Lattice compound shaft structure and construction method

A lattice type, wellbore technology, applied in wellbore lining, shaft equipment, earth-moving drilling, etc., can solve the problems of easy generation of cracks, hidden dangers of engineering quality, weak well wall strength, etc. The effect of hidden dangers of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

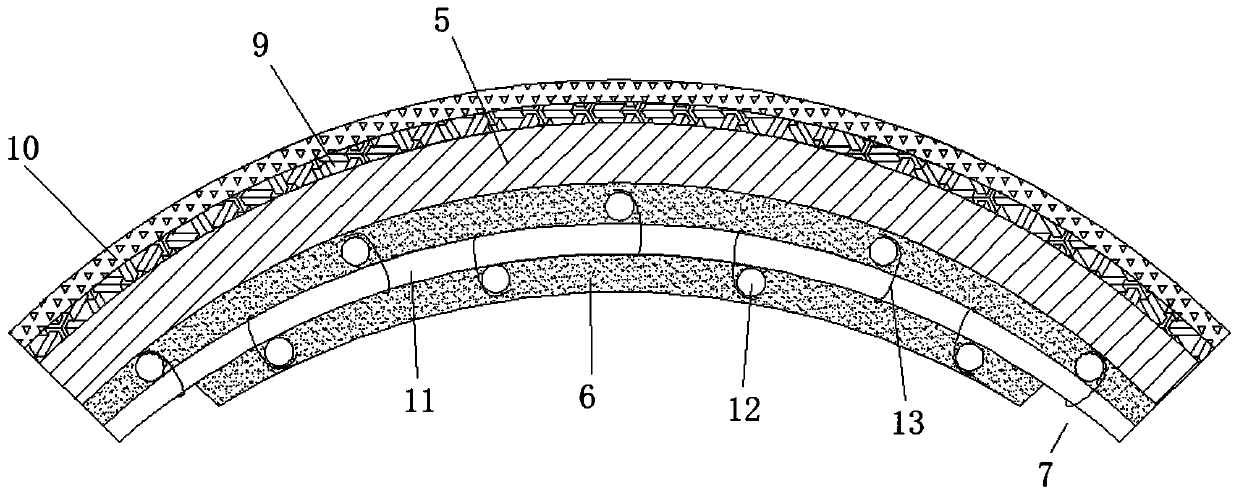

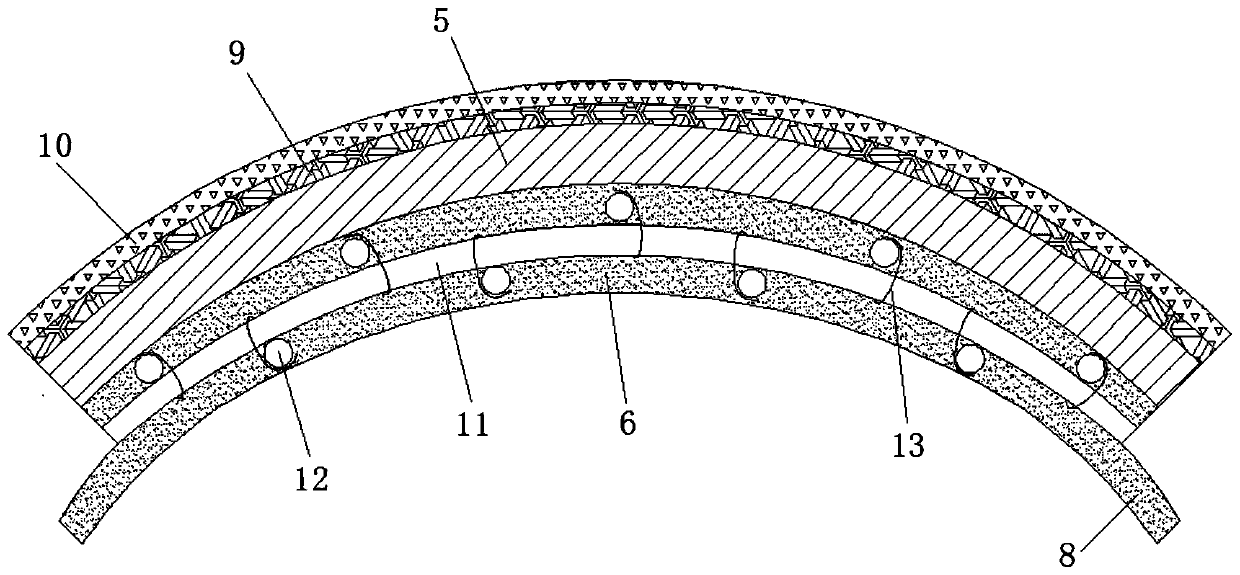

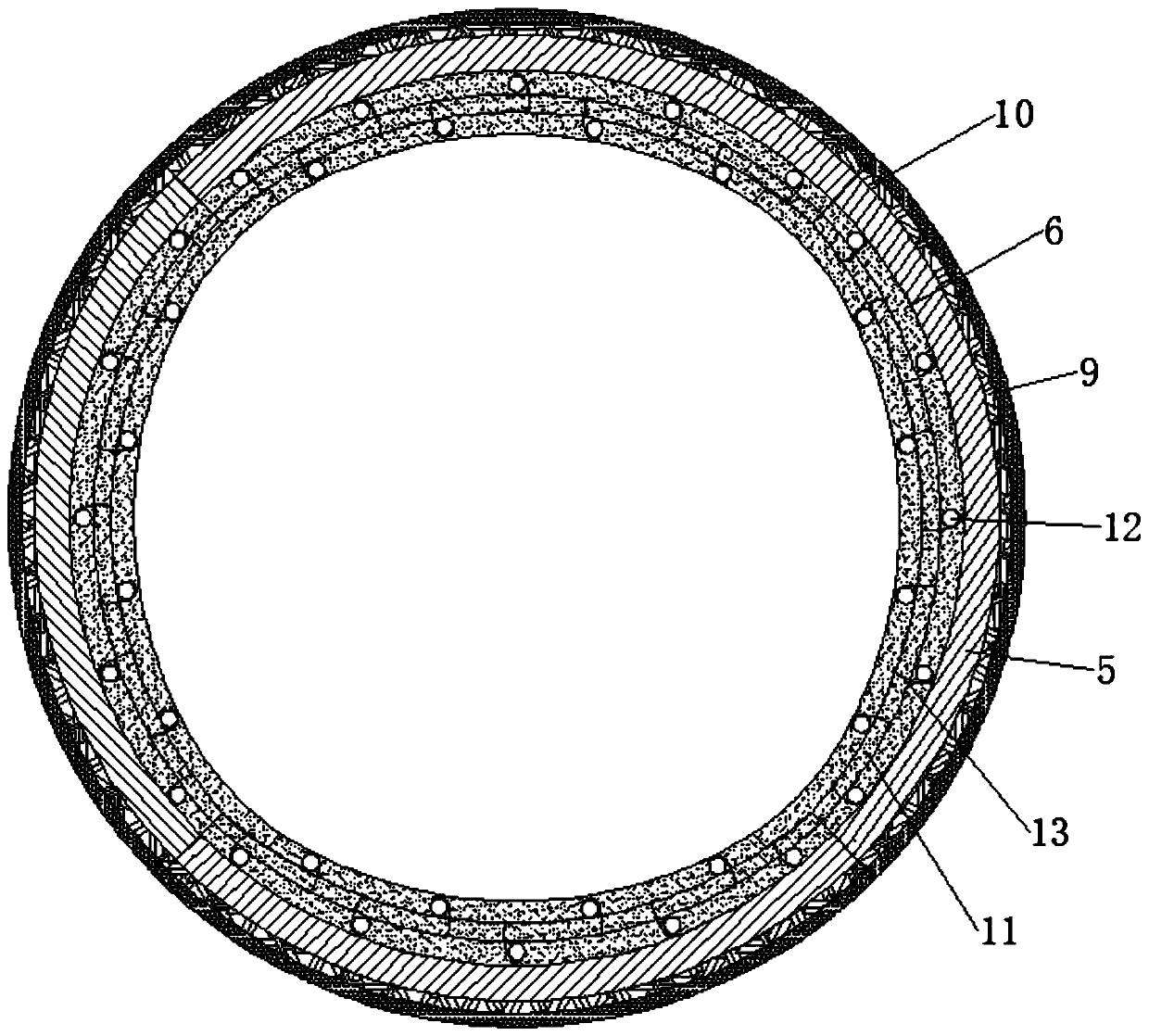

[0045] The invention provides a lattice type composite wellbore structure, specifically as Figure 1 to Figure 6 As shown, it includes an outer shaft and an inner shaft 1. There are multiple outer shafts, and the plurality of outer shafts are connected sequentially from top to bottom. The outer shaft is arranged in the excavated shaft and the outer wall is in contact with the shaft. 1 is installed in the outer shaft and the outer wall and the inner wall of the outer shaft are connected as a whole through concrete; in this embodiment, the outer shaft is prefabricated at a non-construction site, and after prefabrication, it is directly pulled to the construction site for hoisting, and the inner shaft 1 is at the construction site The construction is completed directly after hoisting the outer shaft of the outer well shaft.

[0046] Specifically, the outer wellbore is composed of at least two first cylinder walls 3 and two second cylinder walls 4, and the first cylinder walls 3 a...

Embodiment 2

[0067] Such as Figure 7 to Figure 9 As shown, in order to reduce the difficulty of hoisting, in this embodiment, at least four steel-shaped lattice columns 12 at the top and bottom of each outer shaft extend outward to form a plug-in end 14, and also include a plurality of crown beams 16, crown The top surface and the bottom surface of the beam 16 are provided with at least four installation holes 17 that cooperate with the plug-in ends 14, and a crown beam 16 is arranged between the upper and lower adjacent outer shafts, and the upper and lower adjacent outer shafts are plugged together. The end 14 and the mounting hole 17 are connected to the crown beam 16, and the rest of the structure is the same as that of Embodiment 1, and will not be repeated here. The height of the crown beam 16 is lower than the height of the outer shaft. During the hoisting process, the insertion end 14 and the installation hole 17 are easier to quickly and accurately locate and connect with each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com