Silicified latex balloon as well as preparation method and application thereof

A siliconized and balloon technology, applied in the field of siliconized latex balloon and its preparation, can solve the problems of balloon burst, prolonged flushing time, lack of pressure on the balloon, etc., and achieves good biocompatibility and is not easy to cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

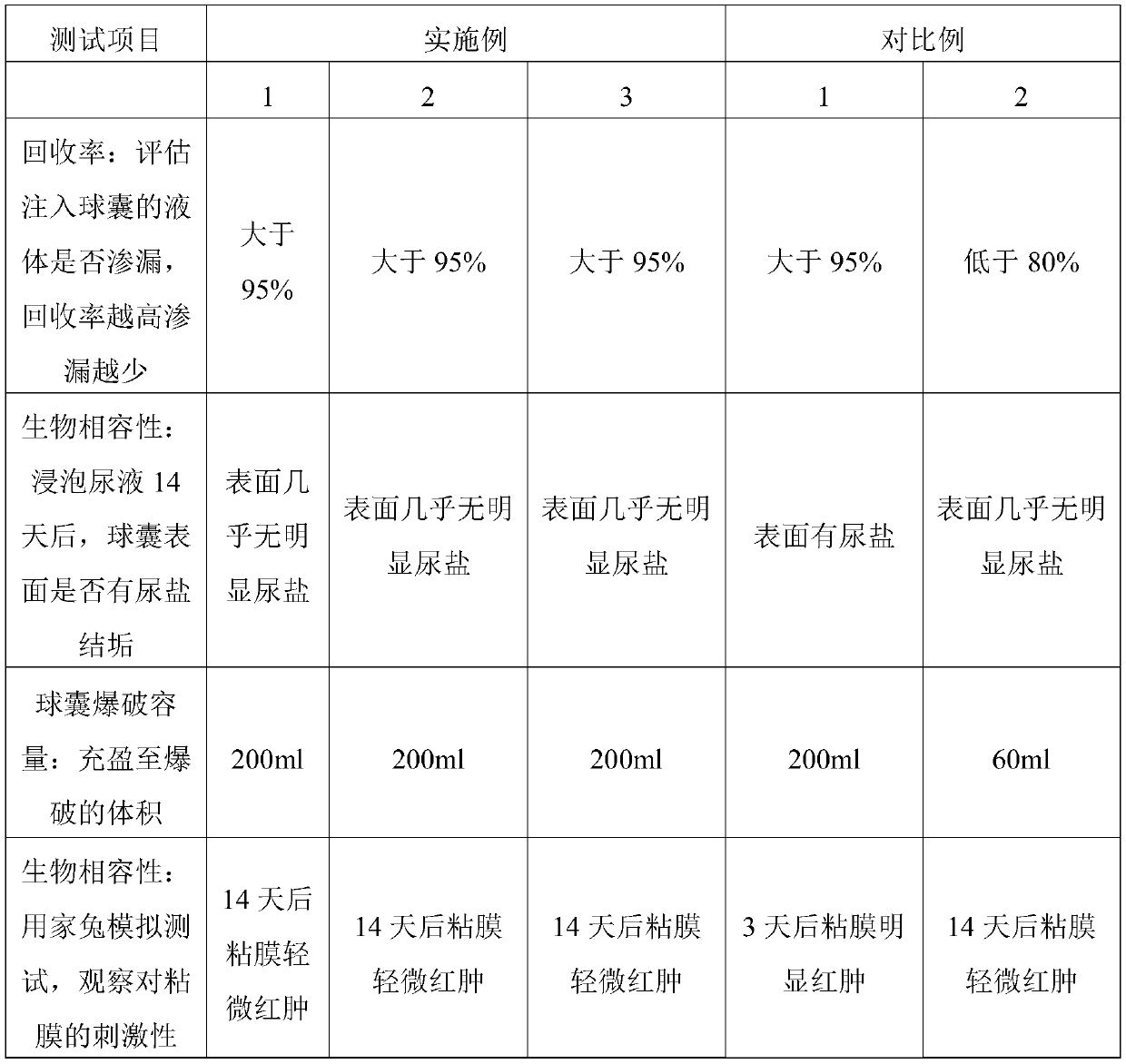

Examples

Embodiment 1

[0029] A preparation method of a siliconized latex balloon, comprising the following steps:

[0030] (1) Mix 10% calcium carbonate, 3% calcium nitrate and 87% ethanol to obtain a mixed coagulant, and then immerse the balloon mold in the mixed coagulant;

[0031] (2) Dip the balloon mold in the pre-vulcanized carboxyl nitrile latex for 30 seconds;

[0032] (3) dissolving 5% calcium nitrate in 95% ethanol to obtain a coagulant solution, and then immersing the balloon mold in the coagulant solution to obtain a molded film;

[0033] (4) Soak the formed film in water at 50°C, take it out and dry it at 45°C for 20 minutes;

[0034] (5) Demoulding the dried film, immersing the demoulded latex balloon in the silicone emulsion for 5 seconds, taking out the latex balloon, and curing it at 120°C for 3 seconds to obtain a siliconized latex balloon .

Embodiment 2

[0036] A preparation method of a siliconized latex balloon, comprising the following steps:

[0037] (1) Mix 8% calcium carbonate, 4% calcium nitrate and 88% ethanol to obtain a mixed coagulant, and then immerse the balloon mold in the mixed coagulant;

[0038] (2) Dip the balloon mold in the pre-vulcanized carboxyl nitrile latex for 30 seconds;

[0039] (3) dissolving 5% calcium nitrate in 95% ethanol to obtain a coagulant solution, and then immersing the balloon mold in the coagulant solution to obtain a molded film;

[0040] (4) Soak the formed film in water at 50°C, take it out and dry it at 45°C for 20 minutes;

[0041] (5) Demoulding the dried film, immersing the demoulded latex balloon in the silicone emulsion for 5 seconds, taking out the latex balloon, and curing it at 120°C for 3 seconds to obtain a siliconized latex balloon .

Embodiment 3

[0043] A preparation method of a siliconized latex balloon, comprising the following steps:

[0044] (1) Mix 5% calcium carbonate, 3% calcium nitrate and 92% ethanol to obtain a mixed coagulant, and then immerse the balloon mold in the mixed coagulant;

[0045] (2) Dip the balloon mold in the pre-vulcanized carboxyl nitrile latex for 30 seconds;

[0046] (3) dissolving 5% calcium nitrate in 95% ethanol to obtain a coagulant solution, and then immersing the balloon mold in the coagulant solution to obtain a molded film;

[0047] (4) Soak the formed film in water at 50°C, take it out and dry it at 45°C for 20 minutes;

[0048] (5) Demoulding the dried film, immersing the demoulded latex balloon in the silicone emulsion for 5 seconds, taking out the latex balloon, and curing it at 120°C for 3 seconds to obtain a siliconized latex balloon .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com