Combined water treatment method for mine-type coal preparation plant and mine water

A technology for coal preparation plant and mine water, applied in the field of water treatment, can solve problems such as affecting the stable operation of coal preparation equipment and coal preparation efficiency in coal preparation plants, inability to remove water from the system, and increasing pond accidents, so as to ensure high efficiency and stability Operation, reducing environmental pollution accidents, and avoiding the effect of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

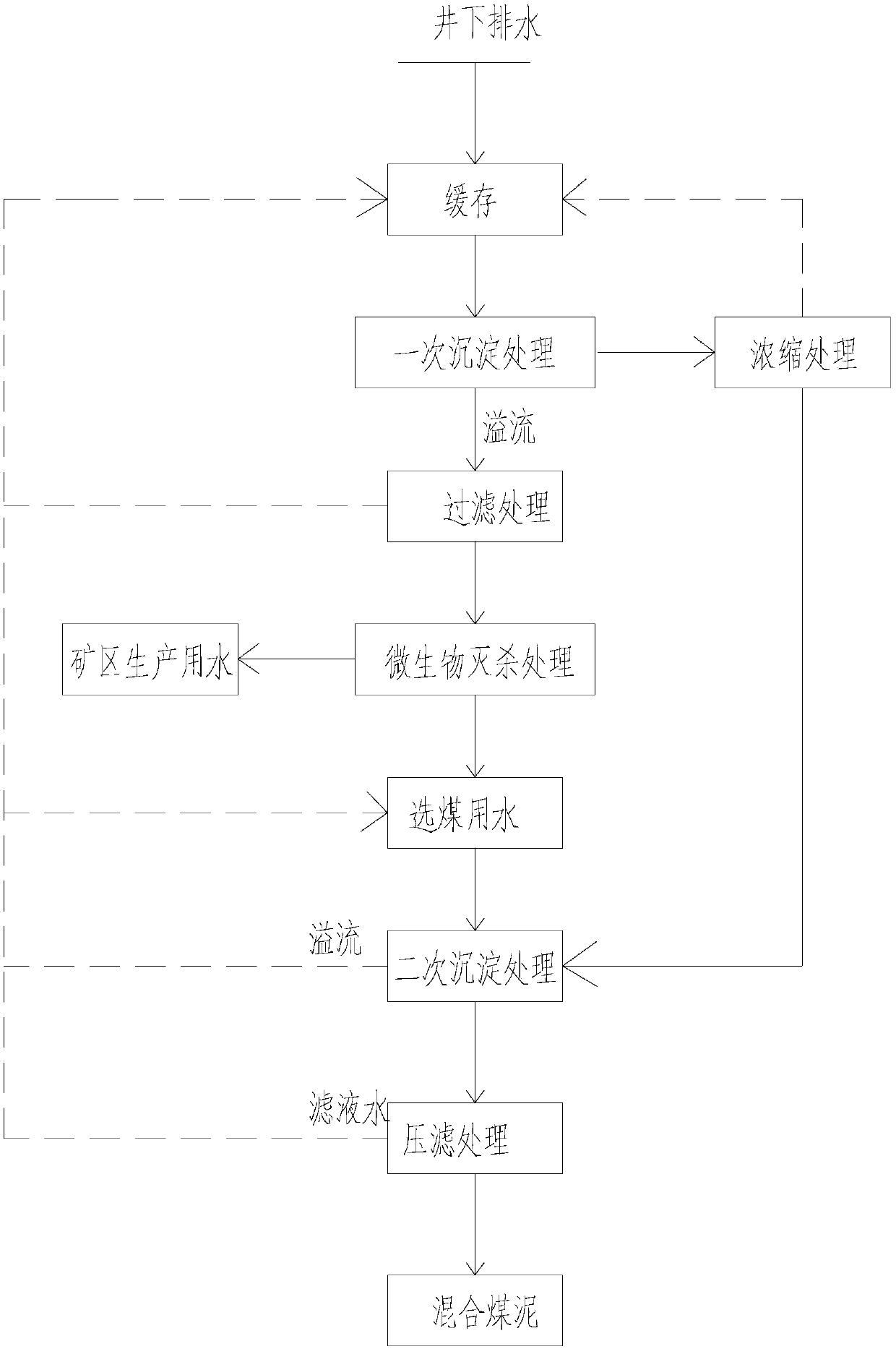

[0029] Embodiment 1: as figure 1 Shown, mine type coal preparation plant and mine water joint water treatment method, it comprises the following steps,

[0030] Step 1, cache the underground mine sludge water;

[0031] Step 2, the mine sludge water buffered in the step 1 is subjected to sedimentation treatment; the sediment overflow water generated by the sedimentation treatment is subjected to purification treatment, and the purification treatment includes sequential filtration treatment and microbial killing treatment; wherein the filtration The filtered sewage produced by the treatment is buffered together with the mine sludge water in the step 1; the industrial purified water produced after the microbial killing treatment is used for production water in mining areas, and as a backup water source for the coal preparation water; Carrying out the initial concentration treatment of the sediment bottom flow water produced by the precipitation treatment;

[0032] Step 3, buffe...

Embodiment 2

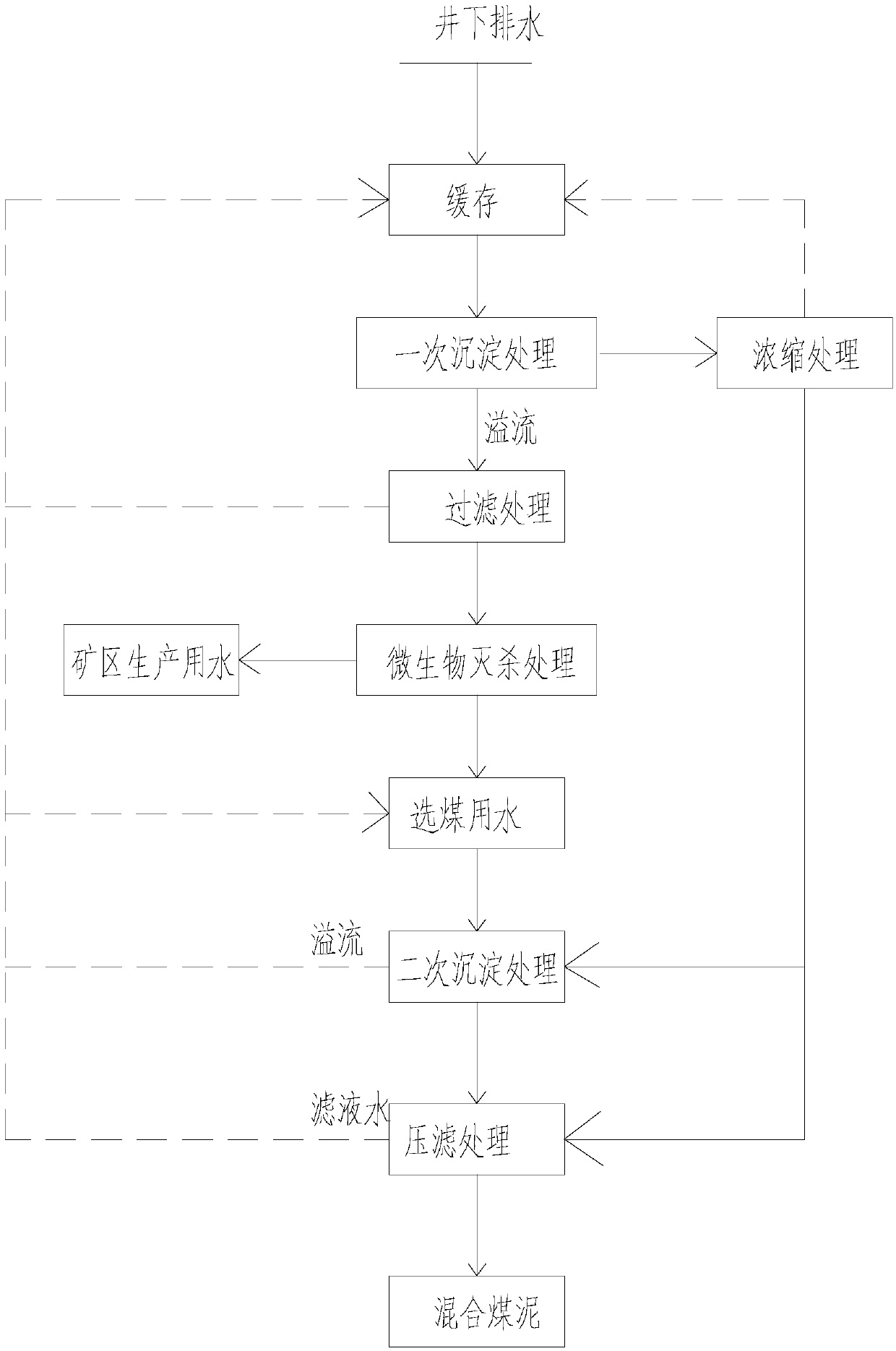

[0040] Embodiment 2: as figure 2 Shown, mine type coal preparation plant and mine water joint water treatment method, it comprises the following steps,

[0041] Step 1, cache the underground mine sludge water;

[0042] Step 2, the mine sludge water buffered in the step 1 is subjected to sedimentation treatment; the sediment overflow water generated by the sedimentation treatment is subjected to purification treatment, and the purification treatment includes sequential filtration treatment and microbial killing treatment; wherein the filtration The filtered sewage produced by the treatment is buffered together with the mine sludge water in the step 1; the industrial purified water produced after the microbial killing treatment is used for production water in mining areas, and as a backup water source for the coal preparation water; Carrying out the initial concentration treatment of the sediment bottom flow water produced by the precipitation treatment;

[0043] Step 3, buff...

Embodiment 3

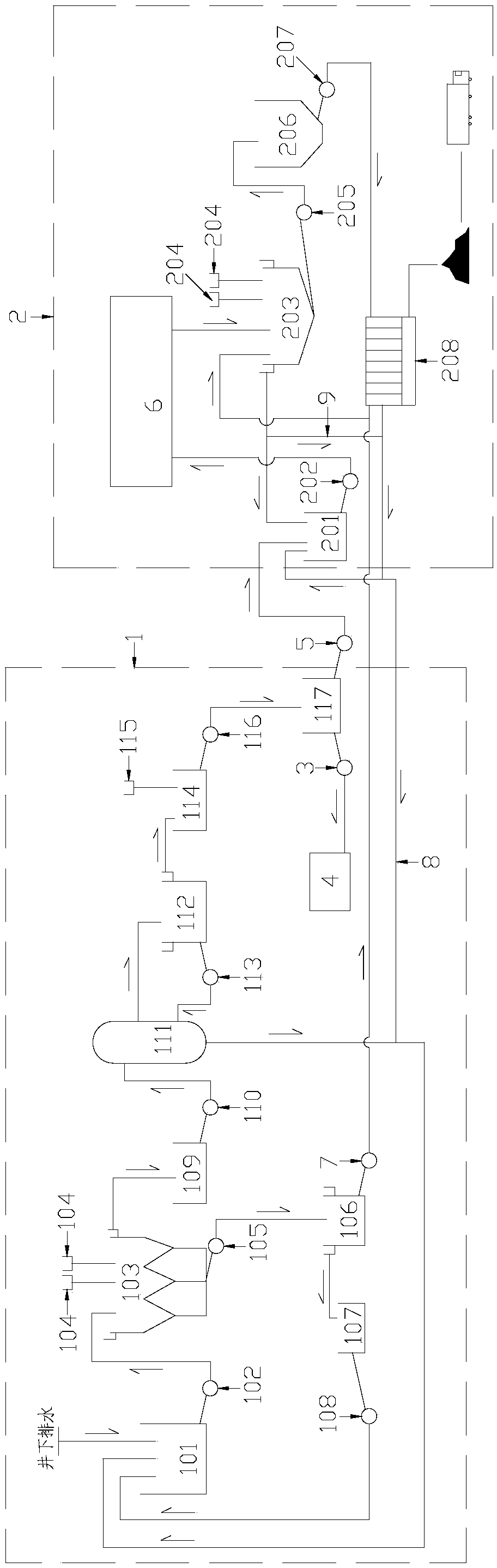

[0051] Embodiment 3: as image 3 As shown, the mine-type coal preparation plant and mine water combined water treatment system includes a mine water treatment system 1 and a coal preparation water treatment system 2; the mine water treatment system 1 includes a regulating tank 101, a regulating lift pump 102, and a sludge sedimentation tank 103, two sludge agent pools 104, sedimentation lift pump 105, sludge thickening tank 106, sump 107, water collection lift pump 108, intermediate pool 109, intermediate water lift pump 110, filter 111, backwash pool 112, Backwash water lifting pump 113, contact disinfection tank 114, hypochlorous acid generator 115, disinfection lifting pump 116 and purification pool 117; the water outlet of regulating tank 101 is communicated with sludge settling tank 103 through pipeline by adjusting lifting pump 102, Adjust the lifting pump 102 to pump the sludge water buffered in the regulating tank 101 into the sludge settling tank 103 for sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com