Electric flocculation reactor and application thereof

A technology of electrocoagulation and reactor, which is applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc. It can solve the difficulties of desulfurization wastewater treatment, metal ion pollution, unstable effluent quality, etc. problems, achieve the effect of reducing the frequency of anode replacement and plate passivation, stable effluent quality, and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

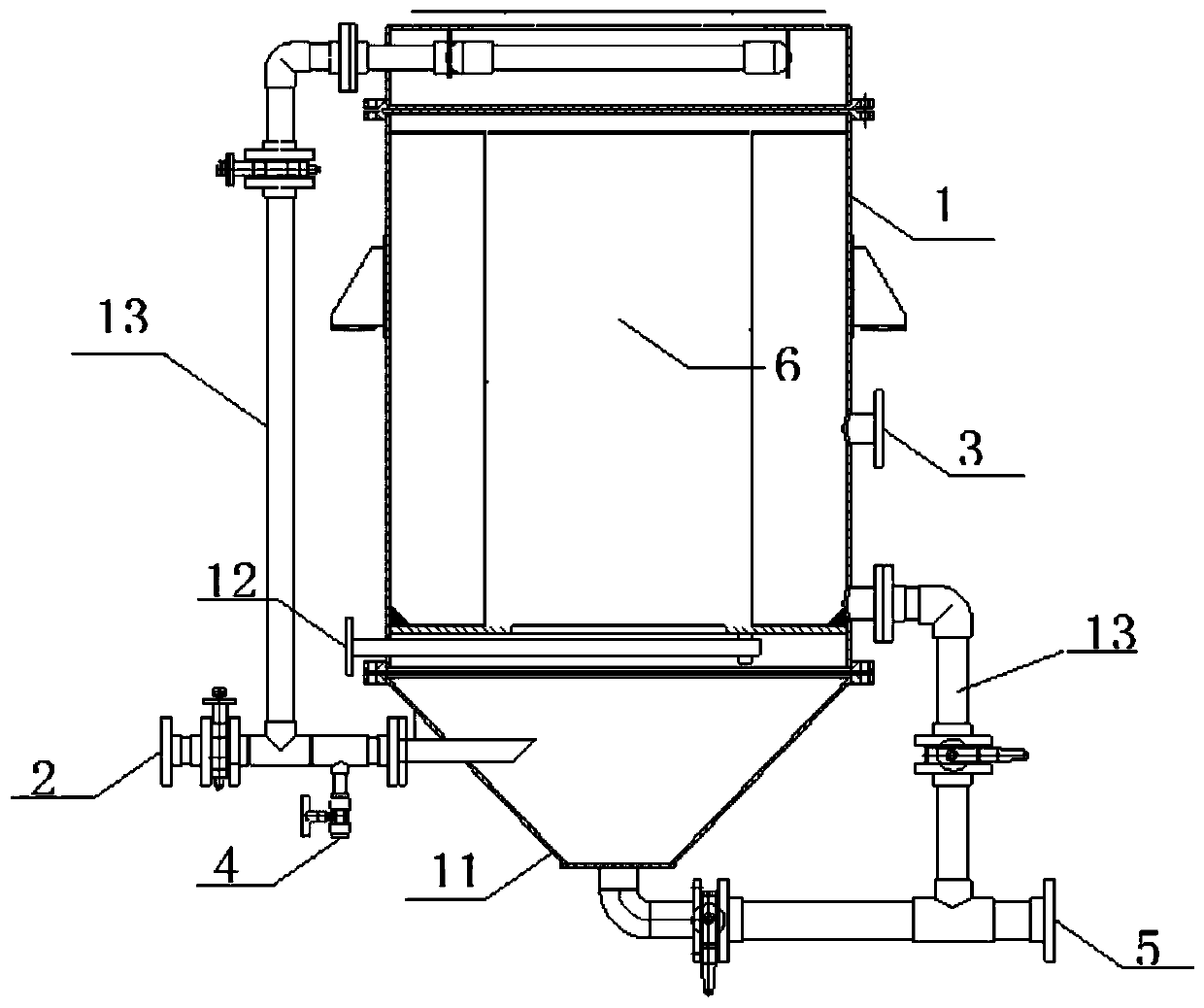

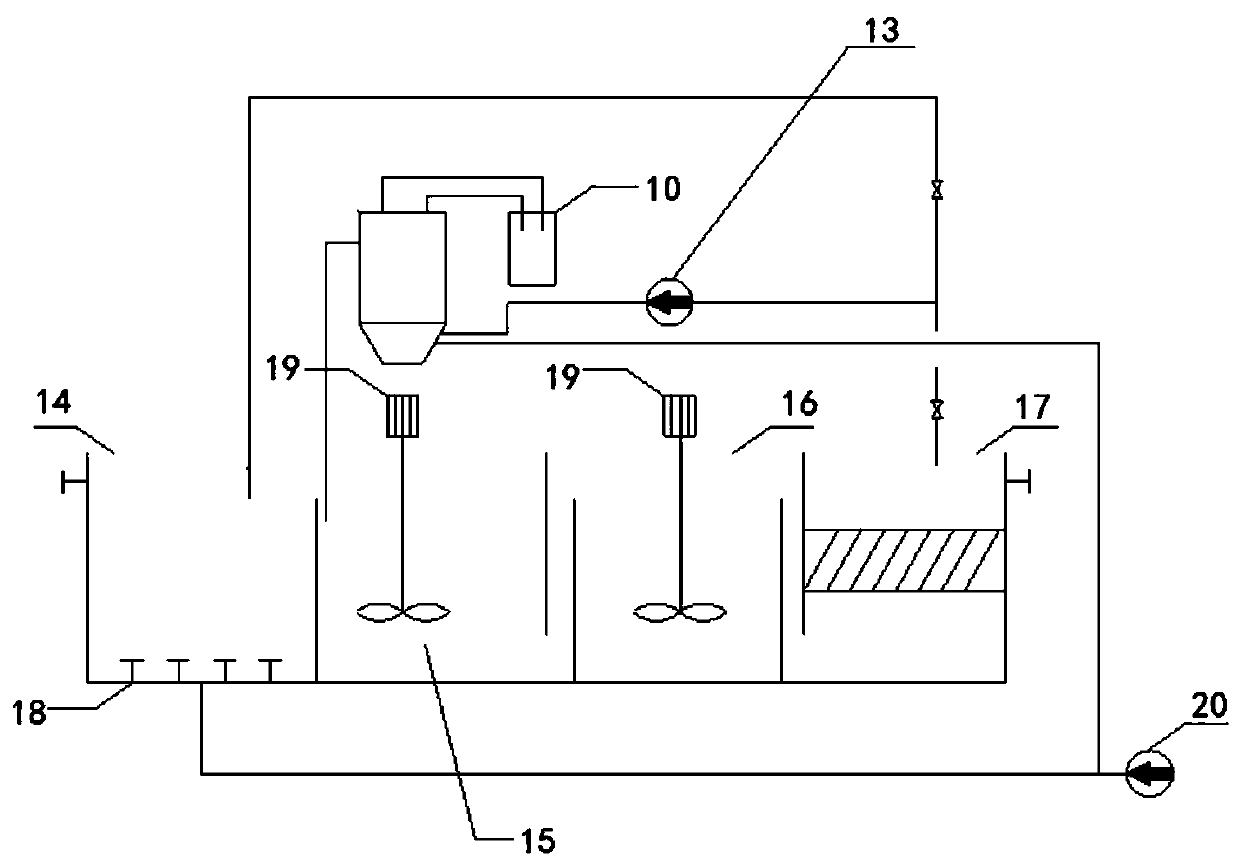

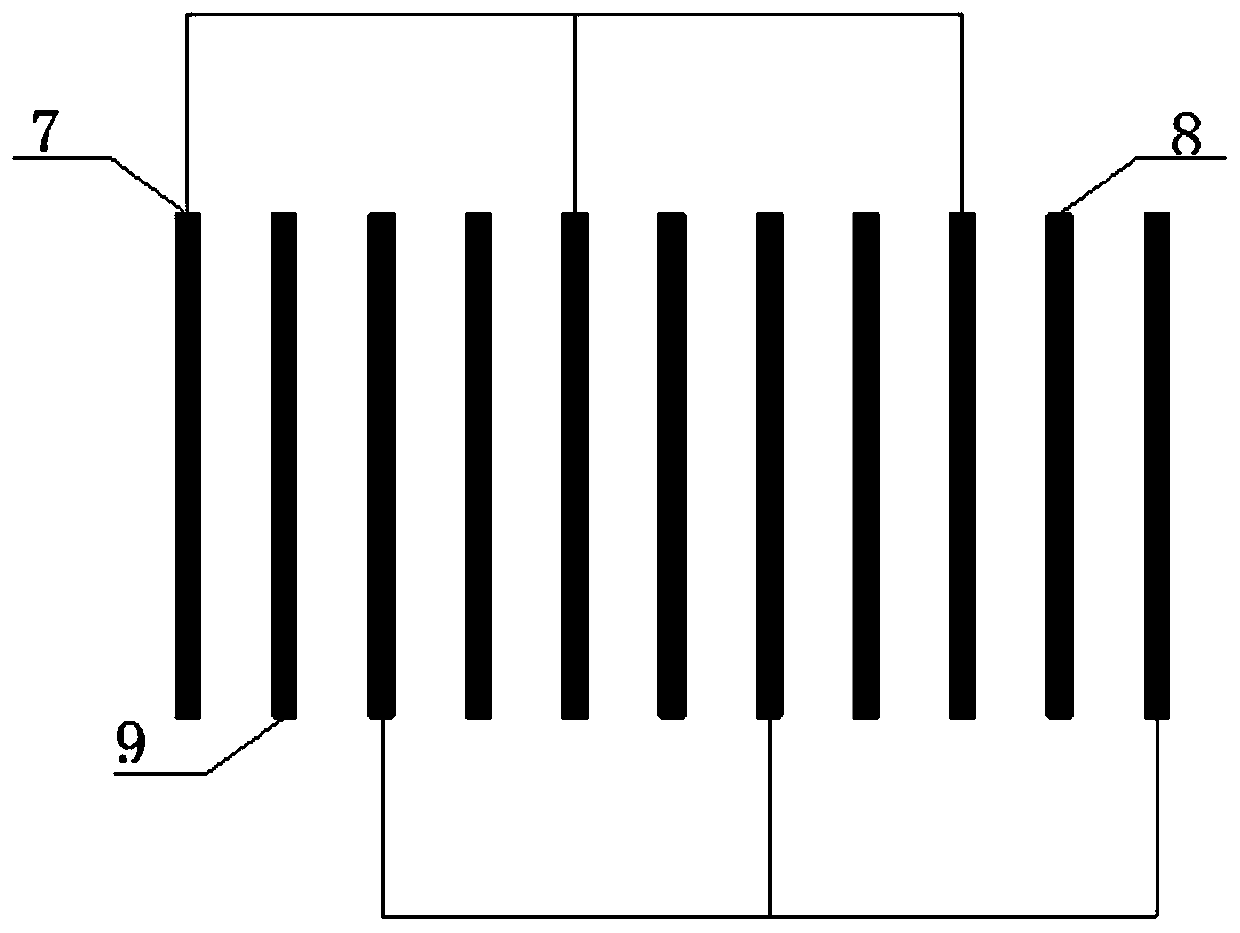

[0042] A kind of electrocoagulation reactor, with reference to Figure 1-4 , including an insulating shell 1, a water inlet 2, a water outlet 3, a cleaning system 4 and a sludge discharge outlet 5; the inside of the insulating shell 1 is provided with an electrode groove 6, and the electrode groove 6 is used to install the first electrode 7 and the second electrode 8 and the induction electrode 9, and is equipped with a power board to connect with the high-frequency pulse power supply 10; the bottom of the insulating shell 1 is provided with a mud bucket 11; one side of the insulating shell 1 is provided with an air inlet 12, and one end of the air inlet 12 It is connected with the electrode tank 6, and the other end of the air inlet 12 is connected with the outlet of the aeration fan 20 for aeration; the water inlet 2 is respectively connected with the electrode tank 6 and the mud bucket 11 through the circulation pump 13, and the water outlet 3 is located at The side of the ...

Embodiment 2

[0057] A kind of electrocoagulation reactor, with reference to Figure 1-4 , including an insulating shell 1, a water inlet 2, a water outlet 3, a cleaning system 4 and a sludge discharge outlet 5; the inside of the insulating shell 1 is provided with an electrode groove 6, and the electrode groove 6 is used to install the first electrode 7 and the second electrode 8 and the induction electrode 9, and is equipped with a power board to connect with the high-frequency pulse power supply 10; the bottom of the insulating shell 1 is provided with a mud bucket 11; one side of the insulating shell 1 is provided with an air inlet 12, and one end of the air inlet 12 It is connected with the electrode tank 6, and the other end of the air inlet 12 is connected with the outlet of the aeration fan 20 for aeration; the water inlet 2 is respectively connected with the electrode tank 6 and the mud bucket 11 through the circulation pump 13, and the water outlet 3 is located at The side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com