New energy automobile accessory assembly analogue simulation system

A new energy vehicle and simulation system technology, applied in the application field of automobile production line, can solve the problems of easy misoperation of operators, affecting work efficiency, long time of product assembly, etc., and achieve the effect of improving work and collaboration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

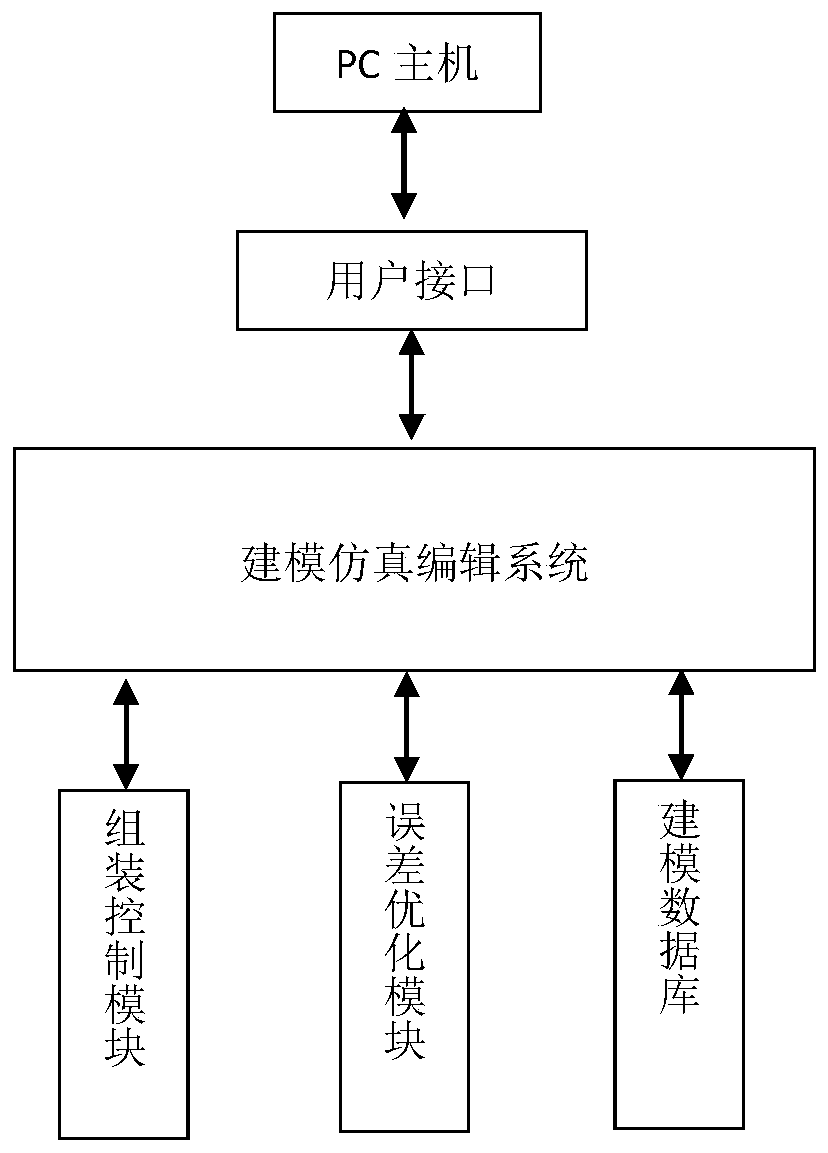

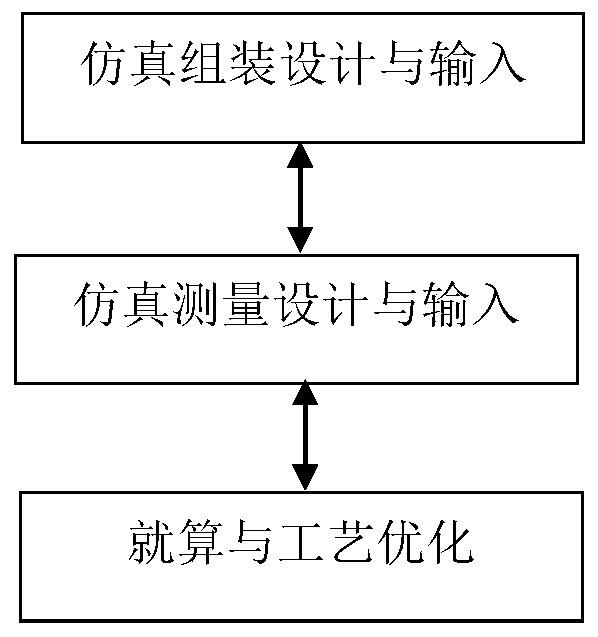

[0035] Example: such as Figure 1-3 Shown, the present invention provides technical scheme:

[0036] A new energy auto parts assembly simulation simulation system, a PC host, a user interface, a modeling simulation editing system, an assembly control system, an error optimization system and a modeling database, the PC host is connected to the modeling simulation editing system through the user interface, The modeling simulation editing system is connected with the assembly control system, the error optimization system and the modeling database.

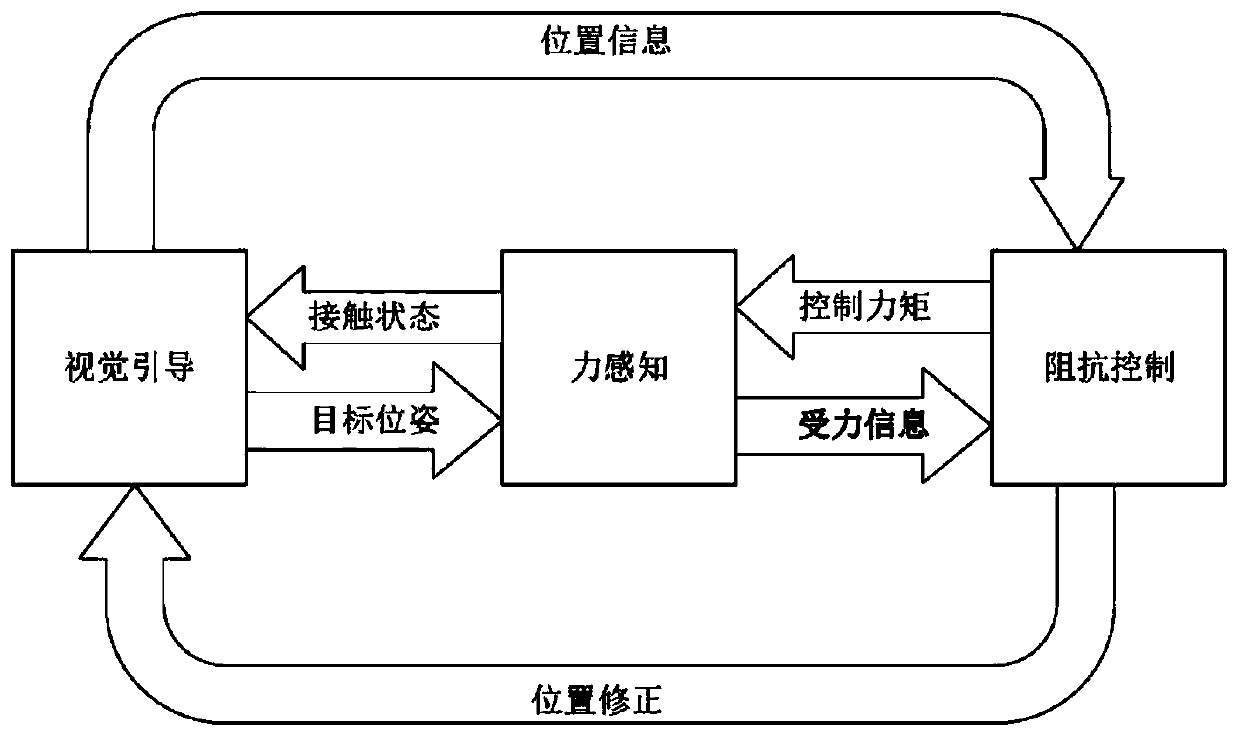

[0037] As a further improvement of this solution, the assembly control system includes:

[0038] The visual guidance module is used to collect the target pose information on the assembly workbench and the current position information of the robotic arm, and transmit them to the force perception module and the impedance control module respectively;

[0039] The force perception module is used to collect the contact information betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com