Composite material and preparation method thereof and electronic product with same

A technology of composite materials and electronic products, applied in the field of foldable composite materials, can solve the problems of thin and light design requirements, affecting the service life of electronic products, and limited number of times the rotating shaft can be folded, so as to save the space ratio, improve the plane effect, Improve the effect of pressing and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below in conjunction with specific embodiment:

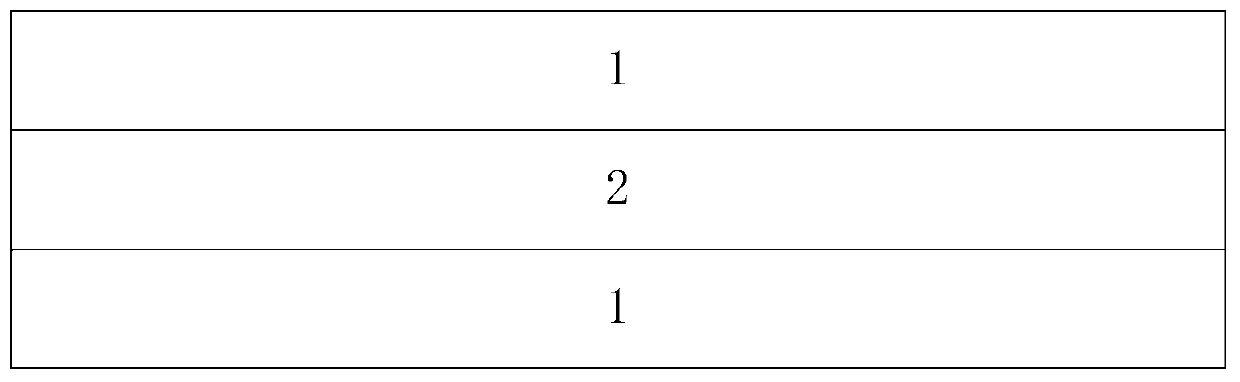

[0028] Such as figure 1 As shown, a composite material includes a flexible base layer 2 and metal layers 1 arranged on both sides of the flexible base layer 2, the thickness of the flexible base layer 2 is 0.01-0.03mm, and the thickness of the metal layer 1 It is 0.05-0.08mm.

[0029] Further, the flexible base layer 2 and the metal layer 1 are integrally formed through a bonding stamping process or a hot-melt process.

[0030] Further, the flexible base layer 2 is a silicone layer.

[0031] Further, the metal layer 1 is an aluminum layer or a copper layer or a stainless steel layer.

[0032] When the metal layer is a stainless steel layer, the composition of the stainless steel is as follows:

[0033] Element mass percentage nickel 1.2~5.0 chromium 12~20 manganese 9~17 silicon ≤0.5 carbon ≤0.20 nitrogen ≤0.20 phosphorus ≤0.045 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com