A kind of vinyl acetylene refining method

A vinyl acetylene and refining method technology, applied in chemical instruments and methods, absorption purification/separation, organic chemistry, etc., can solve the problems of reducing organic phase, unqualified quality, excessive content, etc., to achieve convenient separation and improve purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

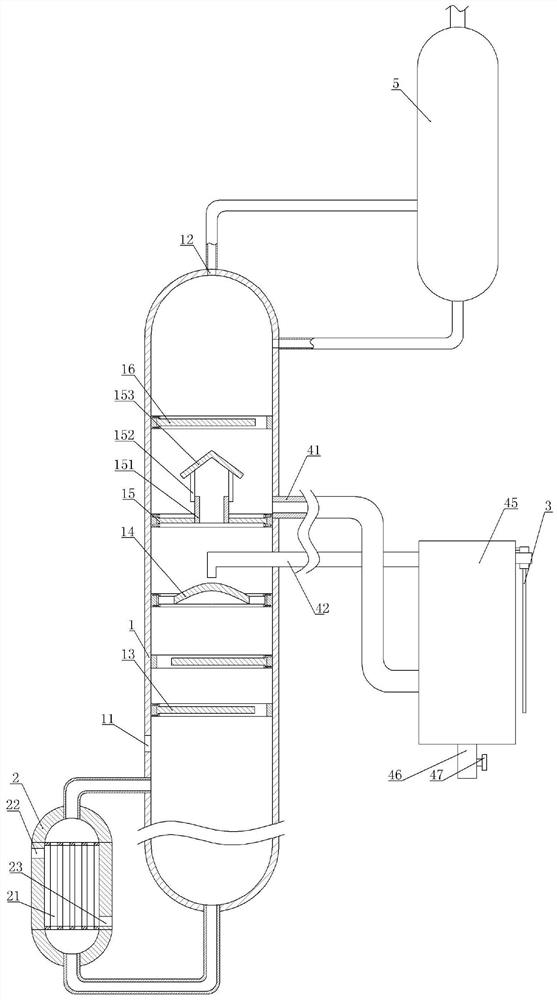

[0034] The reference signs in the accompanying drawings of the description include: tower body 1, feed inlet 11, outlet 12, first tray 13, dispersion disc 14, fourth tray 15, gas channel 151, support rod 152, Umbrella cover 153, fifth tray 16, reboiler 2, column tube 21, steam inlet 22, condensed water outlet 23, interface meter 3, liquid phase outlet pipe 41, liquid phase inlet pipe 42, water separator 45, Drain pipe 46, drain valve 47, tower top condenser 5.

[0035] The embodiment is basically as attached figure 1 Shown:

[0036] A method for refining vinyl acetylene, comprising the following steps:

[0037] Step 1: Preheat the absorption liquid obtained through the degassing tower to 70-75°C, and then pass it into the desorption tower from the middle of the degassing tower;

[0038] Step 2: Use steam to heat the absorption liquid passing into the desorption tower at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com