Lifting device for large compartment of refitted vehicle

A hoisting device, electric technology, applied in the direction of hoisting device, lifting equipment safety device, load block, etc., can solve the problems of unfavorable workpiece positioning, shaking, easy to hit the construction personnel, etc., to facilitate the modification work and increase the applicability , the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

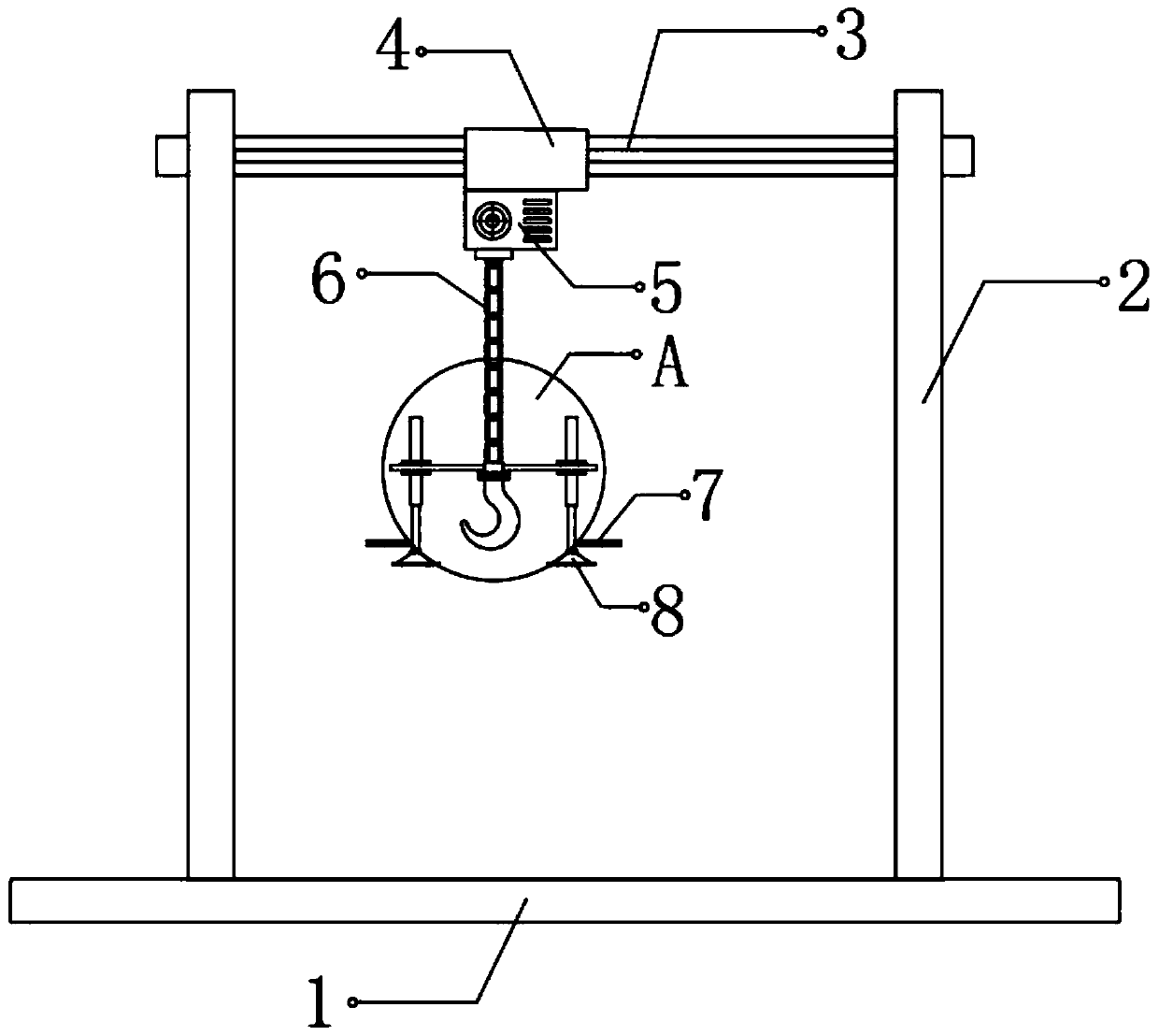

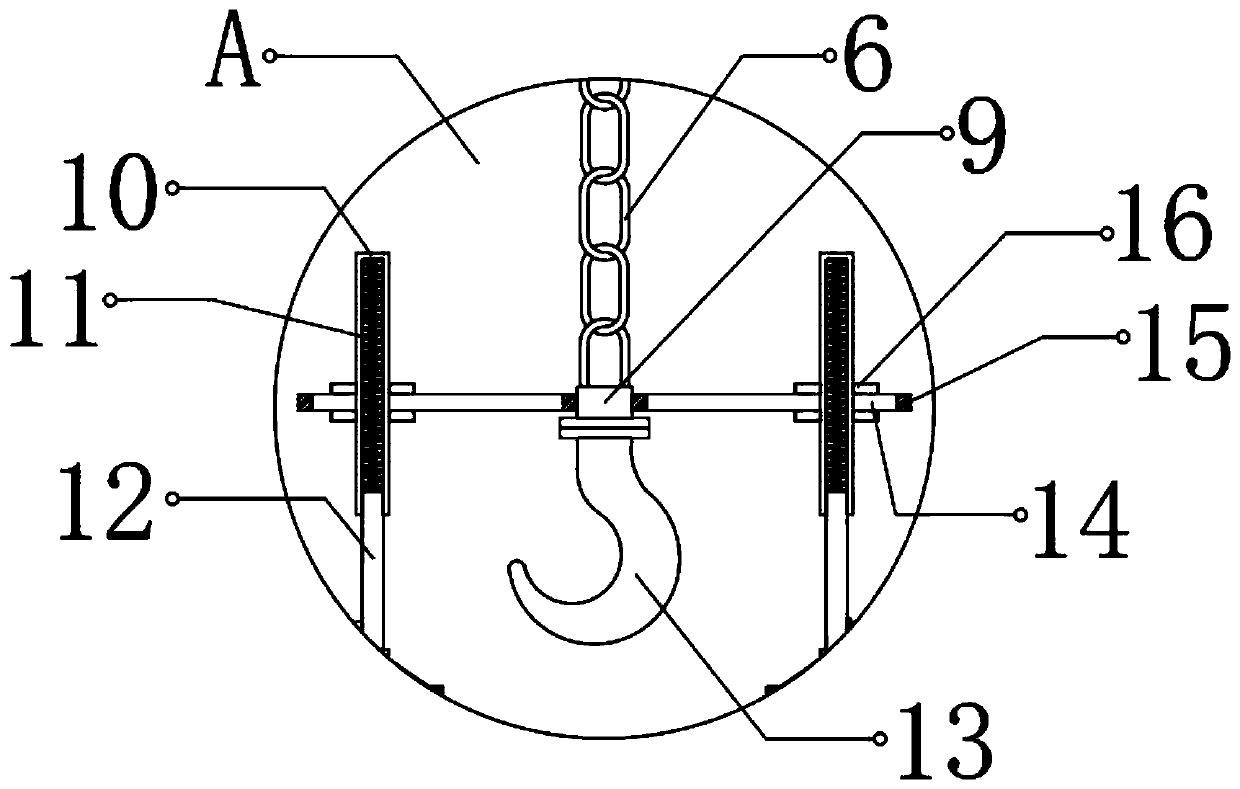

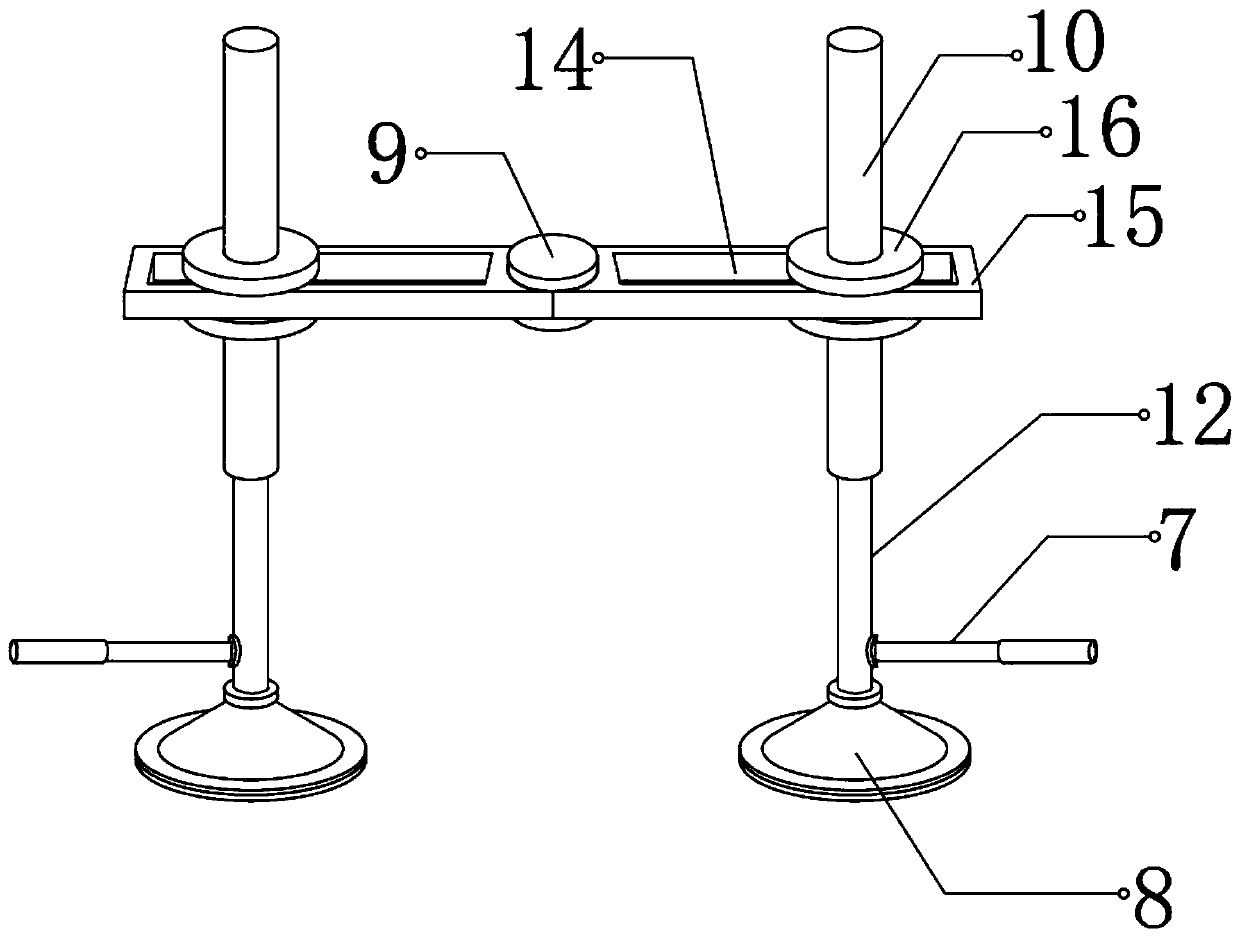

[0027] refer to Figure 1-3 , a lifting device for a large compartment of a refitted car, comprising a base 1, a bracket 2 and an electric slide rail 3, the two brackets 2 are fixedly connected to both sides of the top of the base 1, and the electric slide rail 3 is fixedly connected to the two brackets 2 The top of the electric slide rail 3 is slidably connected with a slider 4, and the bottom of the slider 4 is fixedly connected with a crane 5, and the reel inside the crane 5 is wound with an iron chain 6, and the bottom of the iron chain 6 is fixedly connected with a Fixed block 9, the bottom of fixed block 9 is fixedly connected with suspension hook 13, and both sides of fixed block 9 are all provided with reinforcing mechanism, refitting workpiece is articulated below suspension hook 13, and workpiece is hung by crane 5 and iron chain 6 Transport, crane 5 can slide on electric slide rail 3 by slide block 4, and two reinforcement mechanisms reinforce the two ends of workpi...

Embodiment 2

[0035] refer to Figure 4 , a lifting device for a refitted car compartment. Compared with Embodiment 1, the two sides of the top of the base 1 are connected with elevators 17 by bolts, and the tops of the two elevators 17 are welded with evenly distributed guardrails. 18.

[0036] Working principle: the staff stands on the top of the elevator 17, and the guardrail 18 plays a protective role. The elevator 17 can realize a certain range of height adjustment, which is convenient for the staff to carry out vehicle refitting work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com