Aluminium foil cigarette packing device for cigarette packing unit

A technology of cigarettes and aluminum foil, which is applied in the packaging of cigarettes, etc., and can solve problems such as rotten aluminum paper, affecting the operation efficiency of packaging units, and incomplete folding of aluminum foil paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

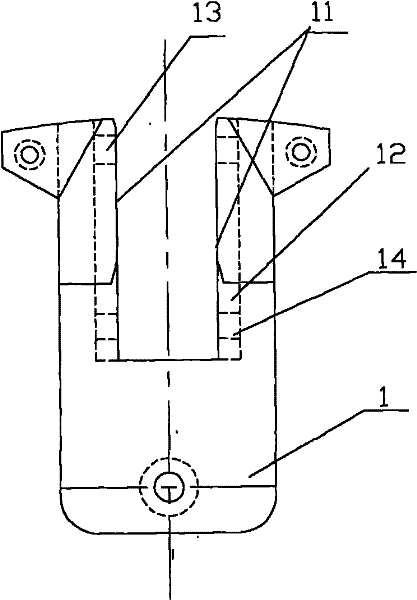

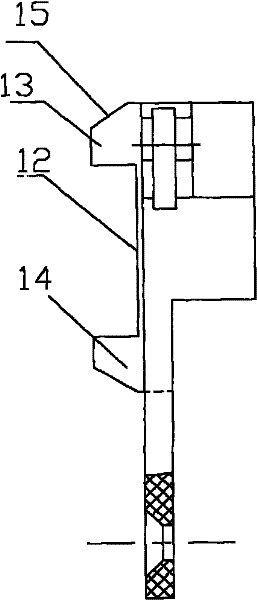

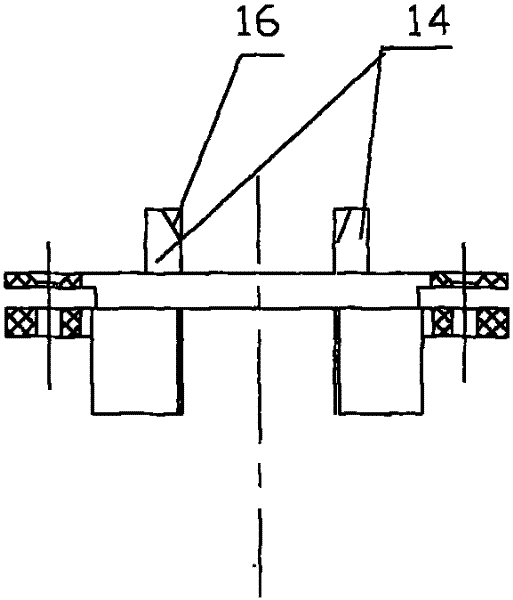

[0025] Such as figure 1 , figure 2 and image 3 As shown, the outer edge of the working surface 11 of the box mold 1 is symmetrically provided with a boss 12 whose length is equivalent to the length of the end wall of the cigarette pack, and one side of the boss 12 extends outwards along the working surface 11 of the box mold; the boss 12 includes A first additional boss 13 and a second additional boss 14 are respectively arranged at both ends of the outer edge of the working surface of the box mold. The first additional boss 13 and the second additional boss 14 are respectively as close as possible to the working position of the box mold 1 for folding the corners of the cigarette packets. In order to reduce the interference caused by the bosses on the edge of the box mold to other matching parts during the rotation of the packaging wheel, an inclined surface 15 can be provided on the outside of the first additional boss 13 and the second additional boss 14, wherein the sec...

Embodiment 2

[0029] Such as Figure 8 , Figure 9 and Figure 10 As shown, the outer edge of the working surface 11 of the box mold 1 is symmetrically provided with a boss 12 whose length is equivalent to the length of the end wall of the cigarette pack, and one side of the boss 12 extends outwards along the working surface 11 of the box mold; the boss 12 includes respectively The first additional boss 13 and the second additional boss 14 are arranged at both ends of the outer edge of the working surface of the box mold; the second additional boss 14 is a trapezoidal stepped boss.

[0030] Same as Embodiment 1, in order to cooperate with the packaging wheel box mold with trapezoidal step boss shape, the corresponding front and rear end wall fixed folder working surfaces should also have through notches engaged with box mold bosses.

[0031] The box mold shown in this embodiment is suitable for packaging cigarette packs with composite aluminum foil paper.

Embodiment 3

[0033] In order to make the present invention applicable to cigarette packs of vacuum-coated aluminum foil paper and composite aluminum foil paper at the same time, the box molds described in Embodiment 1 and Embodiment 2 can be used in conjunction, that is, the molds described in Embodiment 1 and Embodiment 2 can be used together The box mold is set on the rear wall and the front wall of the packaging wheel; correspondingly, the end wall fixed folders described in Embodiment 1 and Embodiment 2 are respectively set as a rear end wall fixed folder and a front end wall fixed folder. Because the front wall of the cigarette pack is close to the filter tip of the packaged cigarette, it is harder than the rear wall of the cigarette pack, so a larger end wall wrapping paper is needed to make room to avoid being brought in when the corner is folded.

[0034] In the actual assembly process of the above-mentioned embodiments, the following adjustments should also be made:

[0035] One i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com