Zinc smelting burdening optimization method and system

An optimization method, zinc smelting technology, applied in the direction of instruments, data processing applications, forecasting, etc., can solve the problems of increased smelting cost of zinc concentrate raw materials, large fluctuations in the quality of mixed zinc concentrate, and inconformity with the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

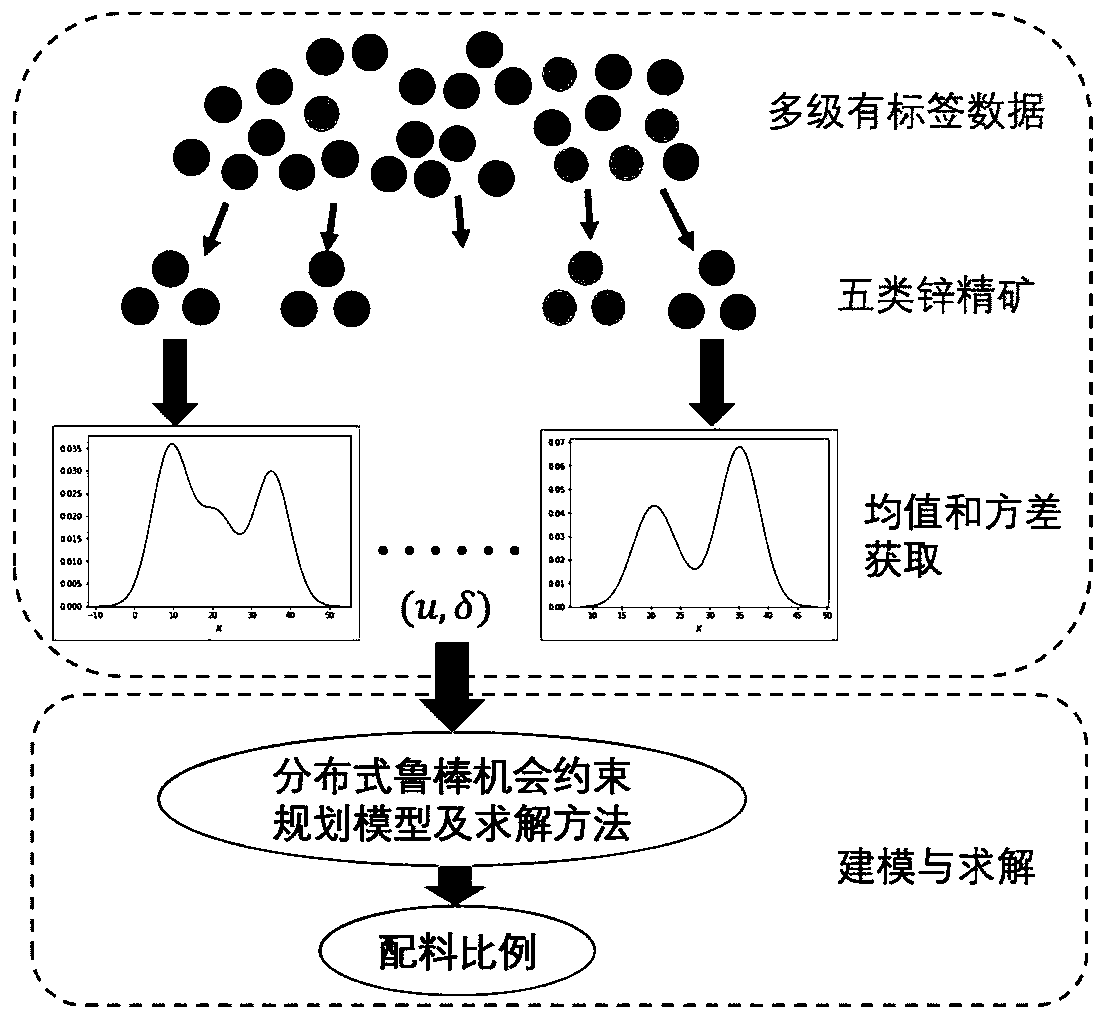

[0075] Such as figure 1 Shown, a kind of zinc-smelting batching optimization method comprises the following steps:

[0076] A method for optimizing zinc smelting ingredients, comprising the following steps:

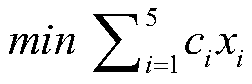

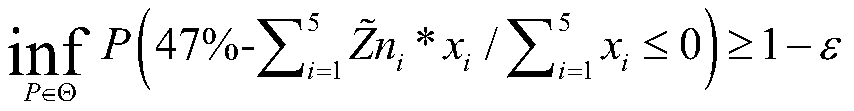

[0077] Obtain the minimum or maximum content of various mineral elements in the historical data, the upper limit of the usage of various zinc concentrates, the total amount of total zinc concentrates used, the types of zinc concentrates and their corresponding prices, and Aiming at the lowest production cost of zinc in mixed zinc concentrates, taking the usage of various zinc concentrates as decision variables, and taking the content of various mineral elements in various zinc concentrates as random variables, a distributed robust joint chance-constrained programming is constructed Model;

[0078] Obtain the mean value and variance of various mineral elements corresponding to various zinc concentrates when they are put into storage, and solve the optimal solution of the...

Embodiment 2

[0084] Embodiment 2 is an extended embodiment of Embodiment 1. The difference lies in the calculation of the second-order moment matrix of the covariance matrix of various mineral elements in various zinc concentrates, and how to construct a distributed robust joint opportunity The constraint programming model and how to solve the distributed robust joint chance constraint programming model are detailed.

[0085] in,

[0086] Calculation of the second moment matrix of the covariance matrix of various mineral elements in various zinc concentrates, including

[0087] According to the fluorescent test data of zinc concentrates in each warehouse, use statistical methods to obtain the mean and variance of each component in each warehouse

[0088] The formula for calculating the mean is as follows:

[0089]

[0090] The formula for calculating the variance is as follows:

[0091]

[0092] Since the amount and composition of zinc concentrate in each mine is changing dynamica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com