Propulsion method for shield machine to pass through shallow-buried underground excavation tunnel

A shield machine and underground excavation technology, applied in tunnels, roads, tracks, etc., can solve problems such as dismantling and hoisting of shield machines, and achieve the effects of shortening the construction period, simplifying the propulsion work, and reducing mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

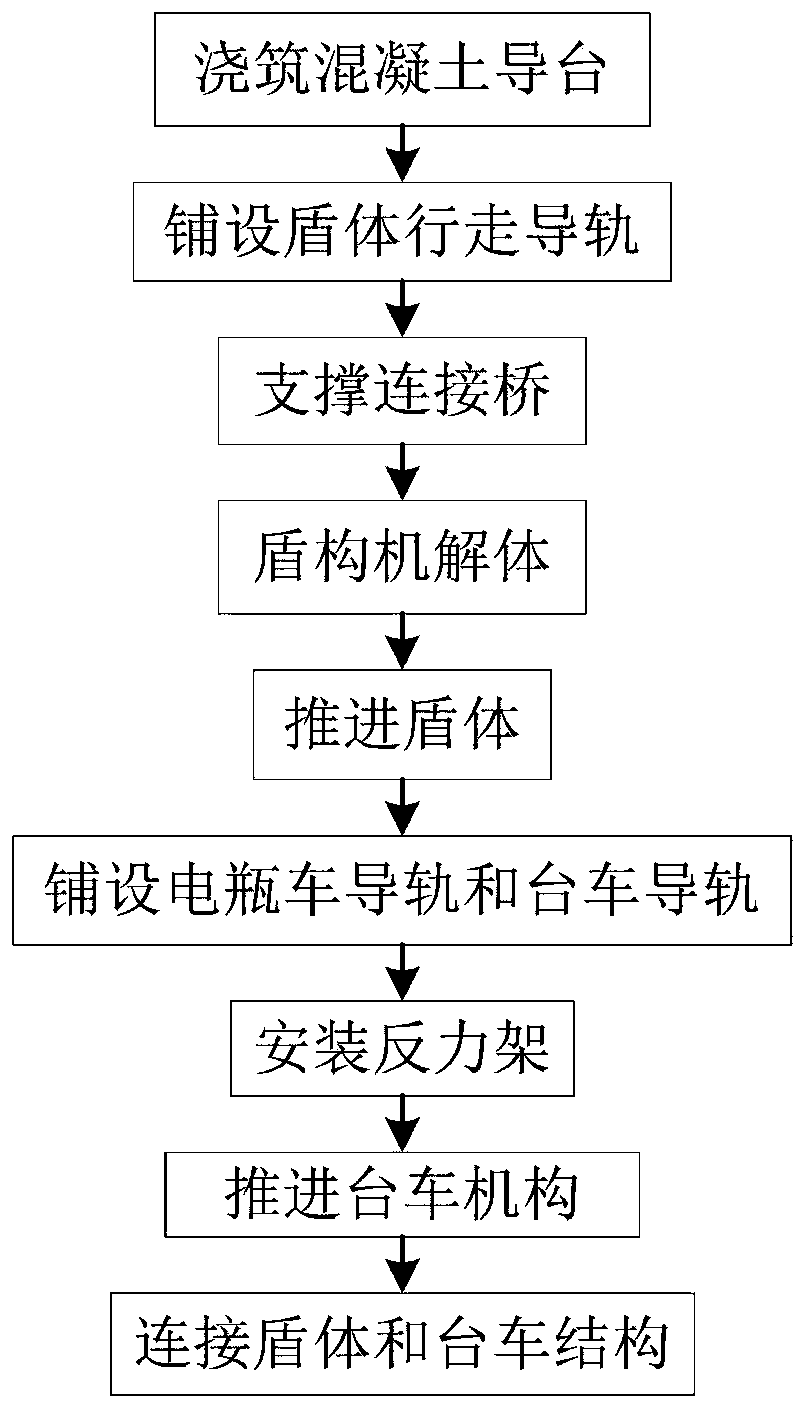

[0049] like figure 1 Shown is a method for propulsing a shield machine through a shallow-buried underground excavation tunnel. The shield machine includes a shield body 9 and a trolley structure. The trolley structure is composed of a trolley 6 and a connecting bridge 5. The concealed Tunnel digging 1 includes a propulsion section 1-1 connected to the exit opening of the last shield section 14 and a transition section 1-2 connected to the entry opening of the next shield section 18. The propulsion section 1-1 is provided with The mark 21 of the small mileage end of the reaction force frame, the mark 21 of the small mileage end of the reaction force frame is set on the side close to the transition section 1-2, and the propulsion method includes the following steps:

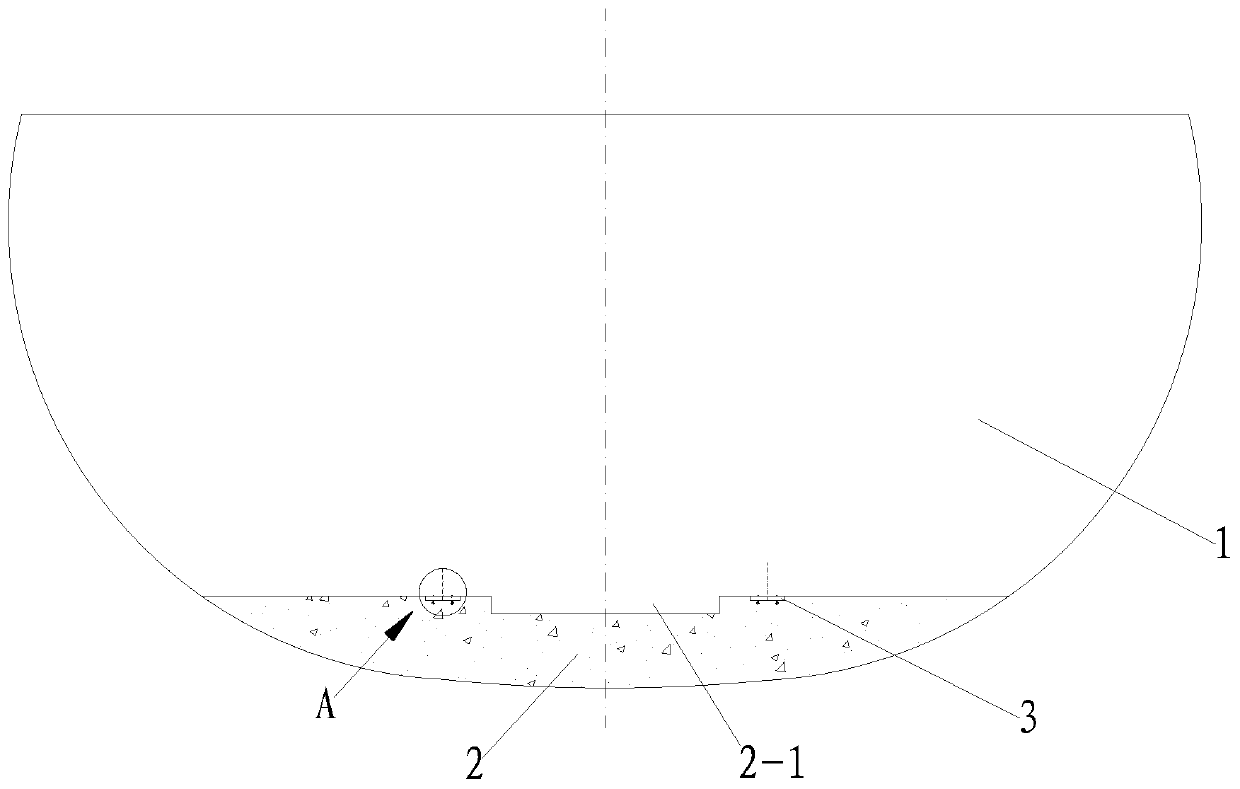

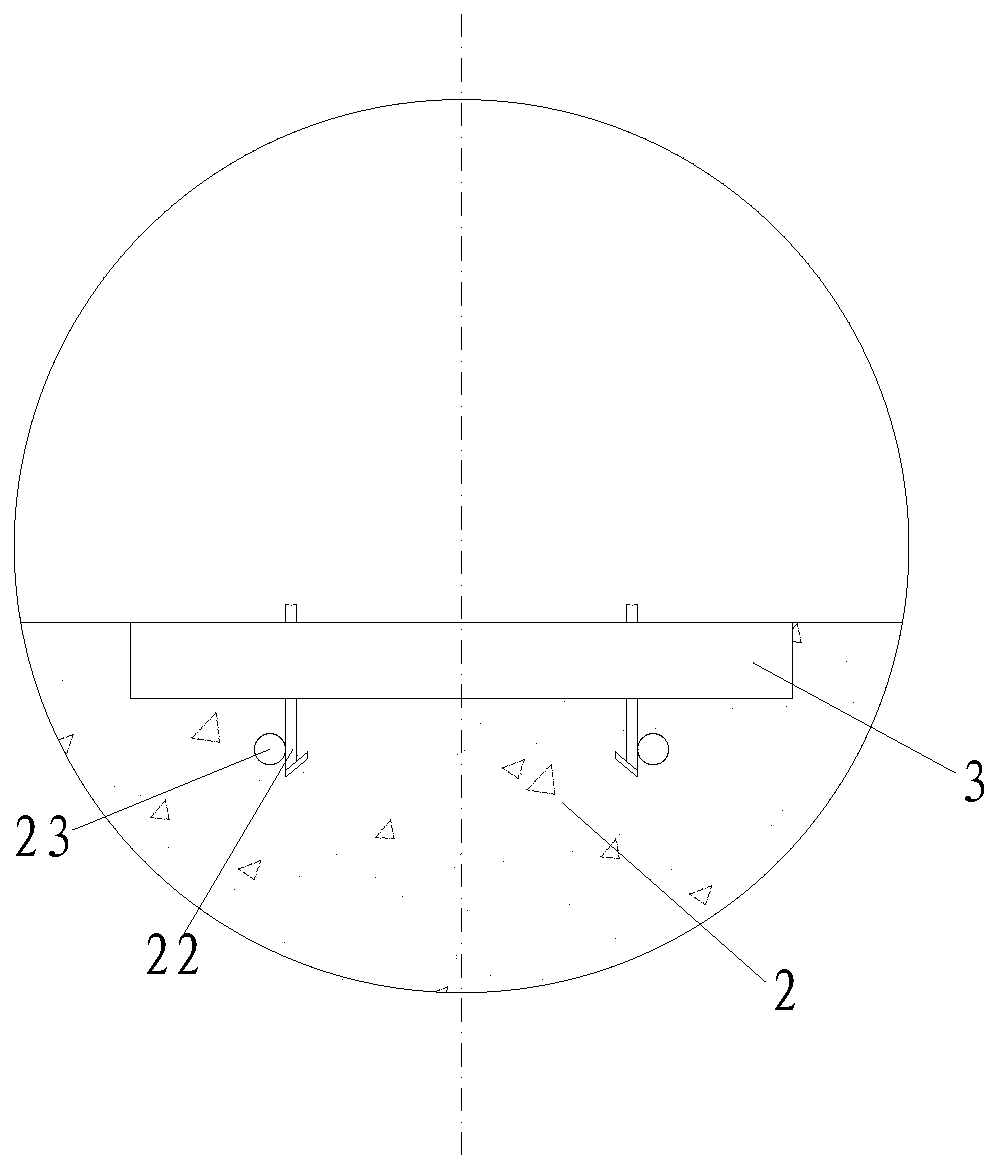

[0050] like figure 2 As shown, step 1, pouring the concrete guide platform: pouring the concrete guide platform 2 on the second lining at the bottom of the underground excavation tunnel 1, using the concrete guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com