Lamp holder insertion core

A ferrule and lamp holder technology, applied in discharge lamps, incandescent lamps, incandescent lamp parts, etc., can solve the problems of laboriousness, troublesome removal of wires, damage to lamp holders or other accessories, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

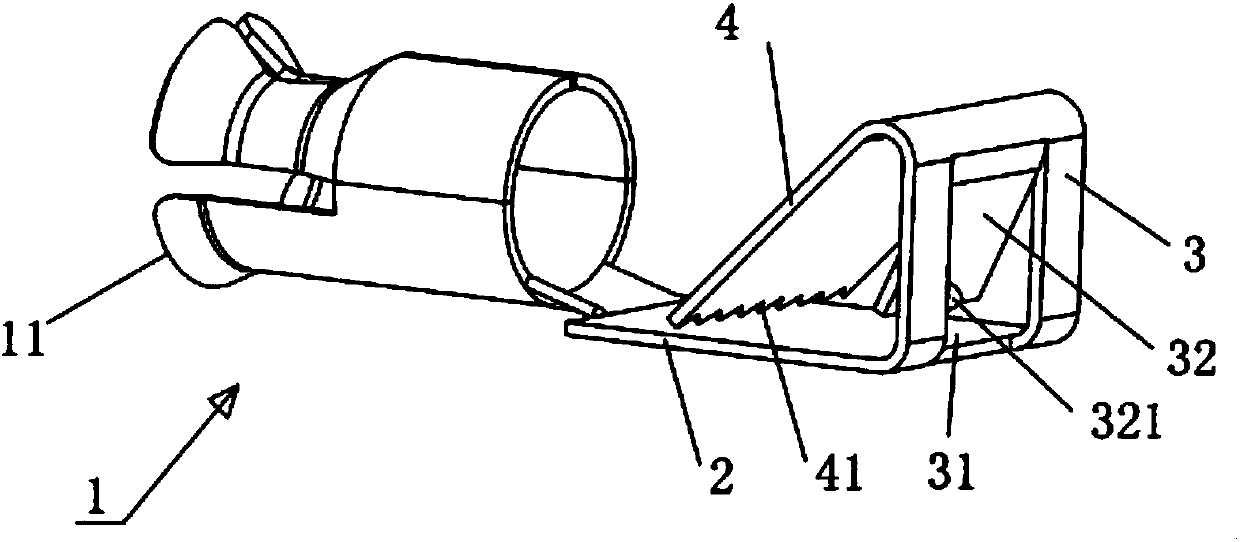

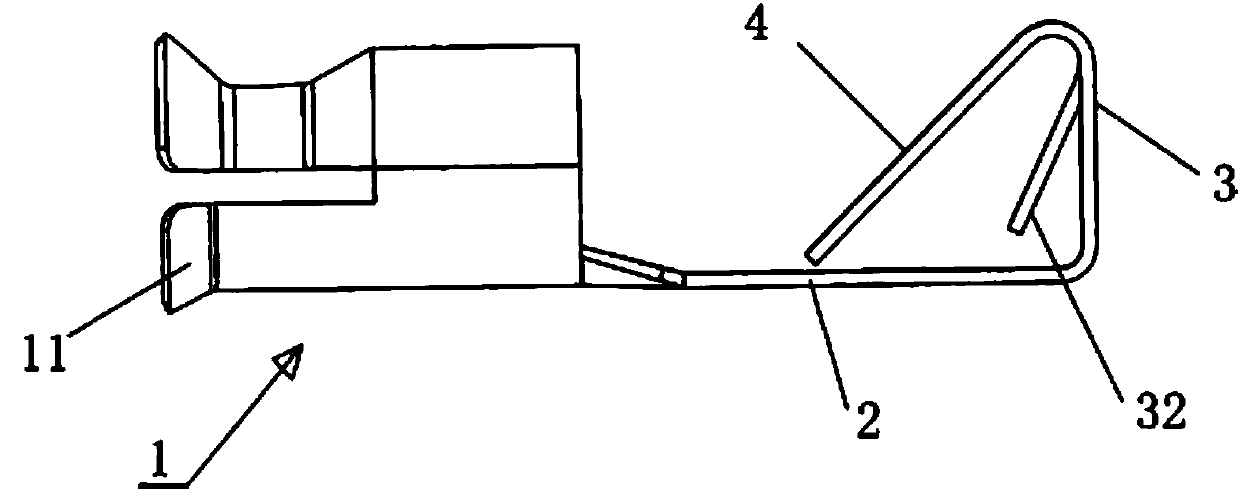

[0015] refer to figure 1 , figure 2 , a socket insert of the present invention, comprising a conductive metal sheet, one side of the metal sheet is set as a power contact piece 1 connected to the lamp tube, the power contact piece 1 can be bent into a hollow cylindrical shape, The cylindrical power contact piece 1 and the side plate 3 are arranged on the same side of the connecting plate 2, and the end of the cylindrical power contact piece 1 is provided with a number of small blades 11 that are slightly opened outwards, which is convenient for the lamp tube The plug can be inserted and pulled out more smoothly; one end of the power contact piece 1 extends outwards with a connecting plate 2, and one end of the connecting plate 2 is bent to form a side plate 3 at a certain angle with the surface of the connecting plate 2. This embodiment is set as 90°, so that the socket 31 can face the connecting port of the lamp holder and the wire, which is conducive to the smoother insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com