Simulation crack module and crack-type drilling fluid plugging test device

A technology for simulating cracks and testing devices, which is used in surveying, earth-moving drilling, wellbore/well components, etc., and can solve the problems of difficulty in accurately evaluating the leakage-stopping effect, false blockage, and inability to reflect the blockage of the plugging agent. To achieve the effect of important research and engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

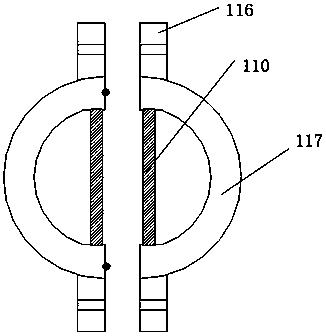

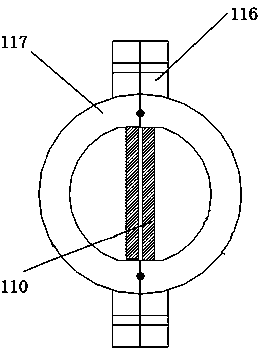

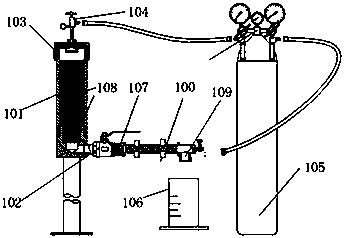

[0029] Such as Figure 1-Figure 5 As shown, a fracture-type drilling fluid plugging test device includes: a base, a sleeve 101, a sleeve cover 103, a ball valve 102 and a simulated fracture module 100. A simulated crack module 100, including: two identical semi-cylindrical members 117, in this embodiment, the material of the semi-cylindrical members 117 is metal, in other embodiments of the present invention, it can also be made of plastic or inorganic materials . In this embodiment, the two semi-cylindrical members 117 are connected by inserting positioning pins and screws into the connecting assembly 116. In other embodiments of the present invention, the two semi-cylindrical members 117 can also be connected by other detachable connection methods. A sealing groove is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com