Sulfur hexafluoride gas supplementing system and method

A technology of sulfur hexafluoride and gas supply system, which is applied in container filling method, container discharge method, gas/liquid distribution and storage, etc. problems, to prevent transitional shaking and transitional loosening, save lateral space, and easily adjust the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

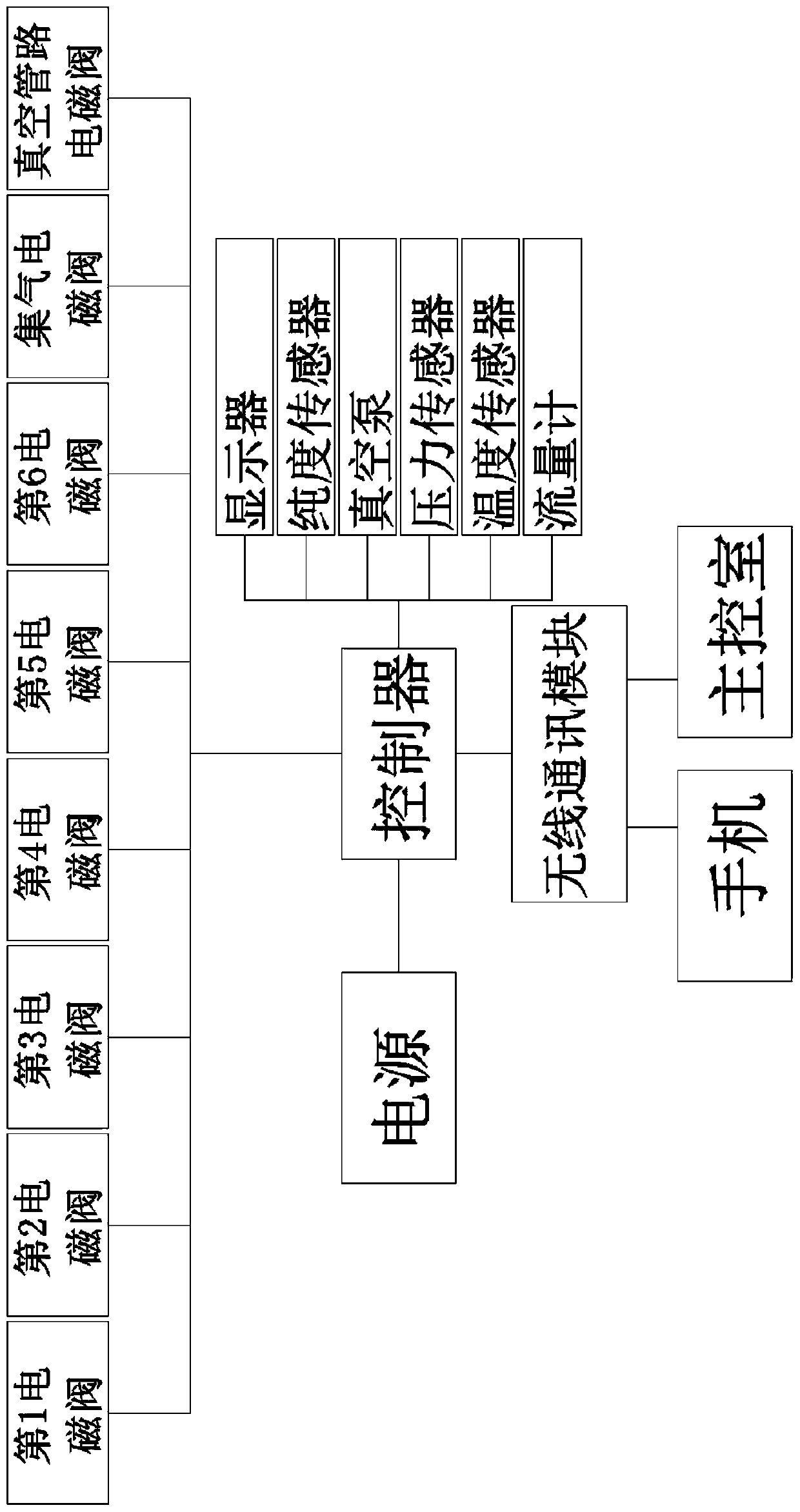

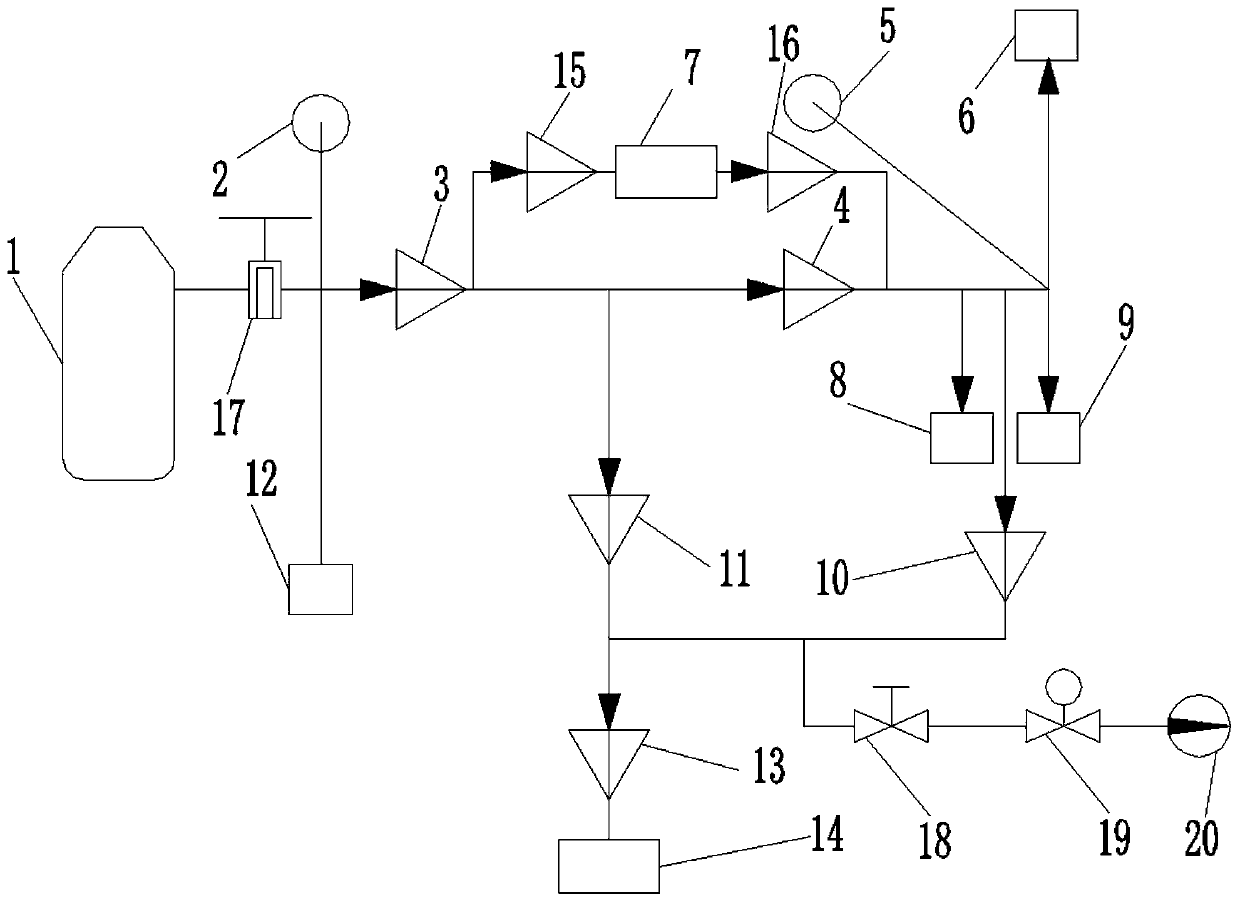

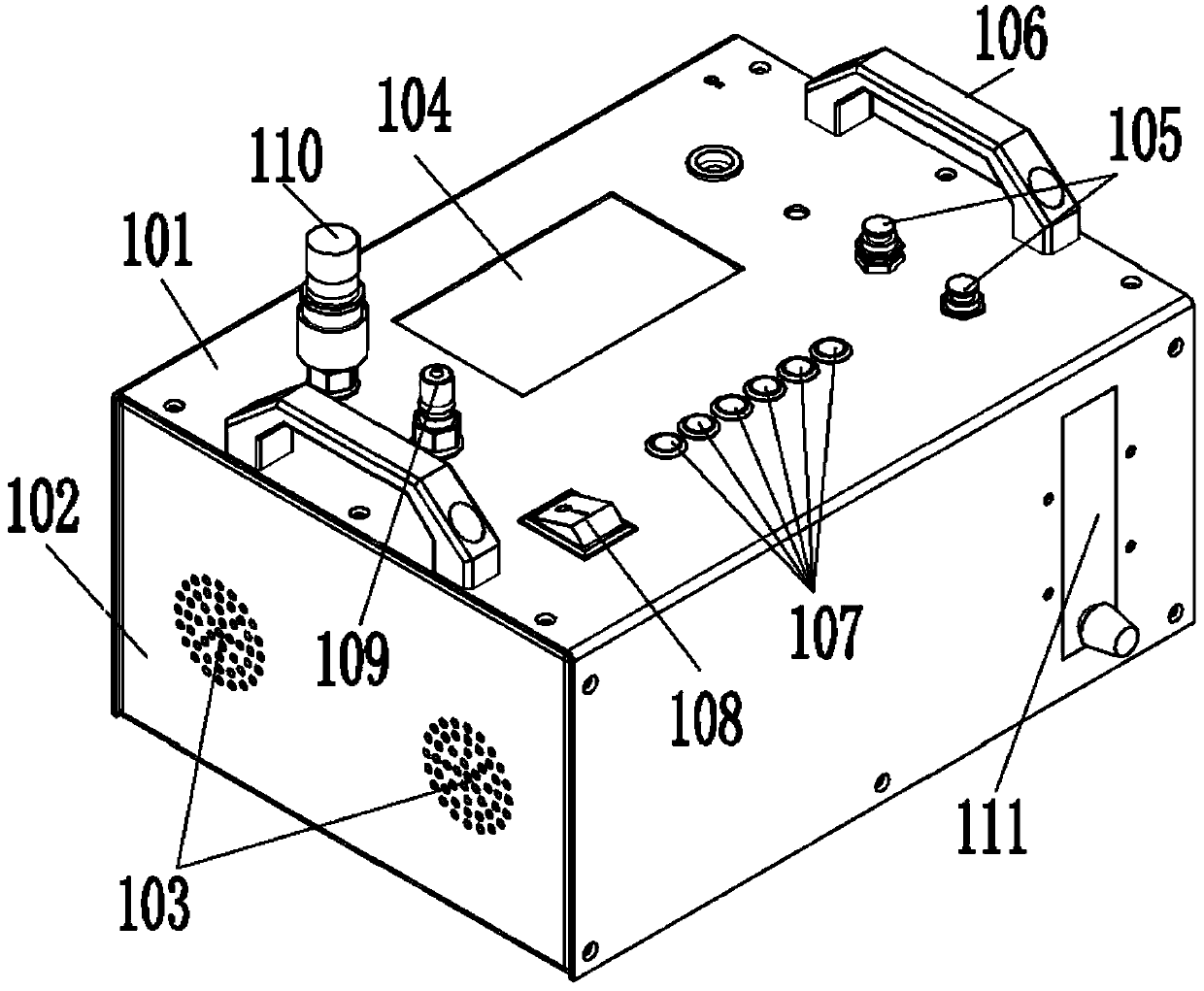

[0063] Such as Figure 1-13 As shown, it shows the specific implementation of the present invention, as shown in the figure, the sulfur hexafluoride air supply system disclosed by the present invention is used to fill the sulfur hexafluoride gas in the gas cylinder into the sulfur hexafluoride equipment Middle; Including an inflatable pipeline for supplementing air, one end of the inflatable pipeline is an air inlet connector for connecting with the gas cylinder, and the other end of the inflatable pipeline is an inflatable connector for connecting with the sulfur hexafluoride equipment 6;

[0064] The first solenoid valve 3 and the second solenoid valve 4 for controlling inflation are serially connected in series on the inflation pipeline; it also includes valves that communicate with the inflation pipeline through the exhaust pipeline and are connected in parallel with the first solenoid valve and the second solenoid valve respectively. The 3rd electromagnetic valve 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com