Leakage blocking method for bolt holes of shield tunnel segments

A shield tunnel segment and bolt hole technology, which is applied to tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of repeated water leakage, difficulty in sealing leakage, and easy water seepage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

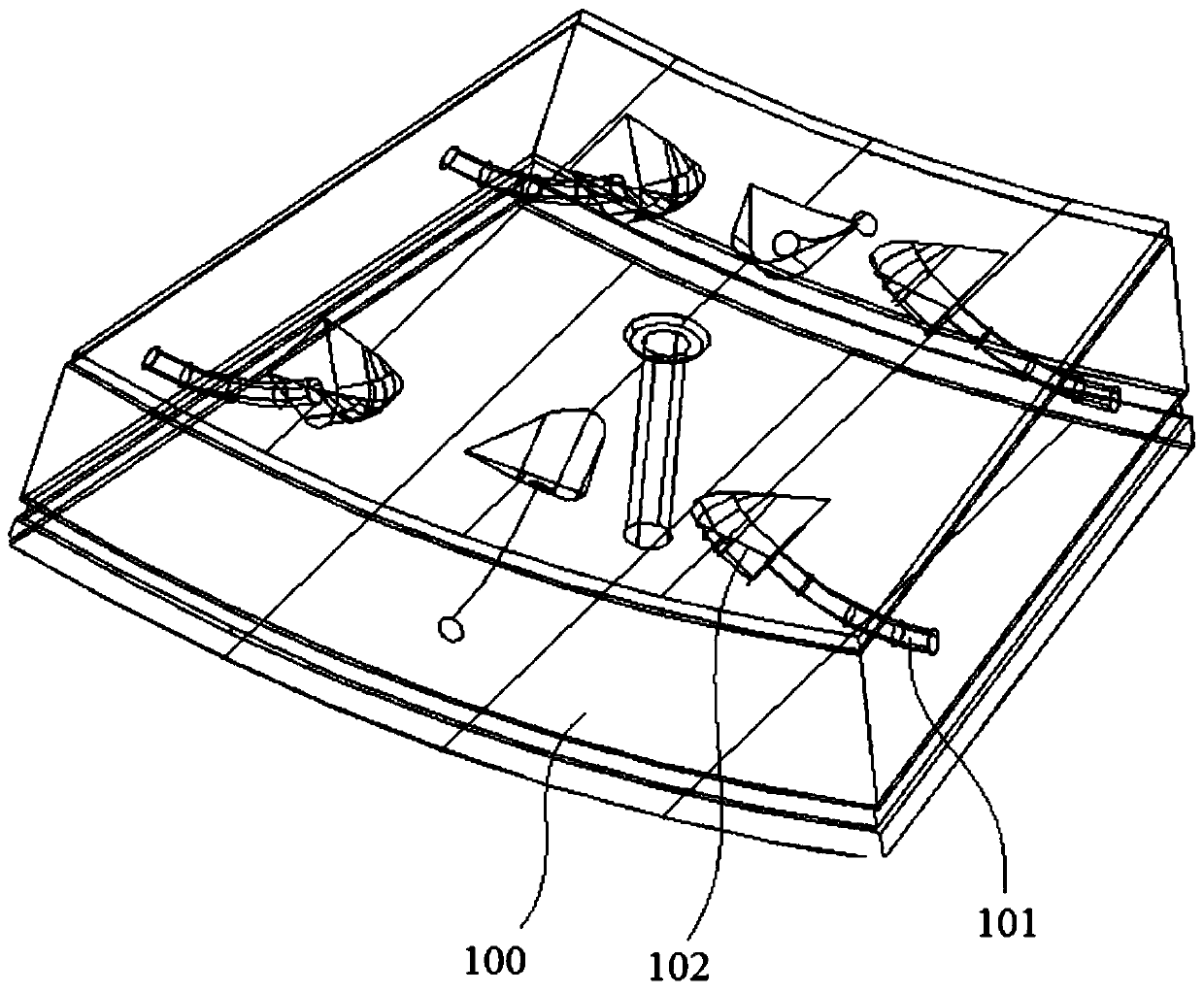

[0073] The embodiment of the present application provides a method for plugging the leakage of bolt holes in a shield tunnel segment, which includes the following steps:

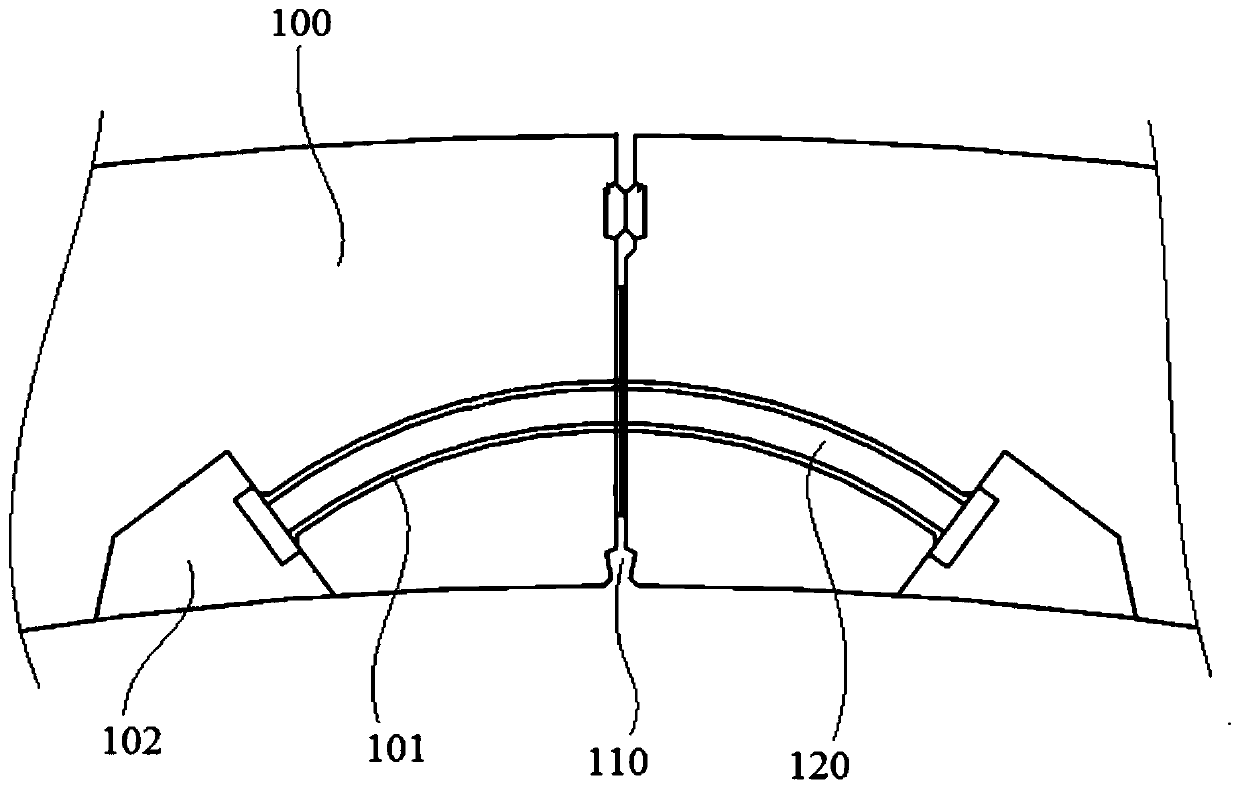

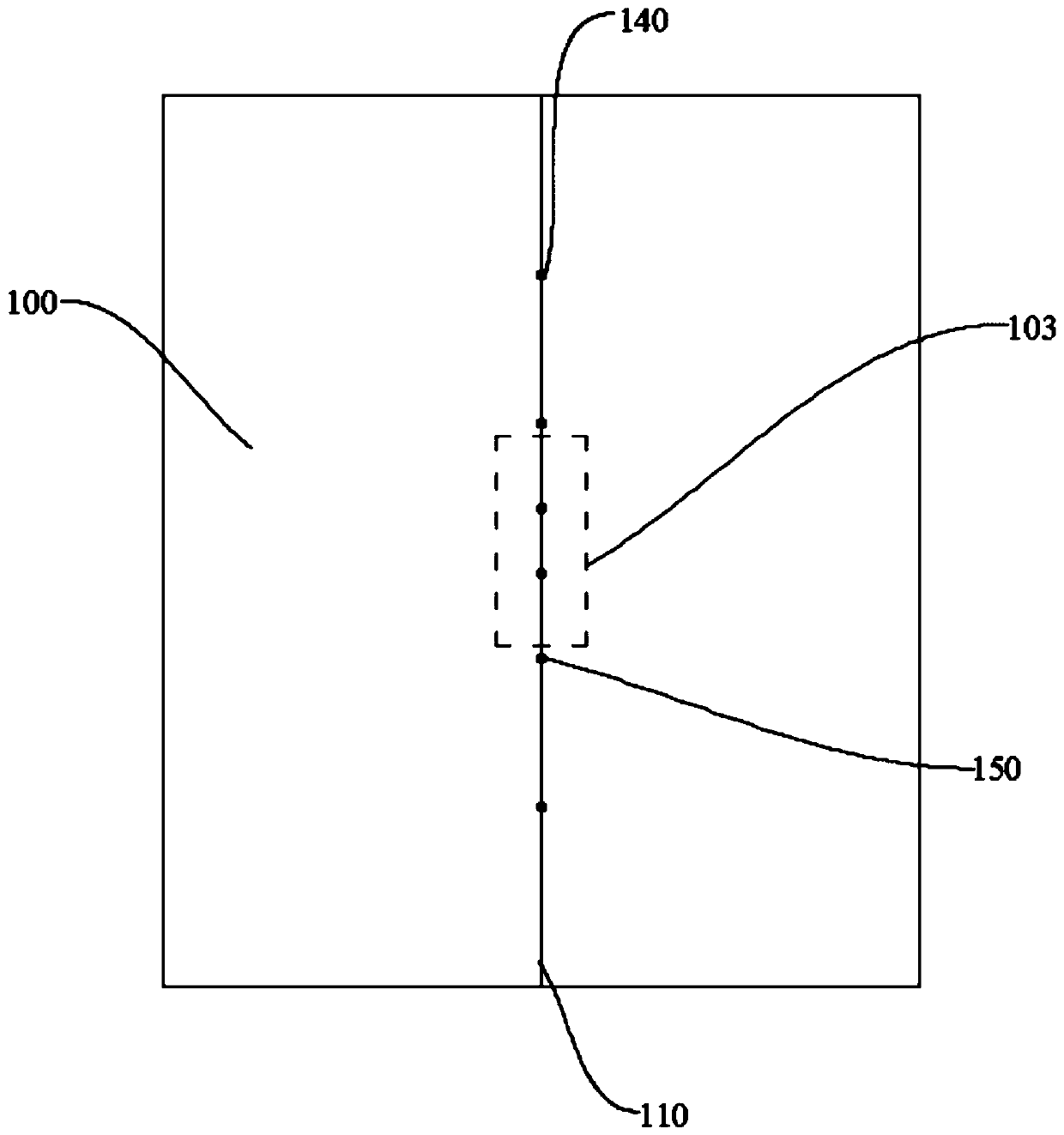

[0074] 1. If image 3 As shown, the closest seam 110 of the leaking bolt hole 101 is blocked; it includes:

[0075] 1.1. First, look for the leak 103 in the seam 110 closest to the bolt hole 101 where the leakage occurs, and then extend 60 cm outward along the seam 110 at both ends of the leak 103 in the seam 110 Drill to the inside of the splicing joint 110 to form isolation holes with a diameter of 15 mm and a hole depth of 53 cm, and extend the two isolation holes to the EPDM rubber gasket set in the splicing joint 110, and then press back The epoxy-modified polysulfide sealant is poured into the two isolation holes respectively by the type glue injection process, and is cured to form two isolation columns 140 to isolate the two ends of the leak 103 in the splicing seam 110 .

[0076] 1.2. After isolati...

Embodiment 2

[0086] Embodiment 2 provides a kind of leakage plugging method of shield tunnel segment bolt hole, which comprises the following steps:

[0087] 1. Seal the joints closest to the leaking bolt holes; including:

[0088] 1.1. First, look for the leak in the seam closest to the bolt hole where the leakage occurs, and then extend 60cm outward along the seam at both ends of the leak in the seam to the inside of the seam Drill and form an isolation hole with a diameter of 12mm and a depth of 54cm, and extend the two isolation holes to the EPDM rubber gasket set in the splicing joint, and then fill the two isolation holes with nylon elastomer to form Two spacer posts to isolate both ends of the leak in the joint.

[0089] 1.2. After isolating the two ends of the leak in the joint, dig the leak, and use aluminate micro-expansion quick-drying cement to seal the surface of the leak. After the surface of the leak is sealed, observe the leak Whether there is water seepage outside the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com