Municipal sludge fermentation aid

A fermentation aid, municipal sludge technology, applied in sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of low survival of beneficial microorganisms, limited utilization of sludge resources, and insufficient attention. Achieve the effect of enhancing the water solubility of phosphorus, shortening the composting reaction time, reducing shear stress and rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

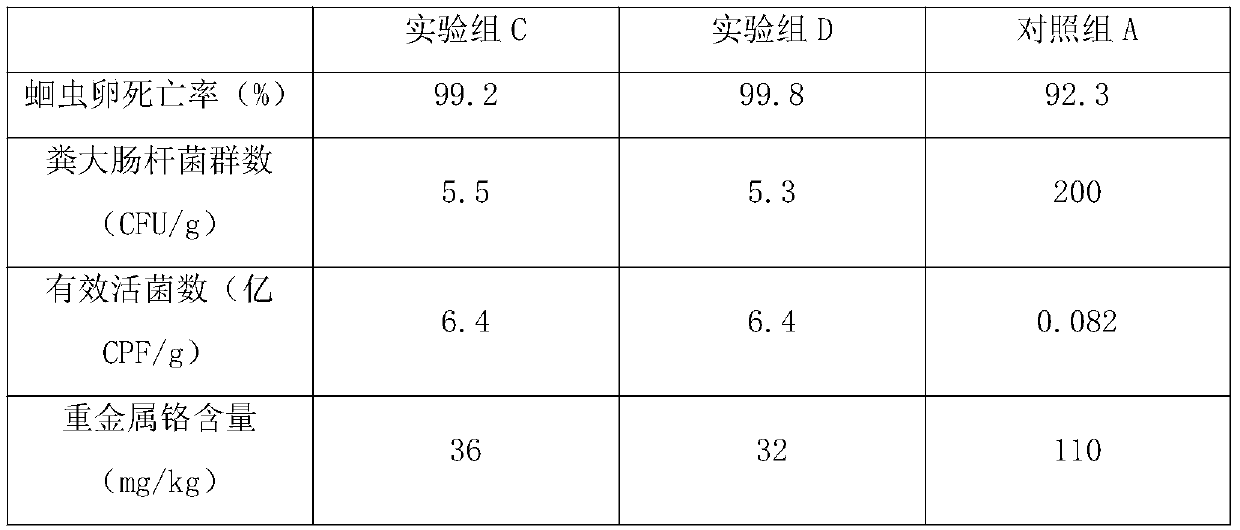

Examples

Embodiment 1

[0025] A municipal sludge fermentation aid, the fermentation aid is composed of the following raw materials in parts by weight:

[0026] Fly ash (200 mesh) 30g, chitosan derivative 90g, aluminum sulfate 30g, biological enzyme 30g, ferric chloride 30g and fermented product 90g.

[0027] The fermented product includes 36g of sucrose, 36g of biomass and 18g of sodium nitrate.

[0028] Biomass is 0.300mm particle size obtained by air-drying and grinding peanut shells and rice stalks.

[0029] A method for using municipal sludge fermentation aids, adding 300 g of fermentation aids to 10 kg of sludge to be treated, stirring for 15 minutes, as experimental group A.

Embodiment 2

[0031] A municipal sludge fermentation aid, the fermentation aid is composed of the following raw materials in parts by weight:

[0032] 60g of fly ash (200 mesh), 60g of chitosan derivatives, 45g of aluminum sulfate, 30g of biological enzymes, 45g of ferric chloride and 60g of fermented products.

[0033] The fermented product includes 12g of sucrose, 36g of biomass and 12g of sodium nitrate.

[0034] Biomass is 0.300mm particle size obtained by air-drying and grinding peanut shells and rice stalks.

[0035] A method for using municipal sludge fermentation aids, adding 300 g of fermentation aids to 10 kg of sludge to be treated, stirring for 15 minutes, as experimental group B.

Embodiment 3

[0037] A municipal sludge fermentation aid, the fermentation aid is composed of the following raw materials in parts by weight:

[0038] Fly ash (200 mesh) 30g, chitosan derivative 90g, aluminum sulfate 30g, biological enzyme 30g, ferric chloride 30g and fermented bacteria fermentation 90g.

[0039] The fermentation product that becomes 32g of sucrose, biomass 24g, sodium nitrate 16g according to the weight part array is carried out stirring and sterilizing, then the fermentation product is put into the fermenter, and then the anaerobic fermentation bacterium 10g (methanophilic fermenter) with potato starch as carrier Thermomicrococcus 13×10 9 CFU / g, Lactobacillus plantarum 9×10 9 CFU / g) into the fermenter, adjust the temperature of the fermenter to 80°C, the stirring speed is 5rpm, and start fermentation. When the pH of the fermented product is lower than 6.5, nitrogen gas is introduced to keep the pH of the fermented product at 7± 0.5, 1 day of fermentation to complete the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com