Movable dust collection device for electromechanical machining

A dust suction device and mobile technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as clogging and inability to filter impurities, and achieve the effect of improving work efficiency and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

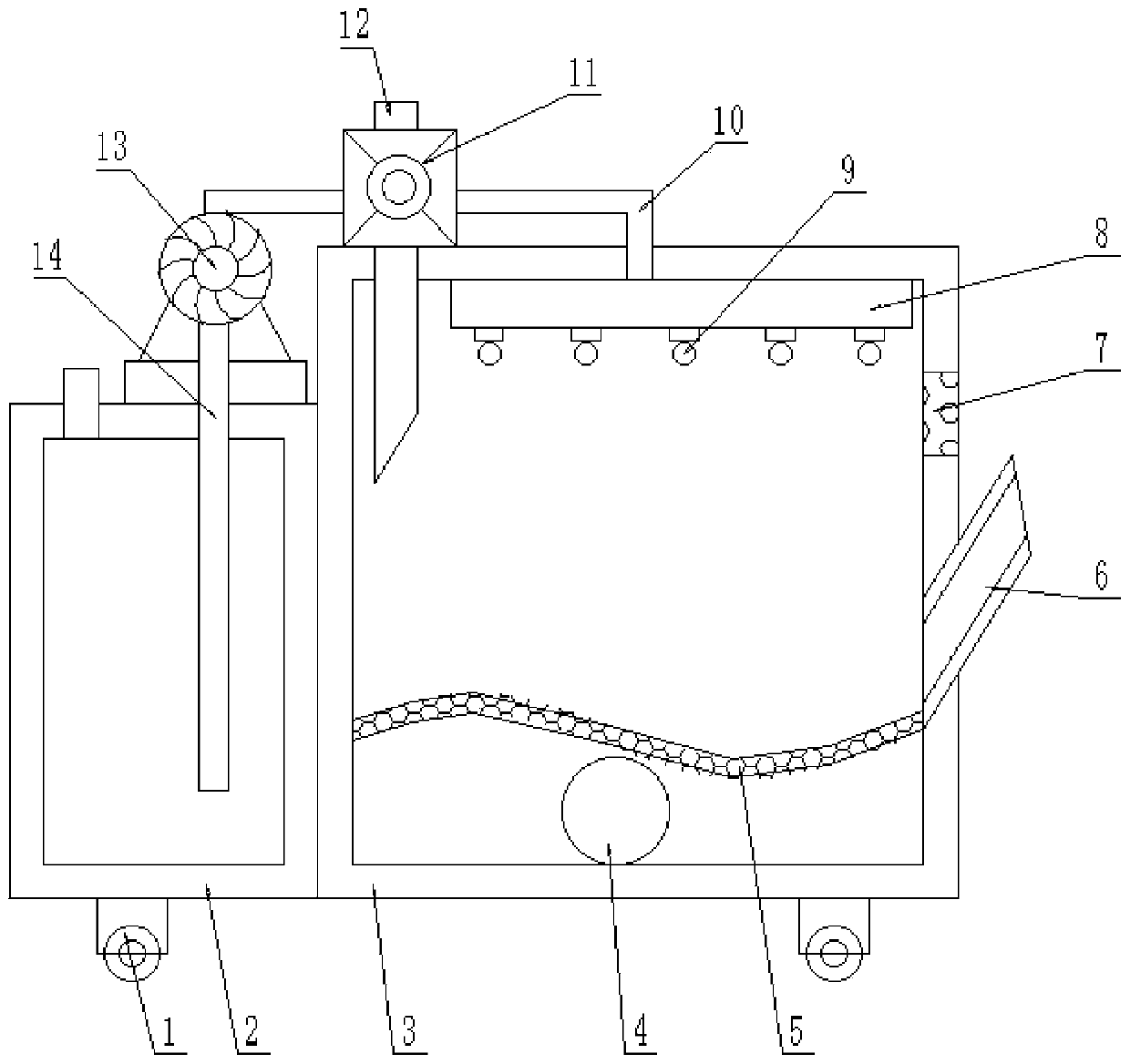

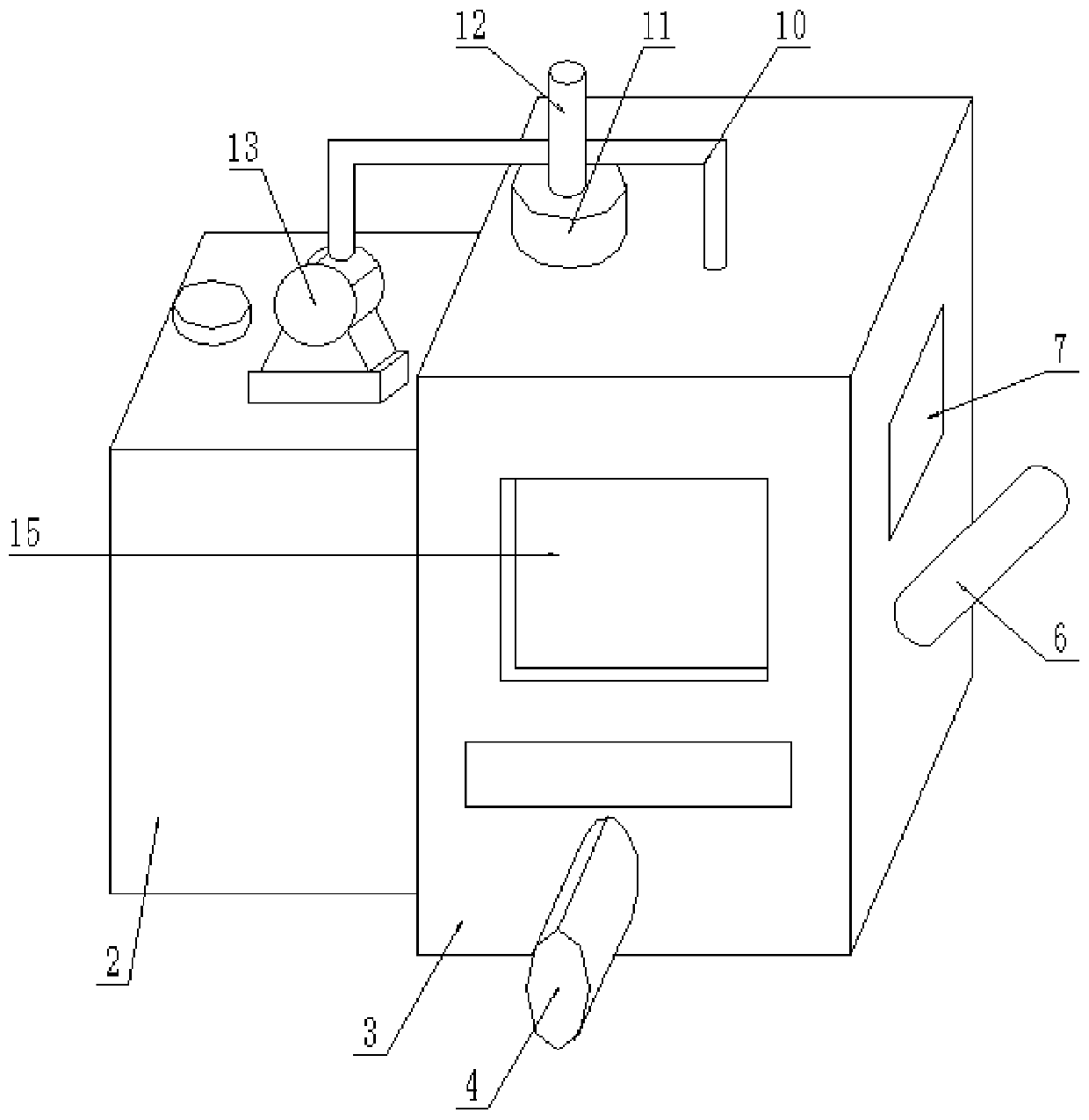

[0023] refer to figure 1 and figure 2 , a mobile vacuum device for electromechanical processing, including a water tank 2 and a box body 3, the bottom of the water tank 2 and the box body 3 are fixed with a plurality of wheels 1 by bolts, and the top outer wall of the water tank 2 is fixed by bolts There is a water pump 13, a water inlet pipe 14 is welded on the inner wall of the water inlet of the water pump 13, and a connecting pipe 10 is welded on the inner wall of the water outlet of the water pump 13, the bottom of the connecting pipe 10 is connected with the water outlet pipe 8, and the top of the box body 3 is fixed by bolts There is an air inlet fan 11, and the output end of the air inlet fan 11 is welded with an air inlet pipe 12, and the bottom of the air inlet pipe 12 is welded with the box body 3.

[0024] The water outlet pipe 8 is fixed on the top inner wall of the box body 3 by bolts, and the bottom of the water outlet pipe 8 is fixed with a plurality of nozzl...

Embodiment 2

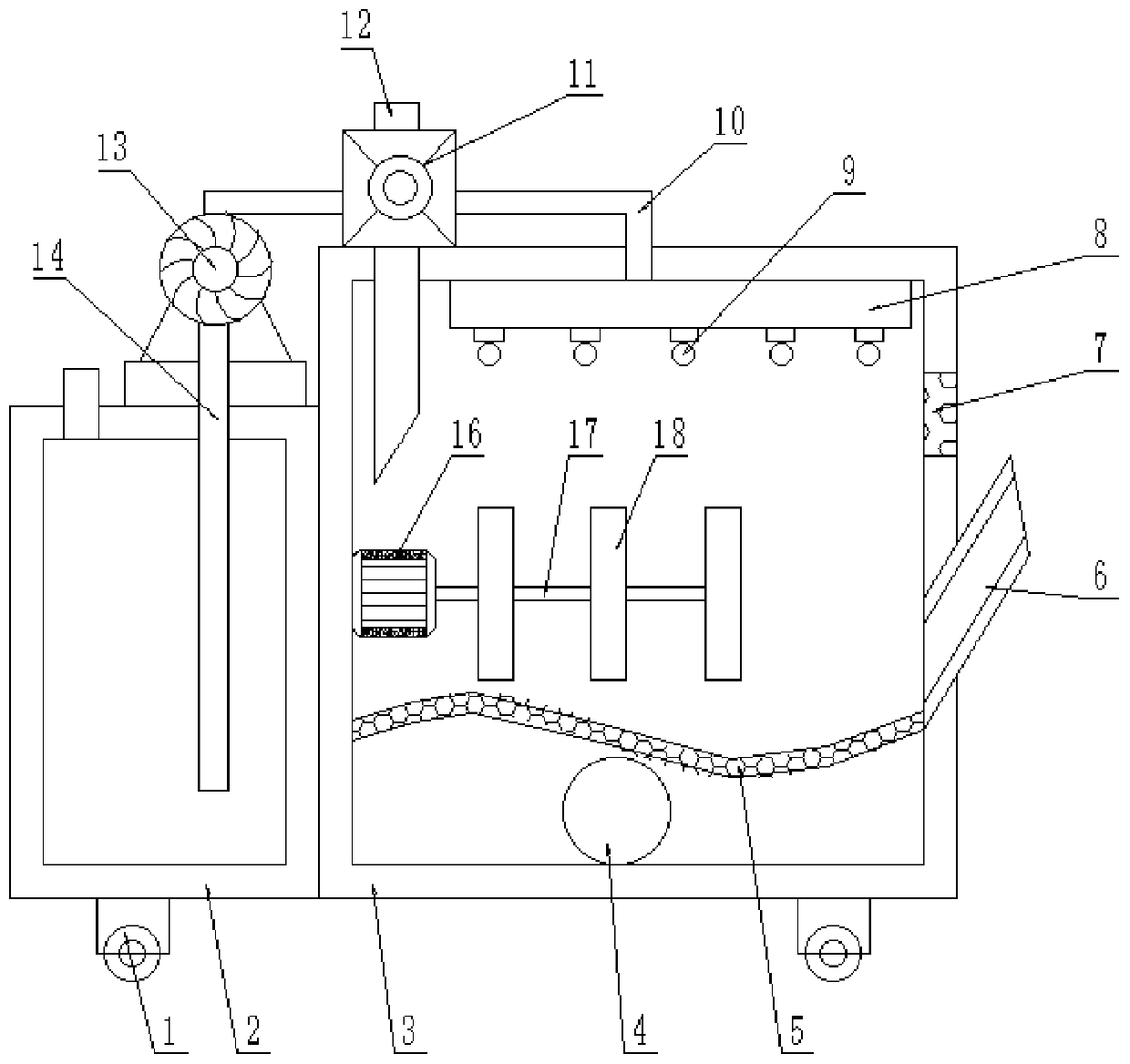

[0027] refer to image 3 , a mobile vacuum device for electromechanical processing. Compared with Embodiment 1, the main difference of this embodiment is that this embodiment also includes a submersible motor 16, which is fixed on one side of the box body 3 by bolts. On the inner wall, and one end of the output shaft of the submersible motor 16 is welded with a transmission rod 17, and one side of the transmission rod 17 is fixed with a plurality of stirring plates 18 by bolts.

[0028] The working principle of this embodiment: drive the transmission rod 17 and the stirring plate 18 to rotate through the submersible motor 16, promote the water flow in the box body 3, prevent impurities from adhering to the filter screen plate 5, and affect its normal drainage work, and can also Drive the circulation of air, so that the dust can be fully washed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com