Full-automatic deep-cylinder wine box assembling machine

A fully automatic and assembly machine technology, applied in the direction of packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of increased operating costs, high defective product rate, low productivity, etc., to improve productivity, reduce operator labor, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

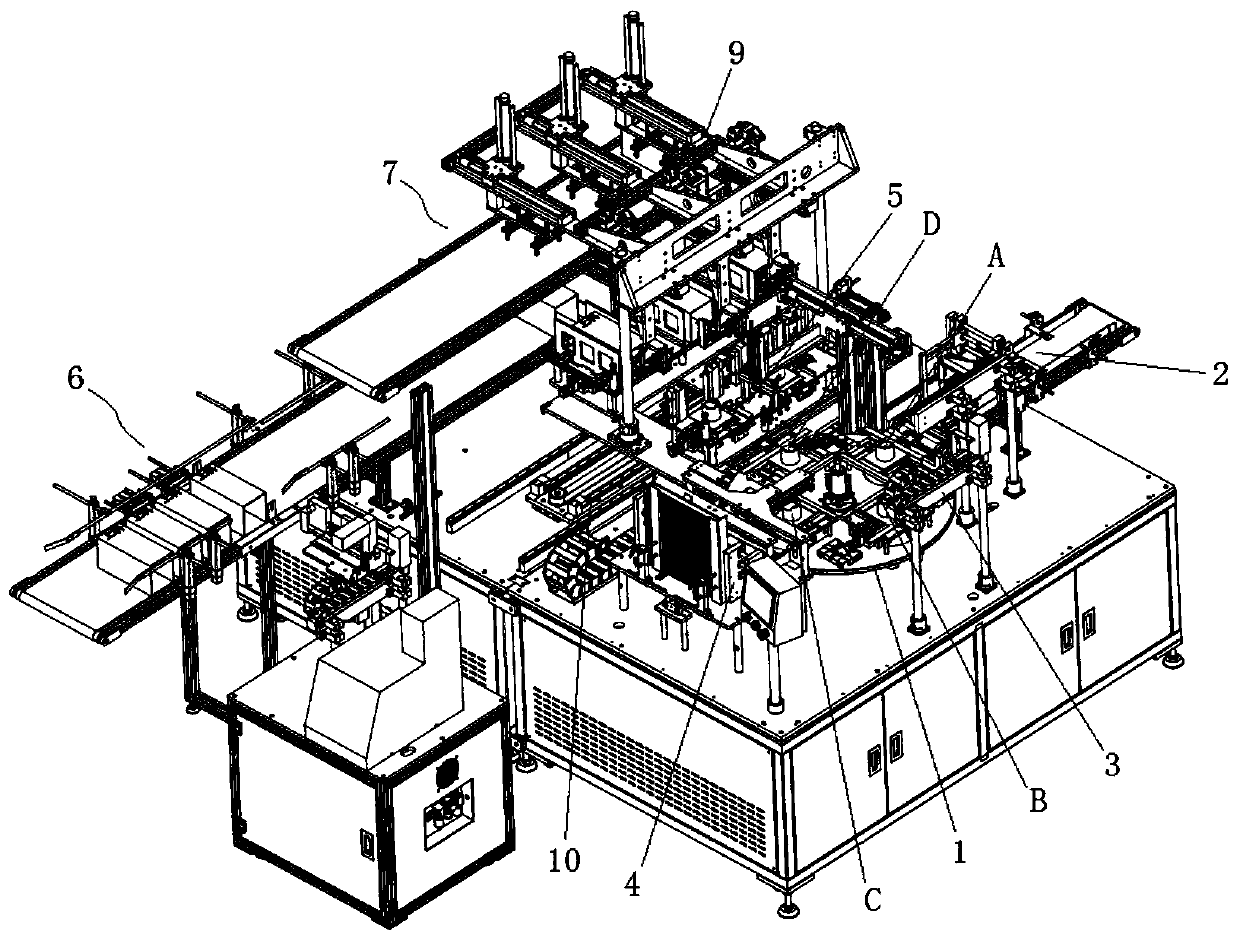

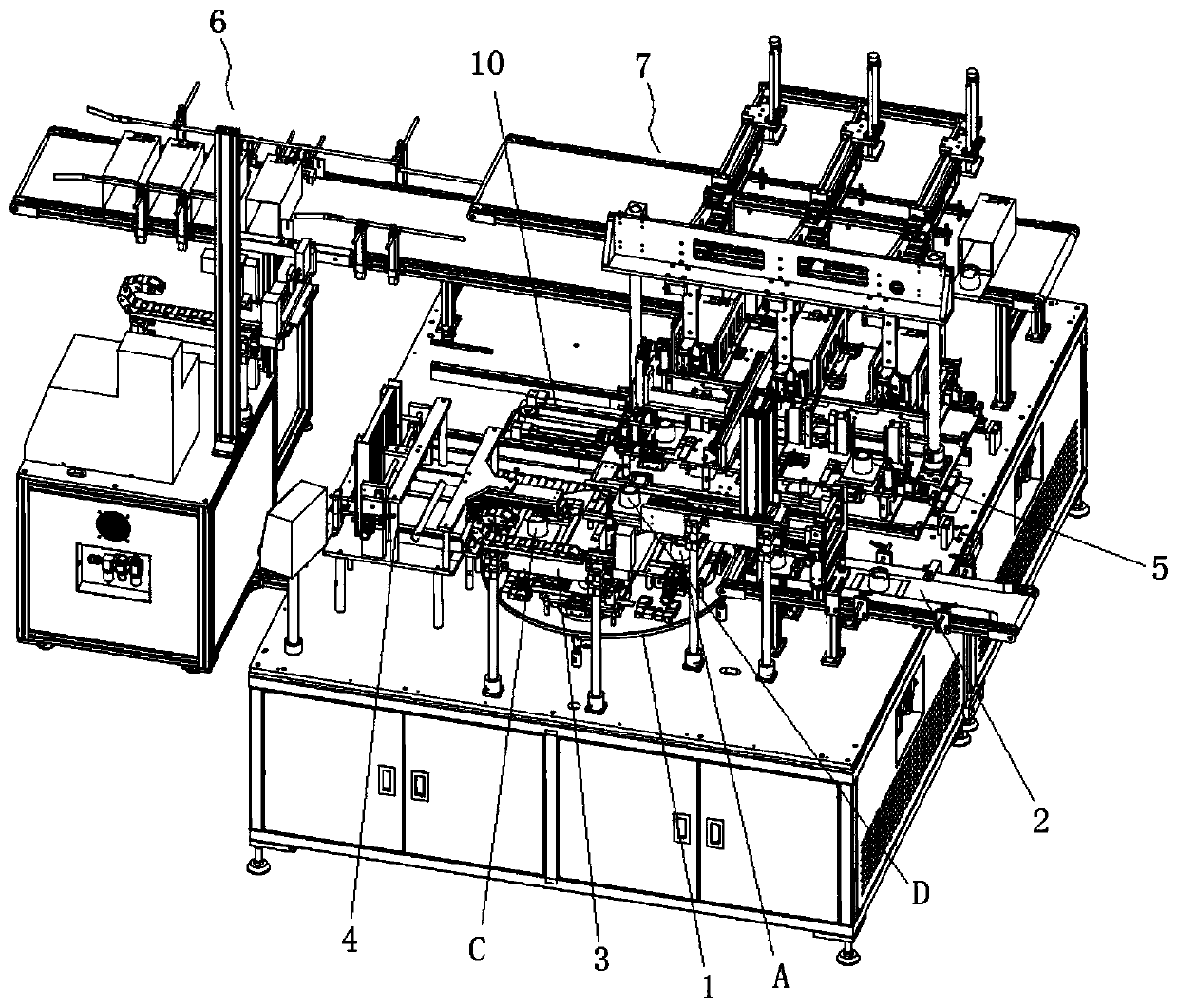

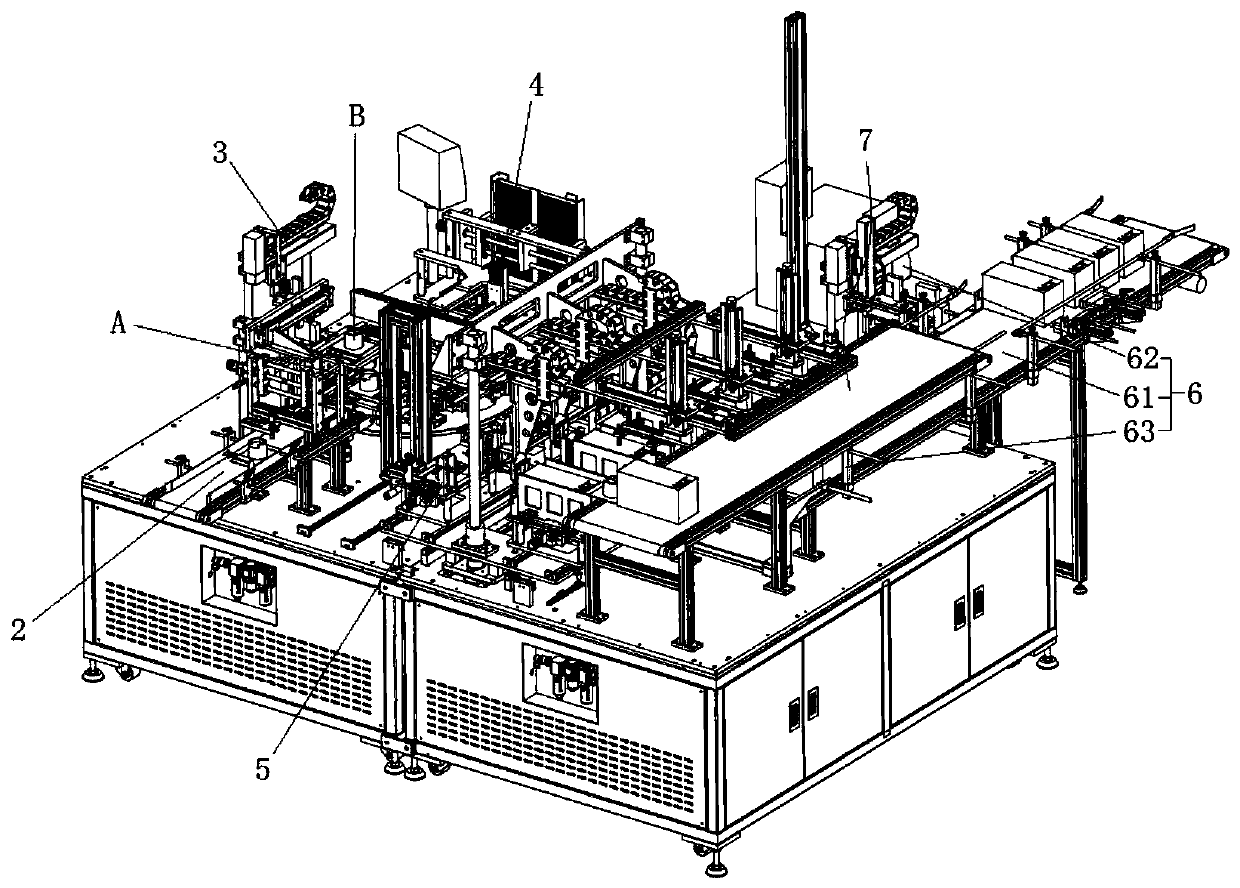

[0033] Such as figure 1 , figure 2 and image 3 As shown, a fully automatic deep-tube wine box assembly machine includes a divider device 1, an upper cover conveying device 2, a glue coating device 3, an inner wall bar assembly device 4, a wine box tube and an upper cover assembly device 5, Wine box tube conveying device 6 and output device 7; wherein, divider device 1 is erected on the machine platform, and divider device 1 is provided with four stations; Side, used to transport the upper cover to the first station A of the divider device 1; the gluing device 3 is erected on the outside of the divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com