Temperature-variable abrasion instrument capable of studying rolling and sliding friction behaviors of rubber simultaneously

A sliding friction and behavior technology, used in instruments, scientific instruments, testing wear resistance, etc., can solve the problems of a single form of rubber friction, the inability to reproduce the friction behavior between tires and the ground, and the inability to realize rolling and sliding friction at the same time. To achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

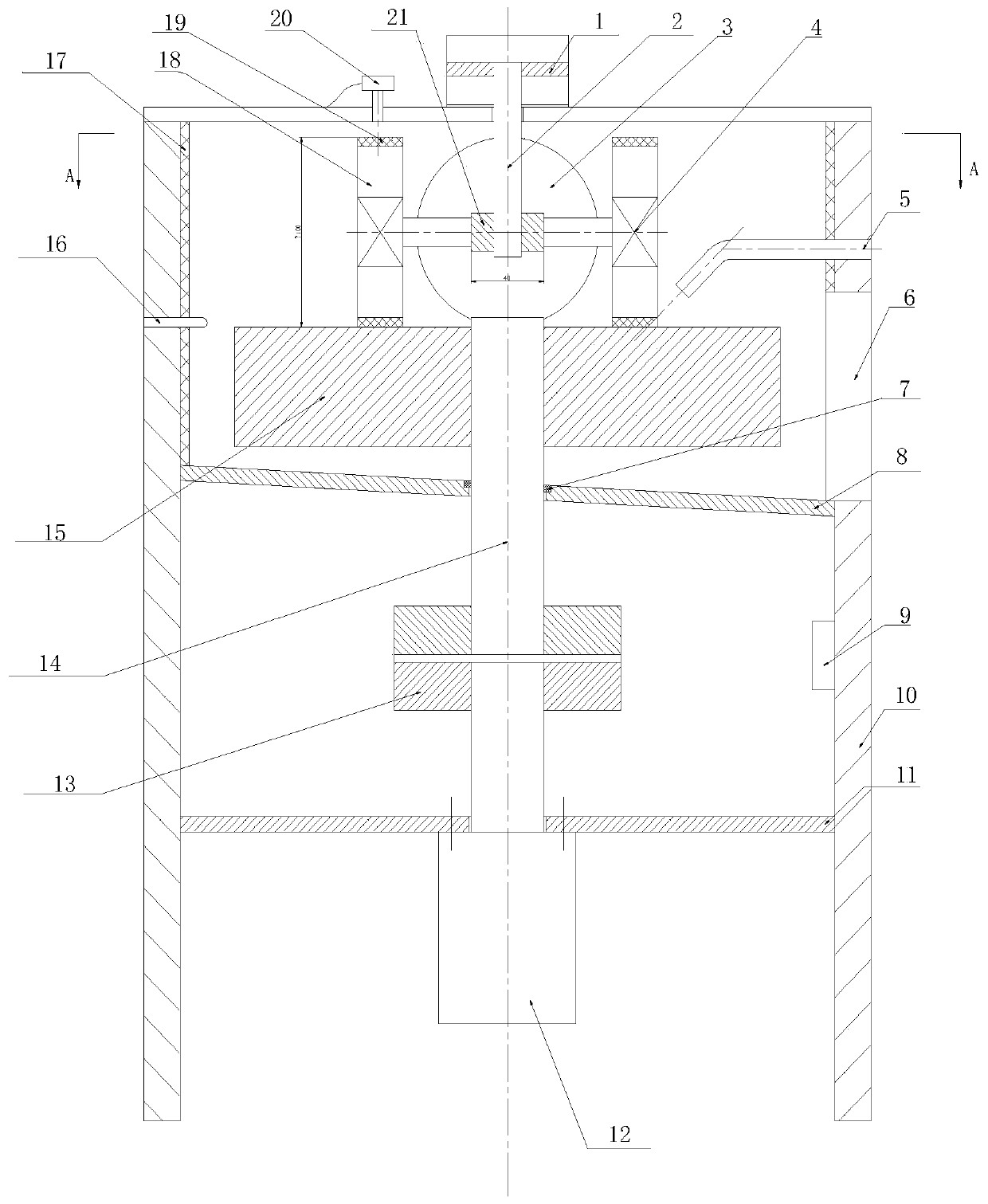

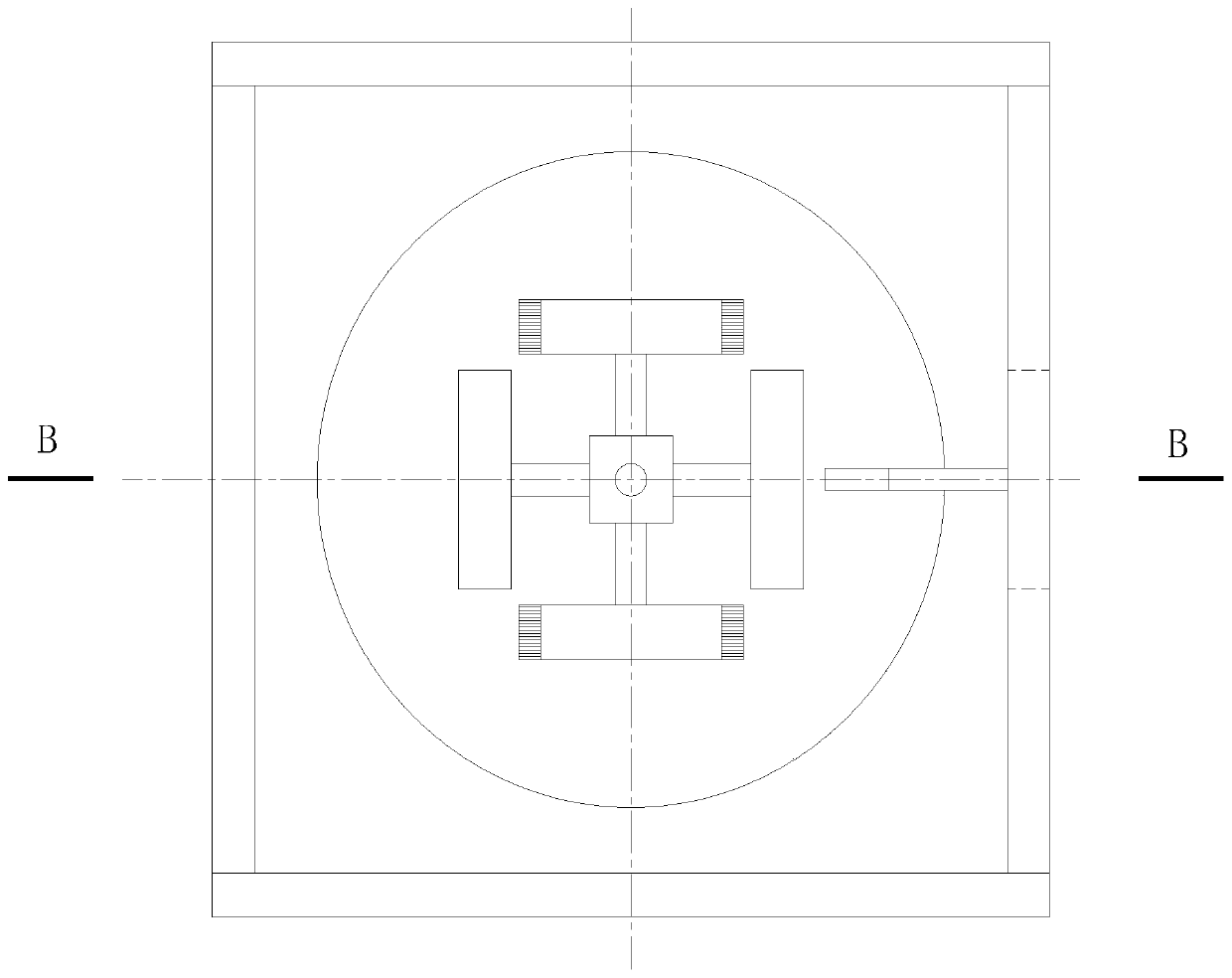

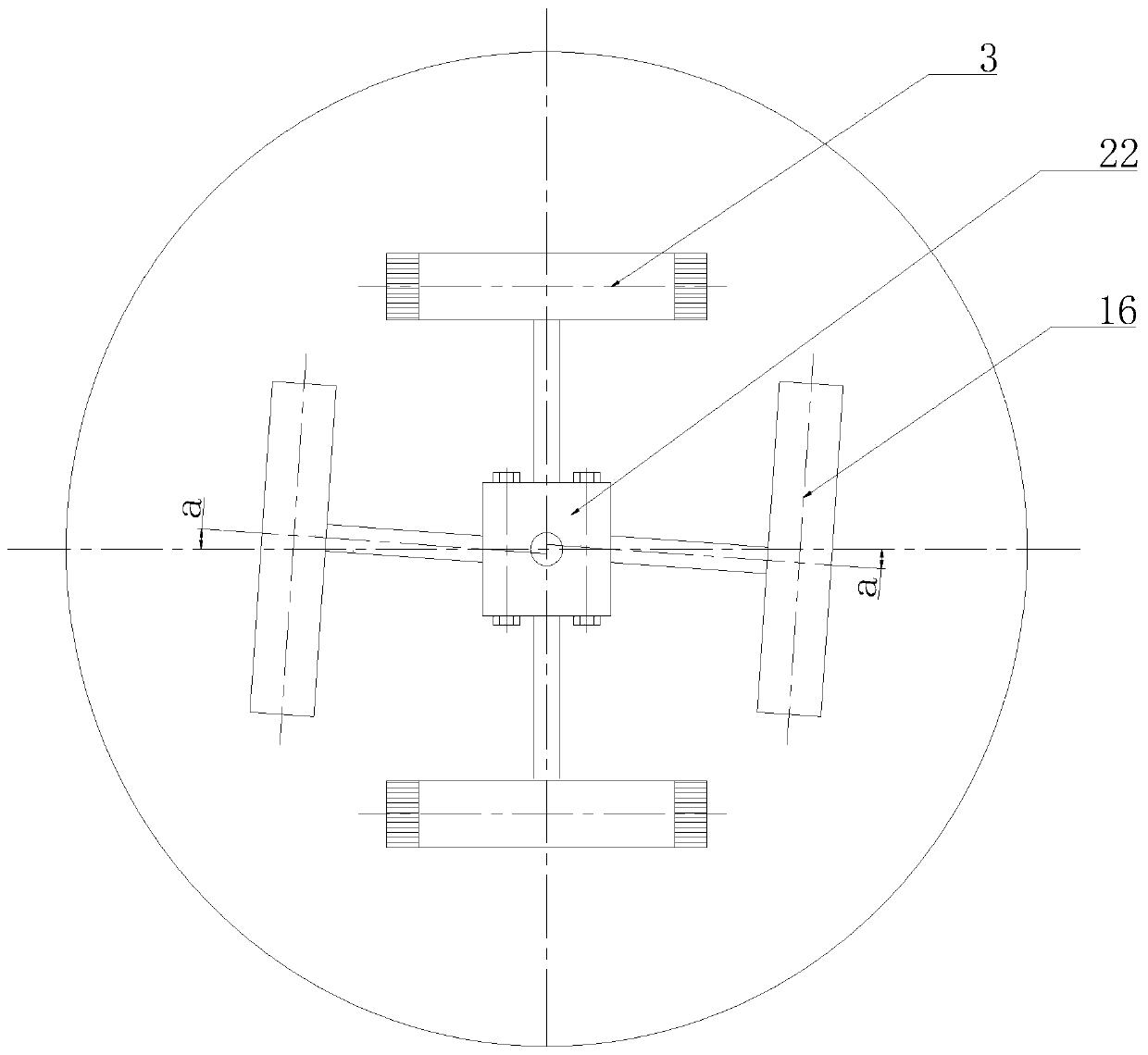

[0027] The following is a specific description of the temperature-variable abrasion tester proposed by the present invention that can simultaneously measure rubber rolling friction and sliding friction behavior according to the accompanying drawings.

[0028] Such as figure 1 As shown in -3, the variable temperature wear instrument that can simultaneously measure rubber rolling friction and sliding friction behavior involved in the present invention consists of a cylinder 1, a piston rod 2, a cleaning wheel 3, a bearing 4, an air intake pipe 5, a glass window 6, and a rubber sealing ring 7 , collecting plate 8, counter 9, bracket 10, motor fixing plate 11, motor 12, coupling 13, spindle 14, grinding wheel 15, thermocouple 16, heating plate 17, abrasive wheel 18, rubber ring 19, high-speed camera 20 and The cross connecting plate 21 forms. The piston rod 2 in the cylinder 1 is connected with the abrasive wheel 18 with the rubber ring 19 and the cleaning wheel 3 which are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com