Array cylindrical group type multi-stage lamination micro-channel throttling heat exchange refrigerator

A column group and micro-channel technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of small air intake, low heat exchange efficiency, and limited space for cooling temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

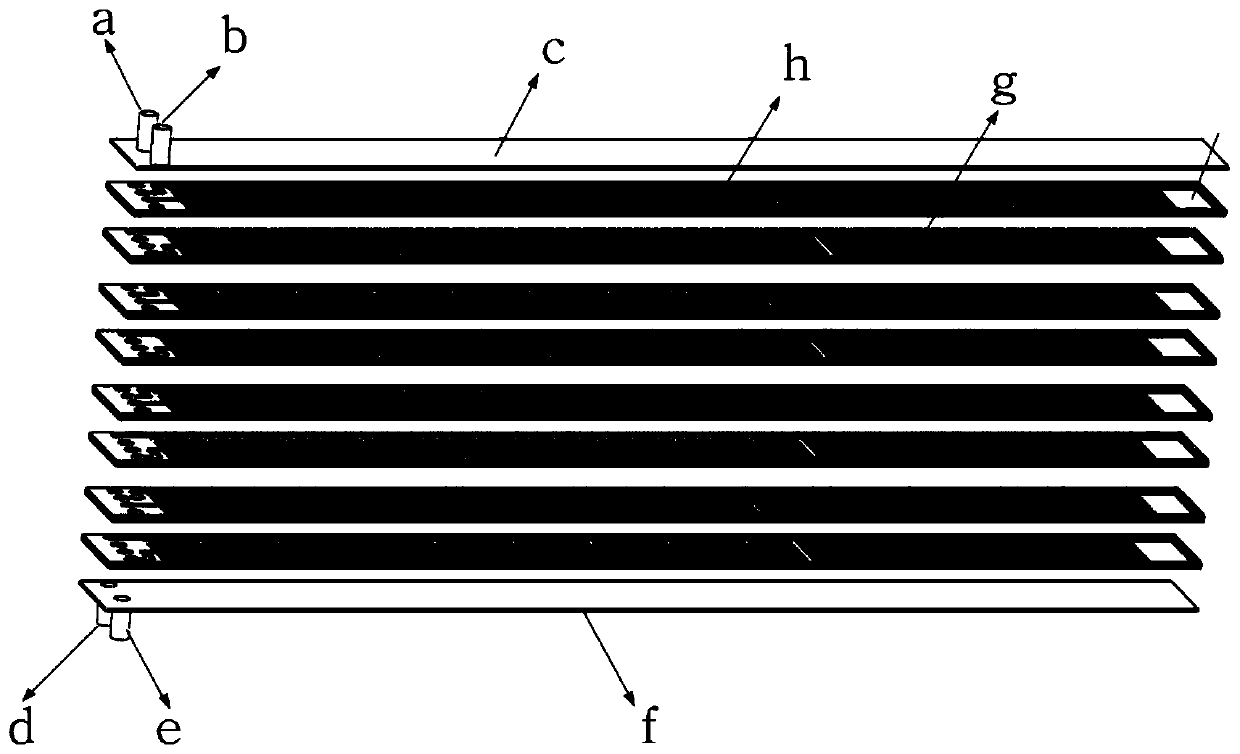

[0033] Such as figure 1 , 2 As shown, the array cylinder group multi-stage laminated microchannel throttling heat exchange refrigerator includes an upper cover plate c stacked in sequence, a plurality of upper plates h and a plurality of lower plates g stacked up and down staggered, and a lower cover Plate f, high-pressure gas inlet pipe a, low-pressure gas outlet pipe b, high-pressure gas outlet pipe d, and low-pressure gas inlet pipe e.

[0034] The upper and lower upper cover plates c and lower cover plates f with a certain thickness play a role in supporting and stabilizing the entire refrigerator.

[0035] The upper cover plate c is respectively provided with through high-pressure gas inlet holes and low-pressure gas outlet holes.

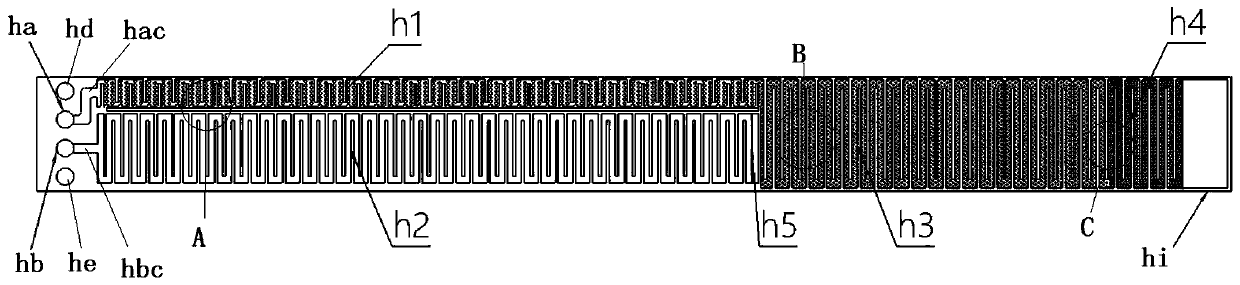

[0036] The upper plate h is rectangular, including the inlet and outlet sections, the channel section and the evaporation chamber hi.

[0037] Such as image 3 As shown, the inlet and outlet section has a high-pressure inlet hole ha, a hig...

Embodiment 2

[0085] Such as Figure 11 , Figure 12As shown, the other structure of this embodiment is the same as that of Embodiment 1, except that the flow channel h1, flow channel h3, flow channel h4, flow channel g3, and flow channel g6 in embodiment 1 are changed from S-shaped channels to straight rectangular channels. , the rectangular channel is a concave rectangular groove set on the plate, and the raised cylindrical needle rib set in the flow channel is cancelled.

[0086] When the gas passes through the flow channel h1, it will be accompanied by the Bernoulli effect and the burnt soup effect, and the Bernoulli effect is dominant at this stage, and the connection between the flow channel h1 and the flow channel h3 adopts the form shown in h8' , the high-pressure gas produces a large pressure drop here after passing through the h1 channel, forming the first throttling and cooling, and at the same time, it can be pre-cooled by the low-pressure gas after throttling by the lower plat...

Embodiment 3

[0088] Such as Figure 13 , Figure 14 As shown, the other structure of this embodiment is the same as that of Embodiment 1, except that the flow channel h1, flow channel h3, flow channel h4, flow channel g3, and flow channel g6 in Example 1 are changed from S-shaped channels to be set in channels A plurality of columns arranged in forked rows are used for throttling and support.

[0089] Function and effect of embodiment

[0090] The structural innovation of the array cylinder group type multi-stage stacked microchannel throttling heat exchange refrigerator in this embodiment is to completely isolate the high and low pressure gas from entering the refrigerator to recovering the gas, which is suitable for the mixing of high and low pressure gases Afterwards, they will influence each other on their respective properties or reaction situations; secondly, the two kinds of gases in this structure are throttled and cooled twice. The flow can generate more cold energy into the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com