Process method for reducing metallurgical defects of gh4169 nickel-base alloy ingot

A GH4169, nickel-based alloy technology, applied in metal processing equipment and other directions, can solve problems such as metallurgical defects and affect product quality, and achieve the effect of reducing defects, improving alloy purity, and reducing metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

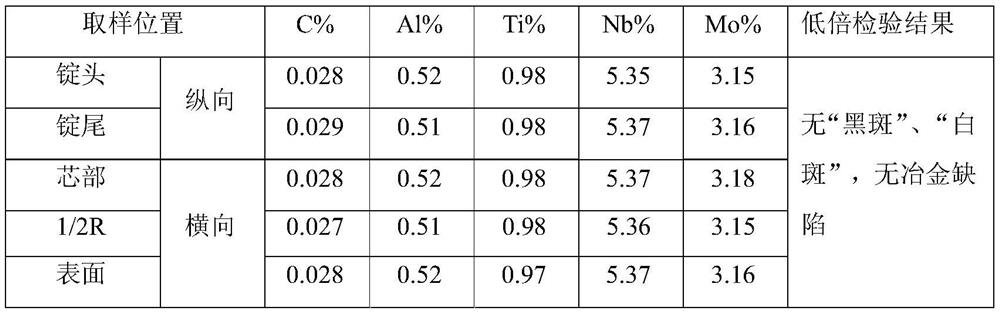

Embodiment 1

[0025] This embodiment is a method for producing a GH4169 nickel-based alloy ingot metallurgical defect using the present invention, by vacuum induction smelting, homogenization, fastging, and vacuum self-consuming weight, producing φ406mm specifications GH4169 alloy ingot.

[0026] Step A VIM Solmetry: Use a vacuum induction smelting (Vim) to melt the various raw materials into a Chemical component and the non-metal inclusions satisfying the required GH4169 alloy, and the vacuum cast into a alloy ingot having a diameter φ360 mm specification; step B homogenization processing: Put step The alloy ingot obtained by the diameter φ360mm specification is homogenized, and the homogenization temperature is 20 ° C below the GH4169 nickel-based alloy, and the homogenization time is 25h. Step c fast Forged tap: Use a 4500T press to perform a rough out of the alloy ingot of step B through the homogeneous process, the heating temperature is 1100 ° C, control the upset pressure rate of 30%, un...

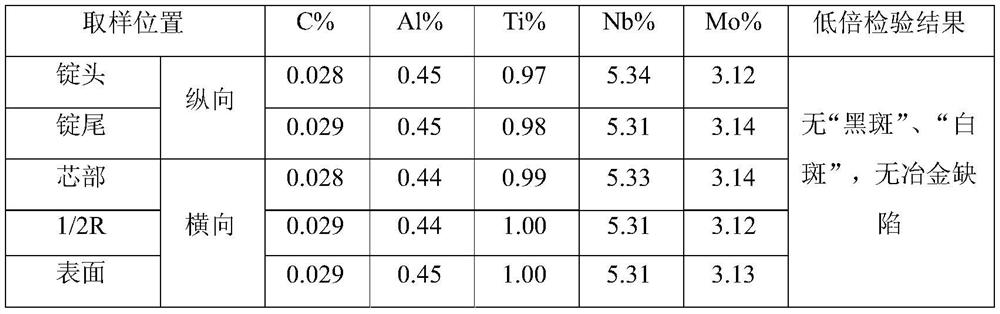

Embodiment 2

[0030] This embodiment is a method for producing a GH4169 nickel-based alloy ingot metallurgical defect using the present invention, by vacuum induction smelting, homogenization, fast forging, and vacuum self-consuming, and produces φ508 mm specifications GH4169 alloy ingot.

[0031]Step A VIM Solmetry: Use a vacuum induction smelting (VIM) to melt various raw materials into chemical composition and non-metal inclusions to satisfy the requirements of the GH4169 alloy, and the vacuum cast into a diameter φ450 mm-specific alloy ingot; step B homogenization: Put step A alloy ingot obtained by the diameter φ450mm specification is homogenized, and the homogenization temperature is 10 ° C below 10 ° C below the GH4169 nickel-based alloy, homogenized time 35 h. Step c fast Forged tap: Use a 4500T press to carry out step B through the alloy ingots of the homogenization, the heating temperature is 1120 ° C, control the upset ratio of 40%, unplug the lower pressure rate 20 %, GH4169 alloy i...

Embodiment 3

[0035] This embodiment is a method for producing a GH4169 nickel-based alloy ingot metallurgical defect using the present invention, by vacuum induction smelting, homogenization, fast forging, and vacuum self-consuming, and produces φ508 mm specifications GH4169 alloy ingot.

[0036] Step A VIM Solmetry: Use a vacuum induction smelting (VIM) to melt various raw materials into chemical composition and non-metal inclusions to satisfy the requirements of the GH4169 alloy, and the vacuum cast into a diameter φ450 mm-specific alloy ingot; step B homogenization: Put step The alloy ingot obtained by the diameter φ450mm specification is homogenized, the homogenization temperature is 20 ° C below the GH4169 nickel-based alloy, and the homogenization time is 40 h. Step c fast Forged tap: Use a 4500T press to make the step B through the alloy ingot of the homogenization process, the heating temperature is 1150 ° C, control the upset ratio of 35%, unplug the lower pressure rate 17 %, GH4169 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com