Production method suitable for pickup head for microchip mass transfer

A production method and pick-up head technology, which is applied in the direction of measuring device casing, semiconductor/solid-state device testing/measurement, conveyor objects, etc., can solve the problems of low handling efficiency and achieve the effect of increasing handling speed and chip spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

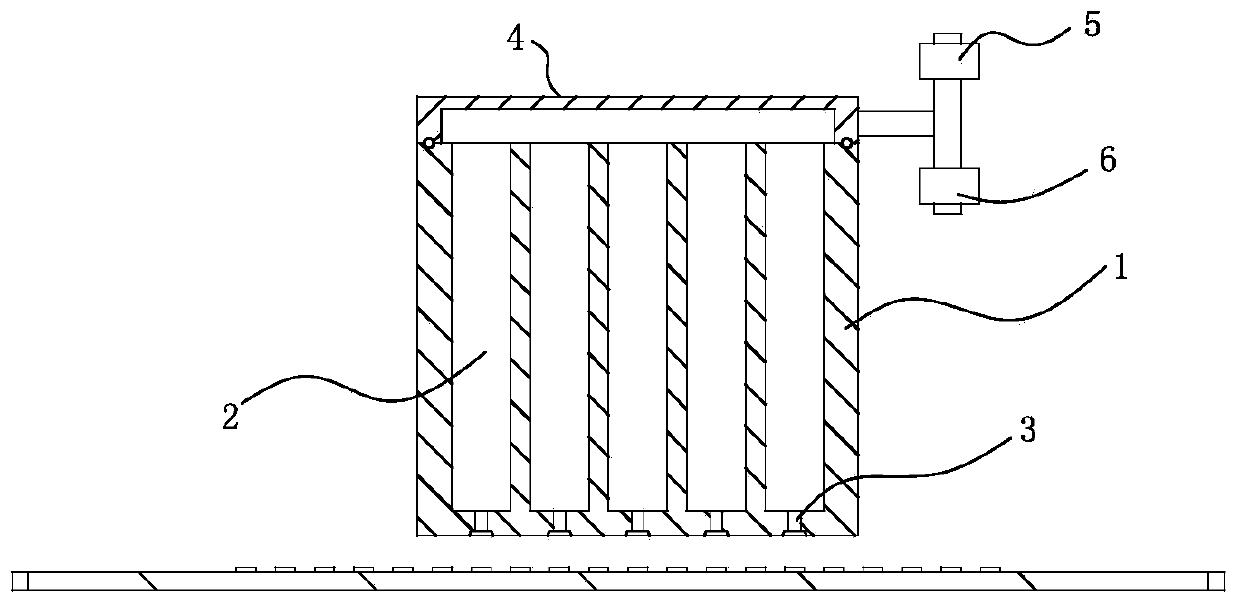

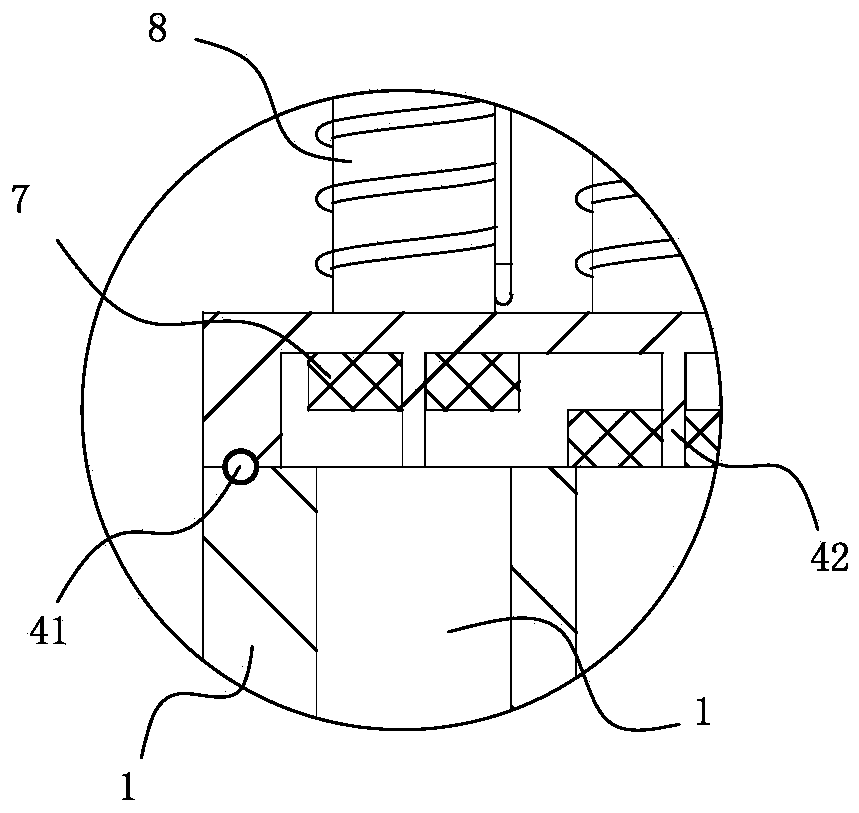

[0022] Example 1: see figure 1 , a production method suitable for mass transfer pick-up heads for microchips, this type of pick-up head is suitable for picking up microchips with a specification of 5-100 microns. Step 1: Use ceramic sintering technology to sinter the columnar pick-up head 1 at one time. The upper end surface of the pick-up head 1 is sintered downward at the same time to form M×N air channels 2 that are independent of each other and have a pore size of 100-1000 microns. Road 2 is provided with a blind hole; step 2, between the lower end of each air channel 2 and the lower end surface of the pick-up head 1, a micro air channel 3 with a diameter of 3 to 5 microns is connected (see Figure 4 ), the micro-air channel 3 can be processed directly on the lower end surface of the pick-up head 1 by laser drilling technology, or by an etching process (see Figure 6 and Figure 7 ), this process also needs to first process a positioning sinker 13 on the lower end surfac...

Embodiment 2

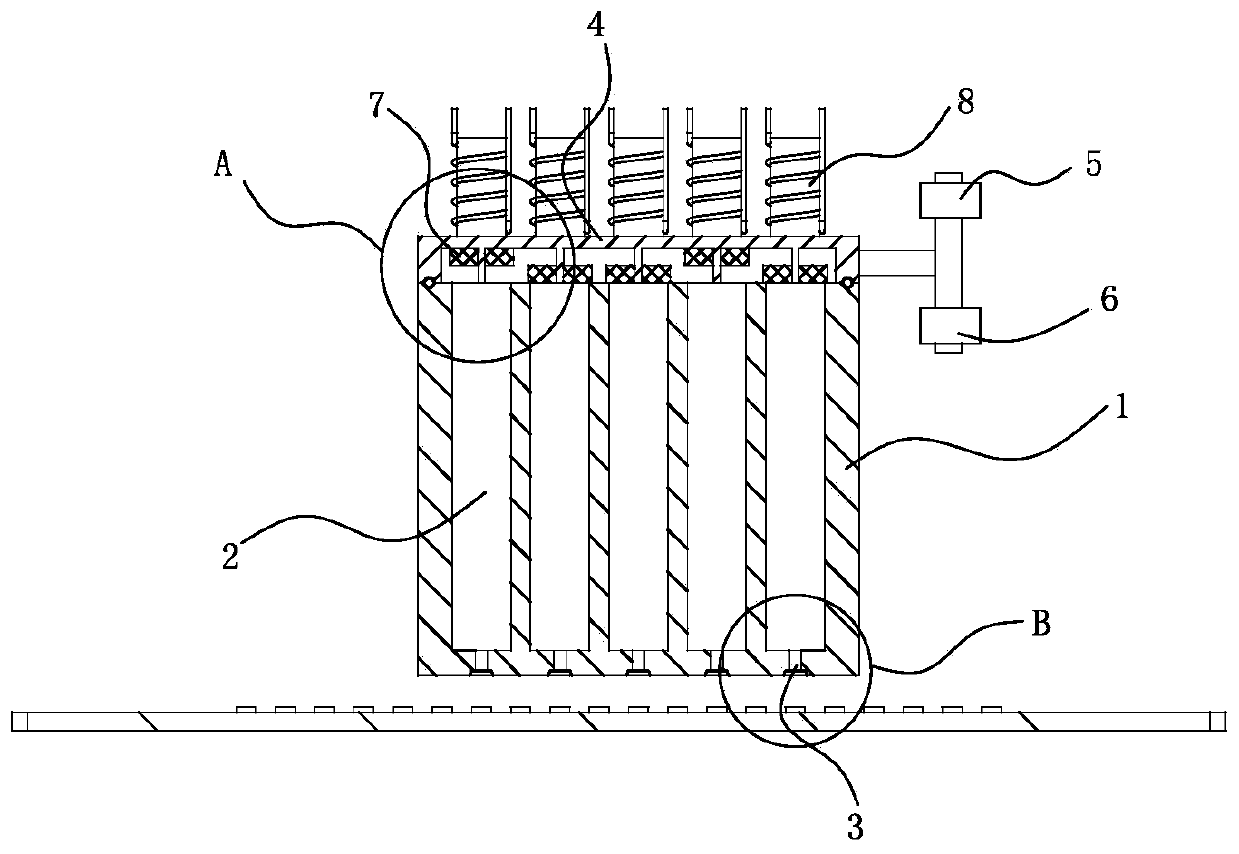

[0023] Example 2: see figure 2, a production method suitable for mass transfer pick-up heads for microchips, this type of pick-up head is suitable for picking up microchips with a specification of 5-100 microns. Step 1: Use ceramic sintering technology to sinter the columnar pick-up head 1 at one time. The upper end surface of the pick-up head 1 is sintered downward at the same time to form M×N air channels 2 that are independent of each other and have a pore size of 100-1000 microns. Road 2 is set as a blind hole; Step 2, between the lower end of each air channel 2 and the lower end surface of the pick-up head 1 is connected with a micro air channel 3 with a diameter of Figure 4 ), the micro-air channel 3 can be processed directly on the lower end surface of the pick-up head 1 by laser drilling technology, or by an etching process (see Figure 6 and Figure 7 ), this process also needs to first process a positioning sinker 13 on the lower end surface of the pickup head 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com