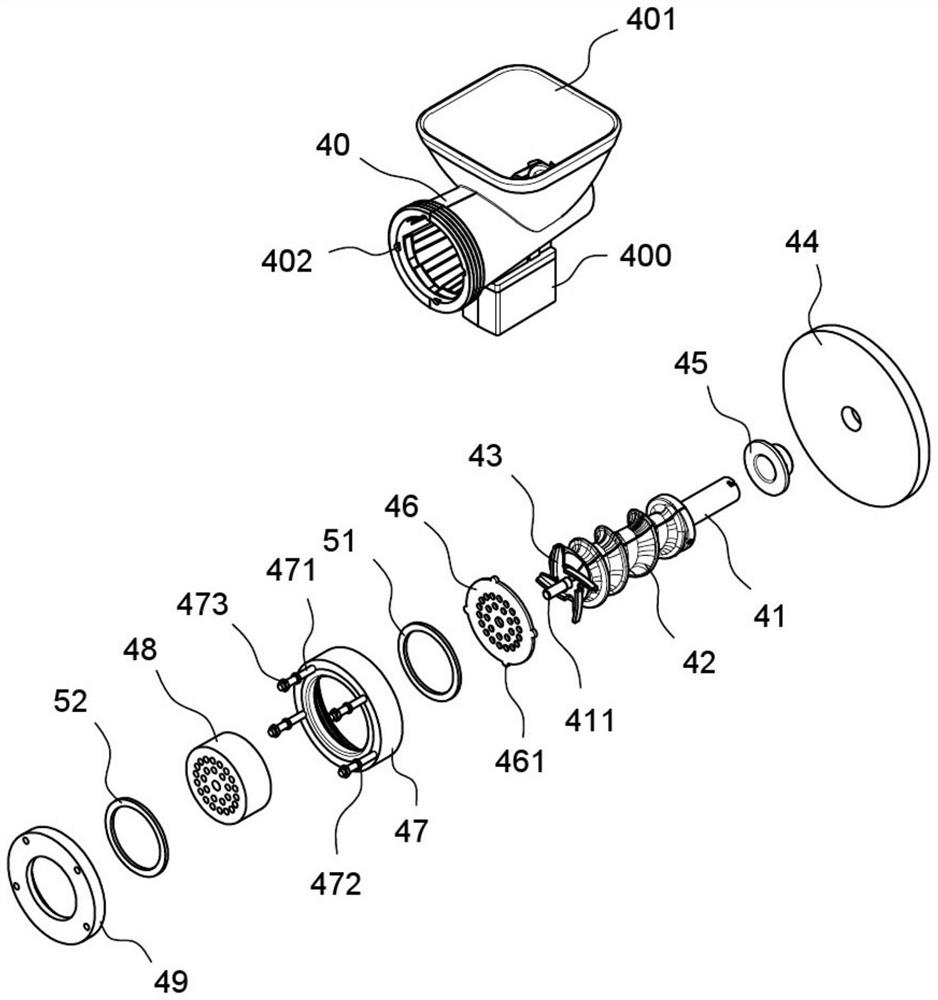

[0038] Wherein, the meat grinding unit 4 includes a meat grinding housing 40, a conveying screw 42 rotatably installed in the meat grinding housing 40, a reamer 43 fixed on the front end of the conveying screw 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com