Environment-friendly plastic runway and construction process thereof

A technology of plastic runway and construction technology, which is applied in the direction of roads, roads, road repairs, etc., can solve problems affecting the construction period, etc., and achieve the effect of convenient control of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

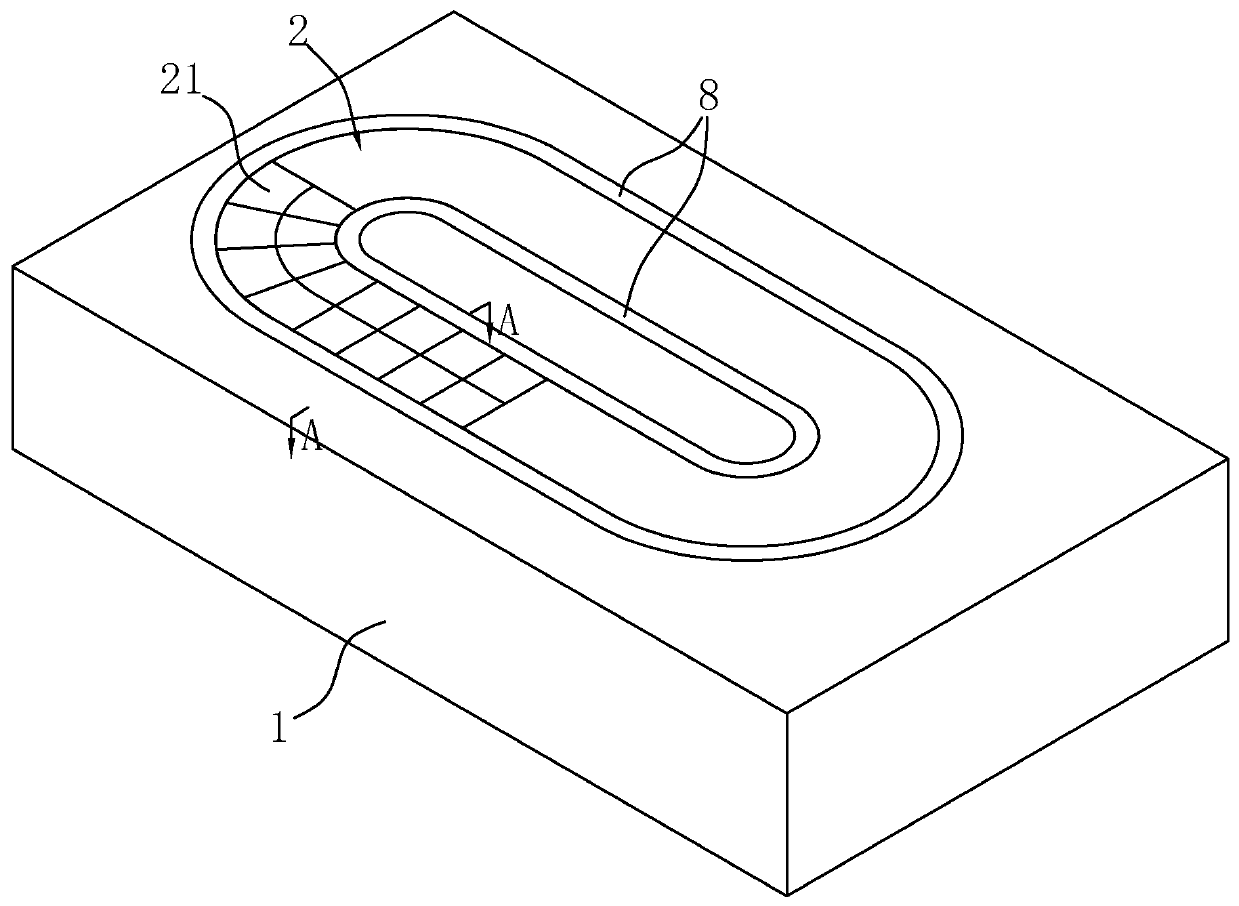

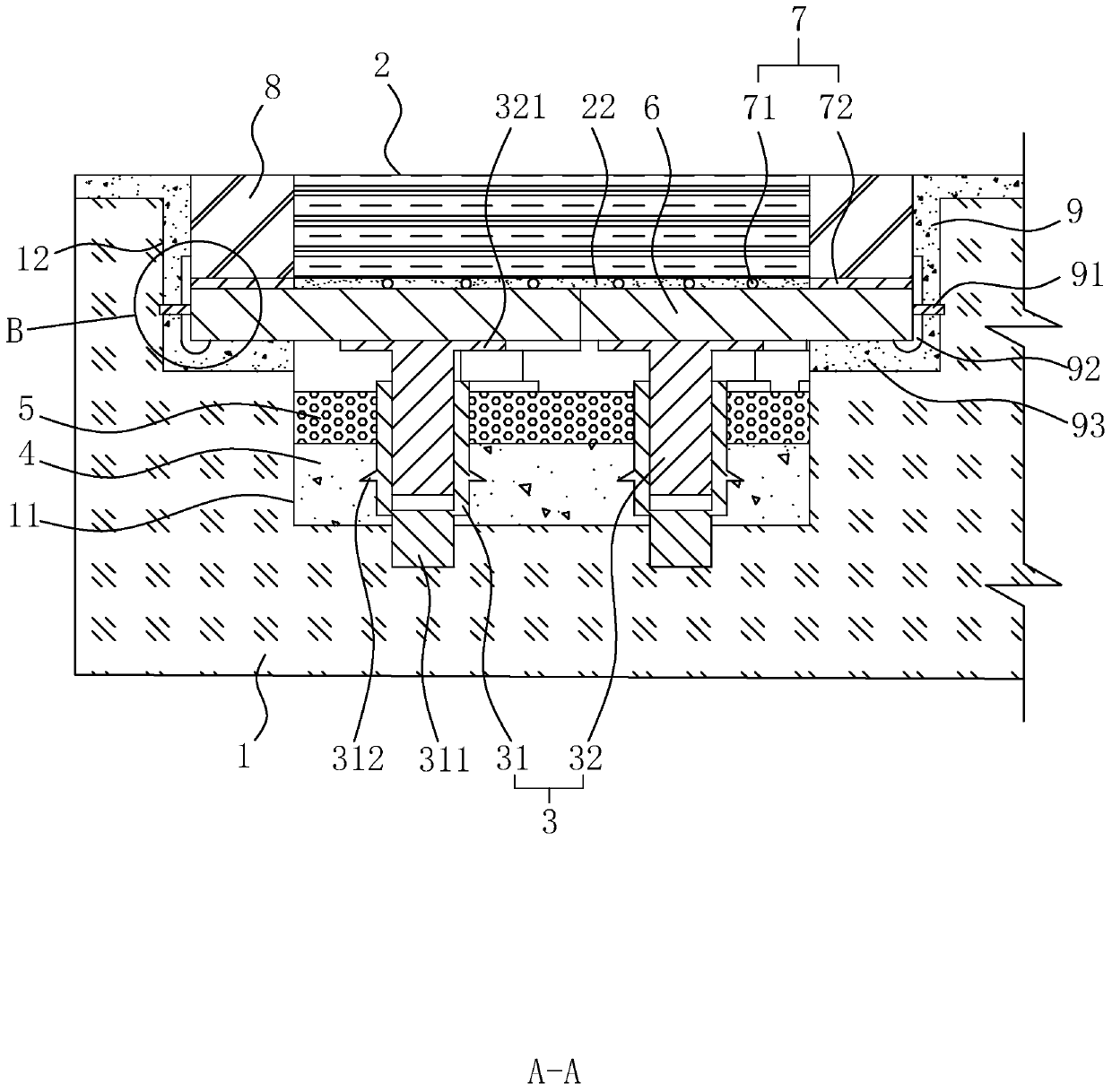

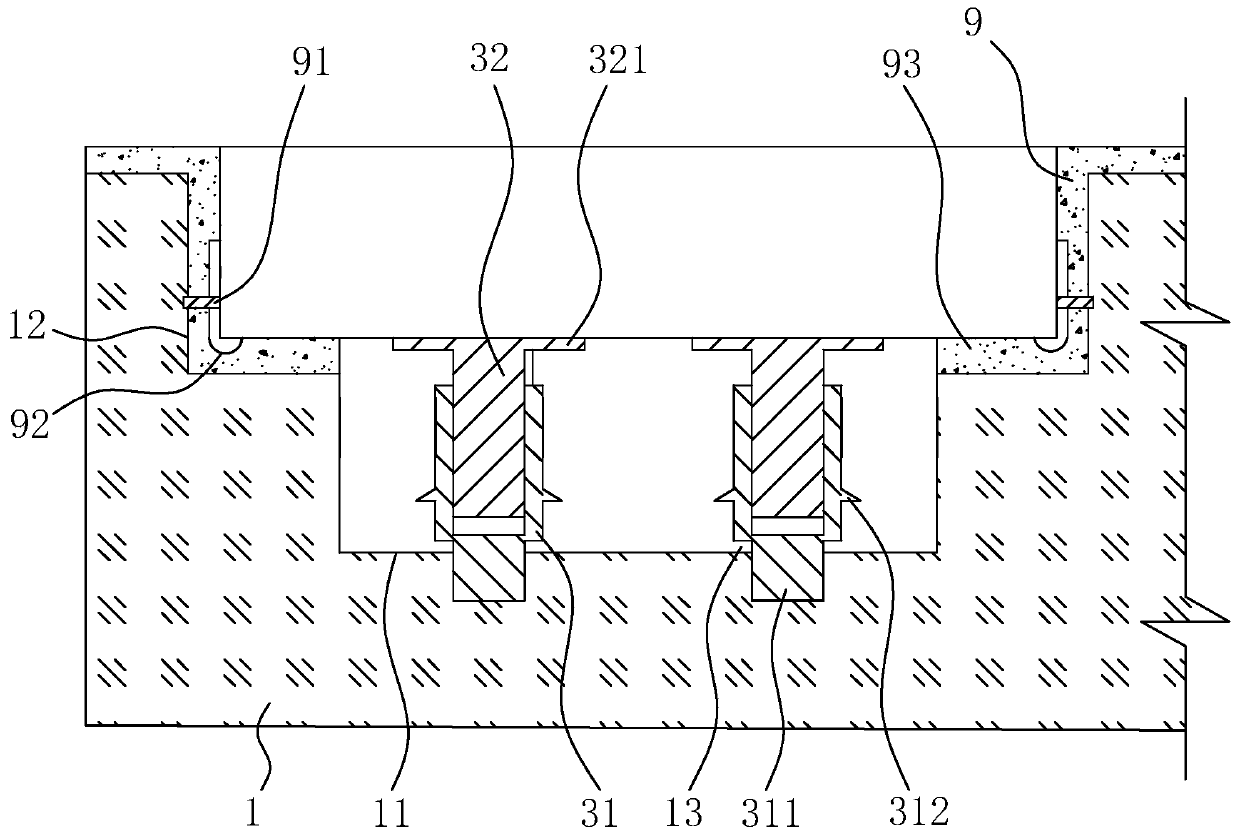

[0044] Embodiment: a kind of environment-friendly plastic runway, as figure 1 and figure 2 As shown, a ring-shaped foundation pit 11 is excavated on the foundation 1 according to the design size of the runway, and then the open sides of the foundation pit 11 are symmetrically widened to form widening grooves 12. The bottom of the foundation pit 11 is vertically fixed with multiple supporting components. 3. The foundation pit 11 is laid with a concrete layer 4 and a gravel layer 5 sequentially from bottom to top. The end of the support assembly 3 away from the ground is on the same level as the bottom wall of the widened groove 12. The support assembly 3 is supported by a support plate 6 , the end of the support plate 6 abuts against the widening groove 12 and is fixed, and the grid mesh 7 and the plastic layer 2 are sequentially laid and fixed on the top of the support plate 6. The top surface of the plastic layer 2 is flush with the ground, and the two sides of the plastic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com