Cement concrete batching plant backfield intelligent monitoring system based on BIM platform

A technology for cement concrete and mixing plants, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as substandard concrete quality, changing proportions, cutting corners, etc., so as to improve site management level and improve management Horizontal, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

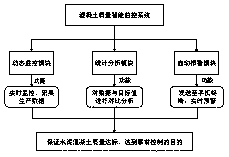

[0030] The intelligent monitoring system for the cement concrete mixing plant backyard based on the BIM platform in this embodiment is as follows: figure 1 As shown, it includes three parts: dynamic monitoring module, statistical analysis module and automatic alarm module. The dynamic monitoring module monitors and automatically collects the concrete production data of the mixing station in real time, and sends the monitoring information data to the statistical analysis module in real time through the GPRS network. The statistical analysis module compares and analyzes the concrete production data with the target value, and when the error value exceeds the allowable error range, the automatic alarm module sends relevant information to the mobile phone terminal of the quality management personnel in real time for timely warning.

[0031] The system uses the method of dynamic quality management, and adopts the Internet of Things technology combining software and hardware to effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com