Warp knitting machine

A warp knitting machine and frame technology, applied in the field of warp knitting machines, can solve the problems of troublesome installation and large number of single parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

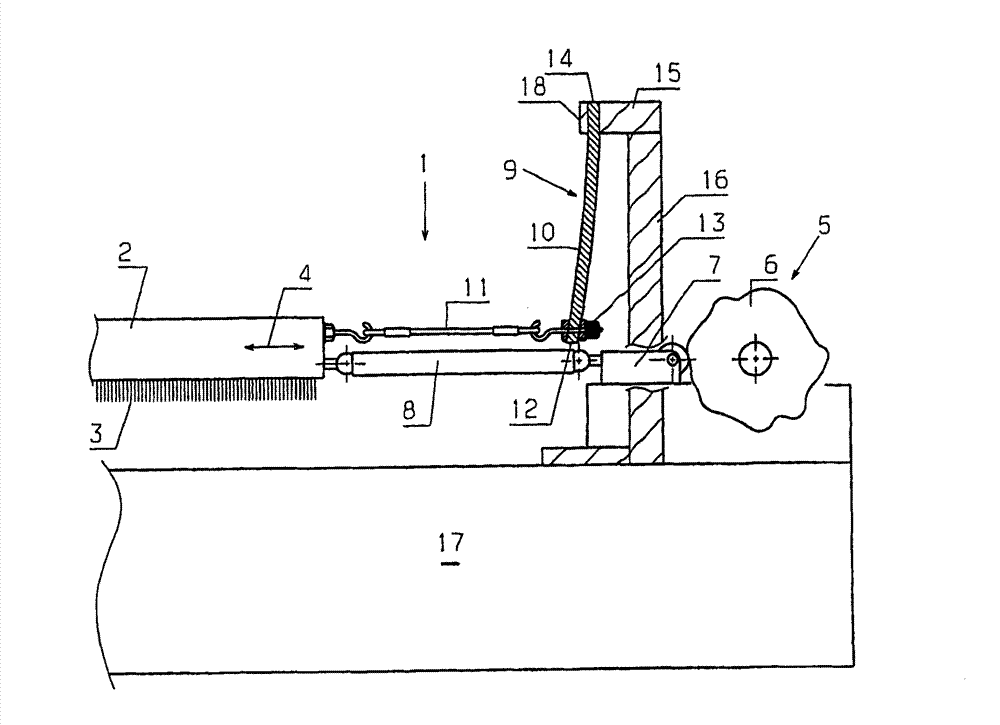

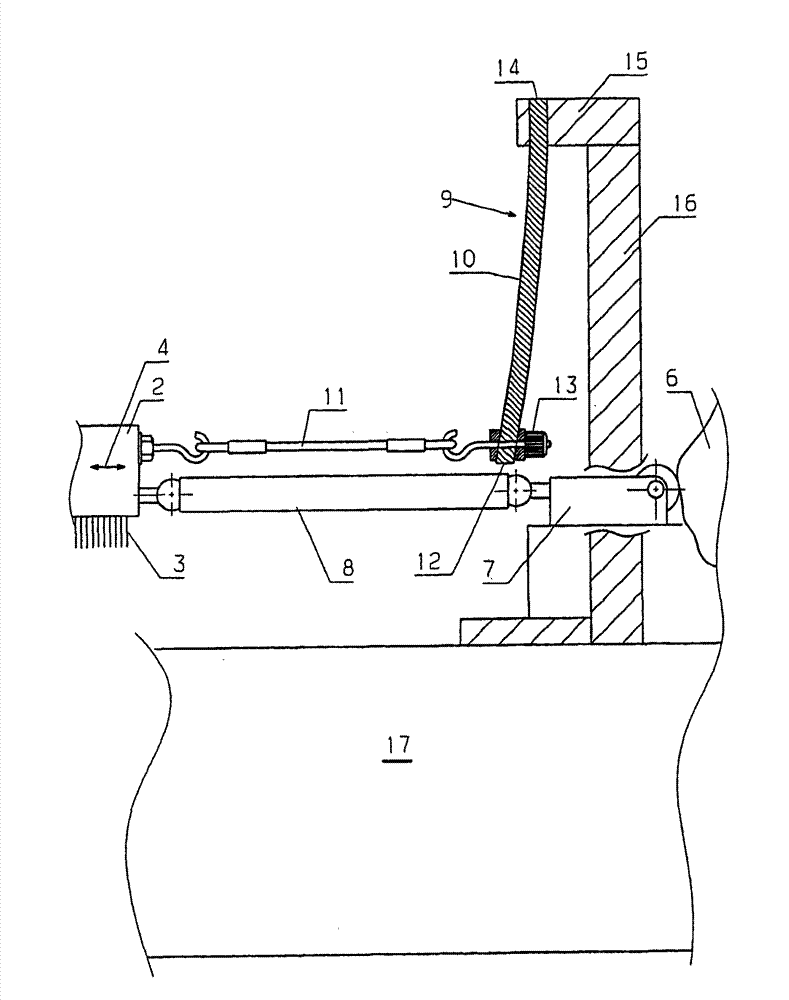

[0025] figure 1 A section of the warp knitting machine 1 is shown in extremely simplified form. Only the yarn guide bar 2 with the yarn guide needle 3 is shown in the figure. For the sake of simplicity, the needle bar and other bars with knitting needles are not shown in the figure.

[0026] During operation, the thread guide bar 2 must be moved back and forth in the traverse direction 4 , that is to say parallel to the longitudinal direction of the thread guide bar 2 . The traversing direction 4 is indicated by a double arrow. Furthermore, as is known per se, the thread guide bar 2 for loop formation is deflected back and forth perpendicular to the plane of the drawing. For the sake of brevity, the means for causing the above-mentioned movements are also not shown in the figure.

[0027] The movement in the traversing direction 4 , hereinafter also referred to as “traversing movement”, is brought about by the thread guide bar drive 5 , which has a jacquard disc 6 , which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com