Supercritical fluid foaming method for polypropylene material

A technology of supercritical fluid and polypropylene material, applied in the field of polymer foaming, can solve the problems of low foaming production efficiency and narrow foaming interval, and achieve the effects of shortening the saturation time, reducing the reject rate and widening the temperature interval.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

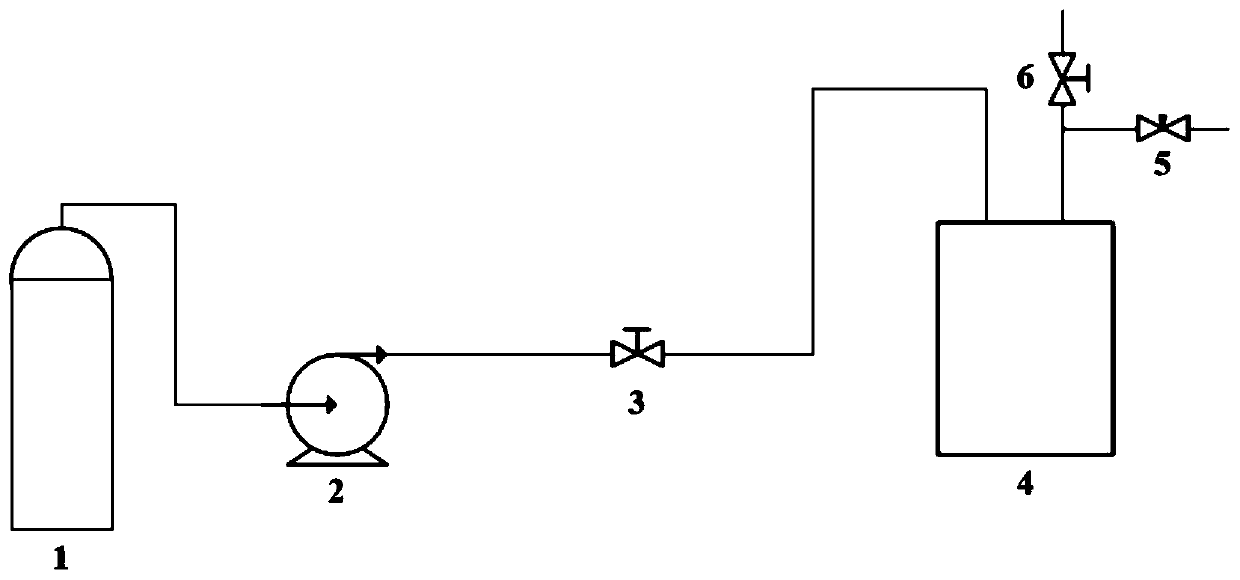

Method used

Image

Examples

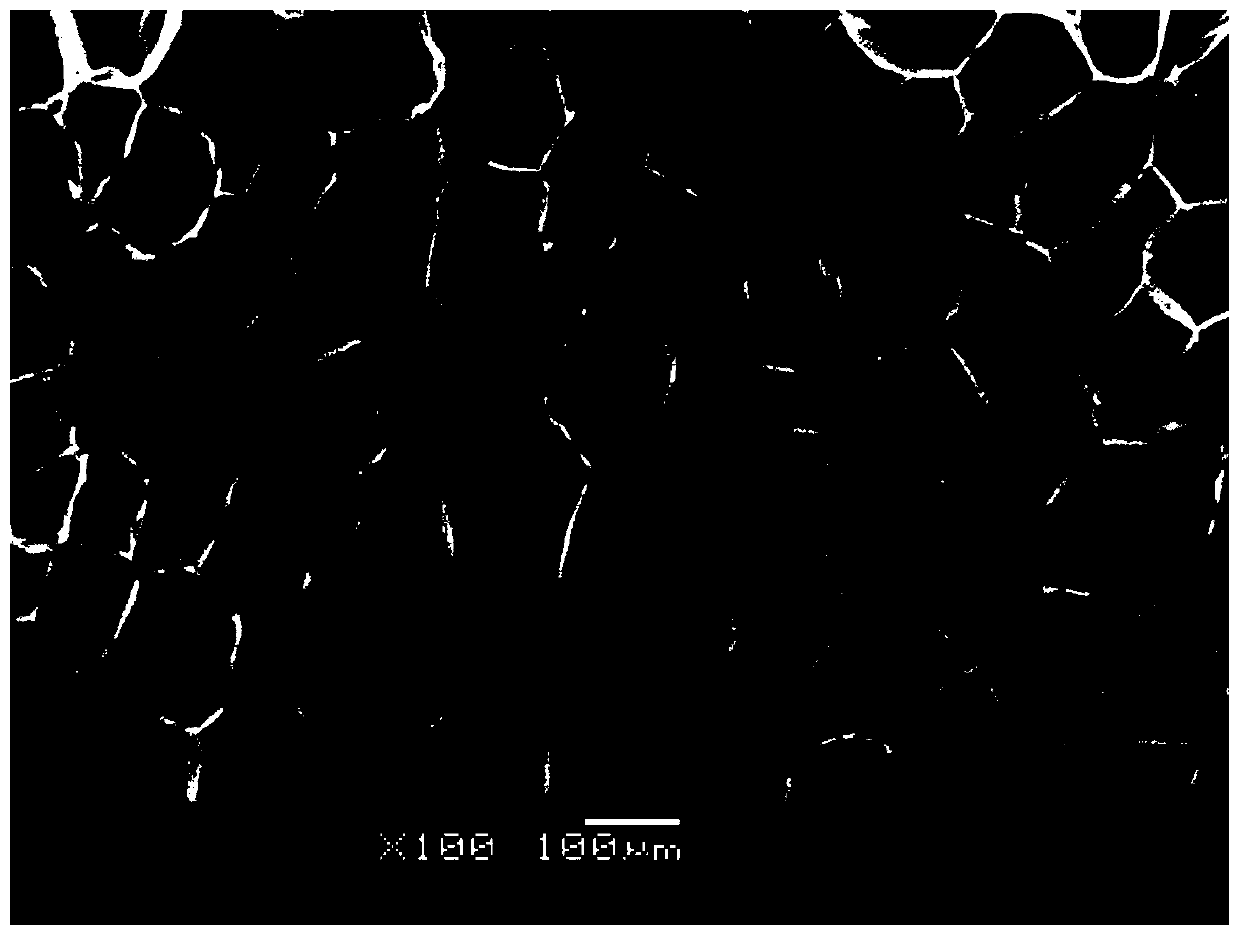

Embodiment 1

[0066] The homopolypropylene raw material (T m 155°C) is placed in the cavity 4, and the cavity 4 is heated by programmed temperature control at a heating rate of 10°C / min, heated to a foaming temperature of 147°C, and kept warm; open the ball valve 3, start the carbon dioxide injection pump 2, and control The injection pressure of carbon dioxide is 15 MPa, close the ball valve 3 and keep the pressure for 15 minutes; open the needle valve 5, slowly relieve the pressure of the cavity 4 to 10 MPa, the pressure relief rate is 0.03 MPa / s, close the needle valve 5; open the ball valve 3 and restart Inject supercritical carbon dioxide into the cavity 4 to 15MPa, close the ball valve 3, and keep the pressure for 15min; open the needle valve 5, slowly relieve the pressure of the cavity 4 to 10MPa, the pressure relief rate is 0.03MPa / s, and close the needle valve 5; Open the ball valve 3, re-inject supercritical carbon dioxide into the mold cavity 4 to 15 MPa, close the ball valve 3, and...

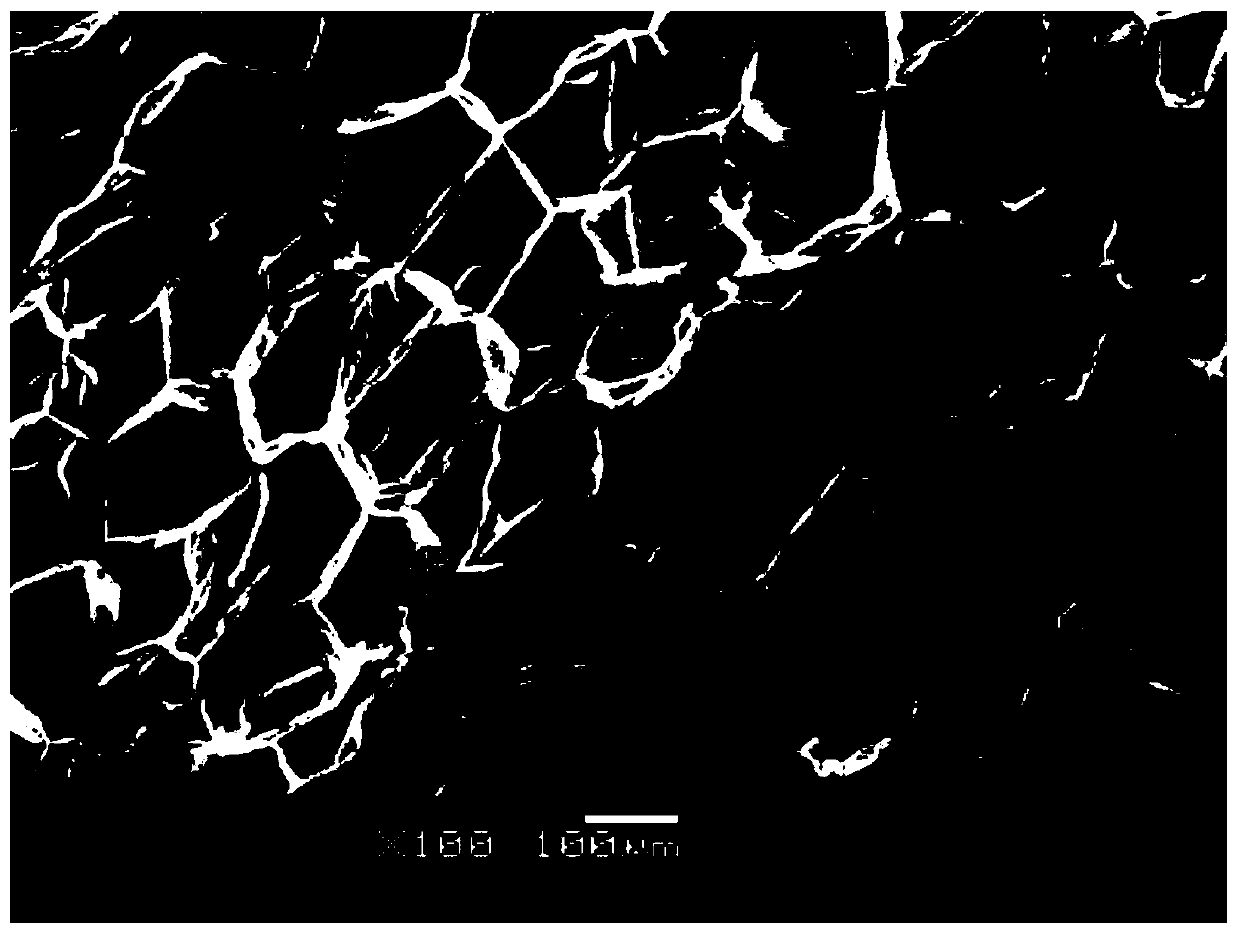

Embodiment 2

[0068] The ethylene propylene copolymer raw material (T m 155°C) is placed in the cavity 4, and the cavity 4 is heated by programmed temperature control at a heating rate of 10°C / min, heated to a foaming temperature of 147°C, and kept warm; open the ball valve 3, start the carbon dioxide injection pump 2, and control The carbon dioxide injection pressure is 15MPa, close the ball valve 3, and keep the pressure for 25min; open the needle valve 5, slowly relieve the pressure of the cavity 4 to 10MPa, the pressure relief rate is 0.03MPa / s, close the needle valve 5; open the ball valve 3, and restart Inject supercritical carbon dioxide into the mold cavity 4 to 15 MPa, close the ball valve 3, and maintain the pressure for 25 minutes; open the ball valve 6 and perform rapid pressure relief on the mold cavity 4 at a pressure relief rate of 400 MPa / s to obtain a polypropylene microcellular foam material.

Embodiment 3

[0070] The ethylene propylene butene copolymer raw material (T m 155°C) is placed in the cavity 4, and the cavity 4 is heated by programmed temperature control at a heating rate of 10°C / min, heated to a foaming temperature of 135°C, and kept warm; open the ball valve 3, start the carbon dioxide injection pump 2, and control The injection pressure of carbon dioxide is 15MPa, close the ball valve 3 and keep the pressure for 15min; open the needle valve 5, slowly relieve the pressure of the cavity 4 to 0MPa, and the pressure relief rate is 0.1MPa / s, close the needle valve 5; open the ball valve 3, and restart Inject supercritical carbon dioxide into the cavity 4 to 15MPa, close the ball valve 3 and keep the pressure for 15min; open the needle valve 5, slowly relieve the pressure of the cavity 4 to 0MPa, the pressure relief rate is 0.1MPa / s, and close the needle valve 5; Open the ball valve 3, re-inject supercritical carbon dioxide into the mold cavity 4 to 15 MPa, close the ball va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com