Integrated egg tray transfer device

A transfer device, egg tray technology, applied in conveyors, loading/unloading, mechanical conveyors, etc., can solve the problems of no limit components, easy to use dislocation, etc., to avoid static friction, prolong service life, and smooth transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

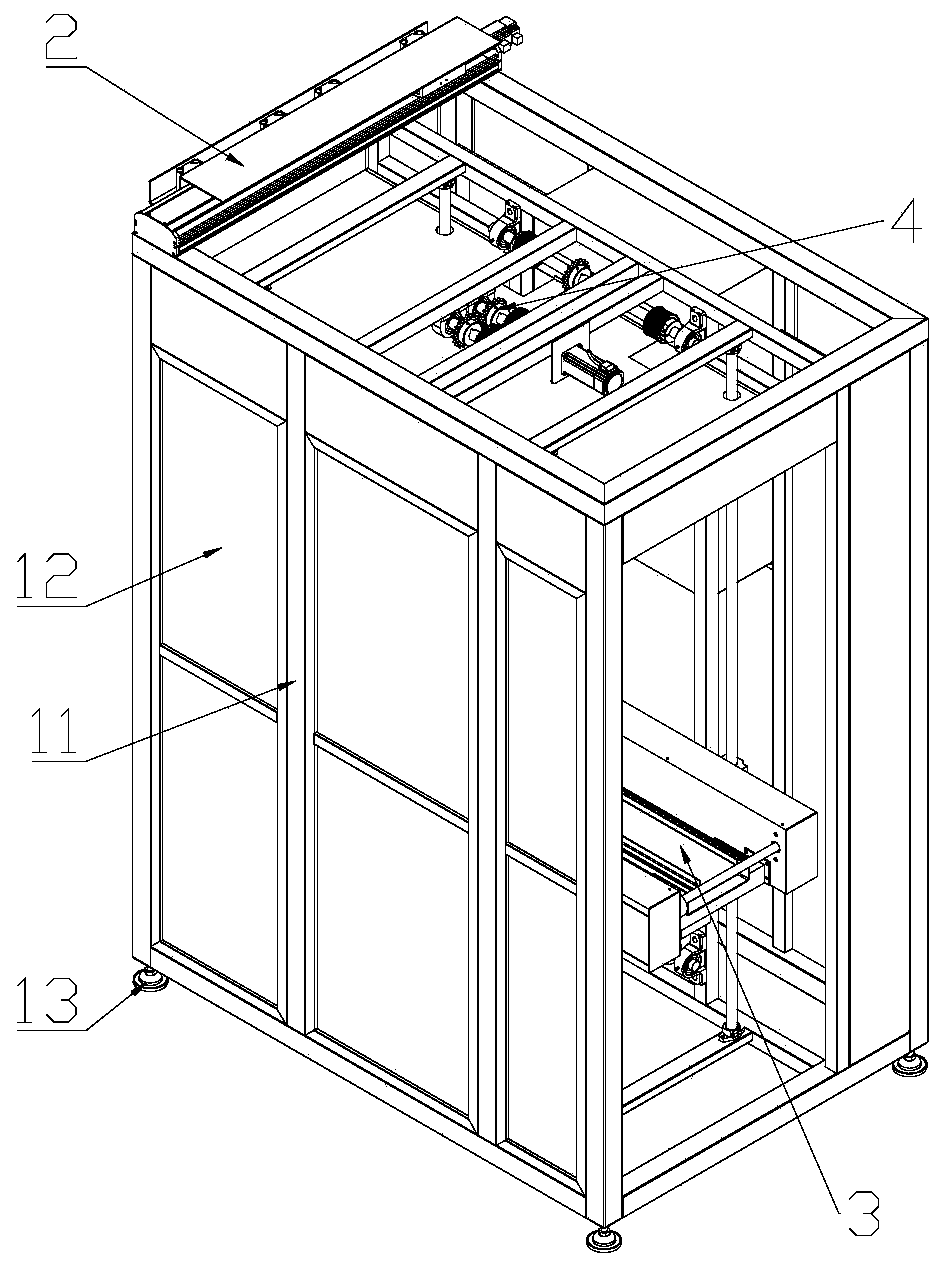

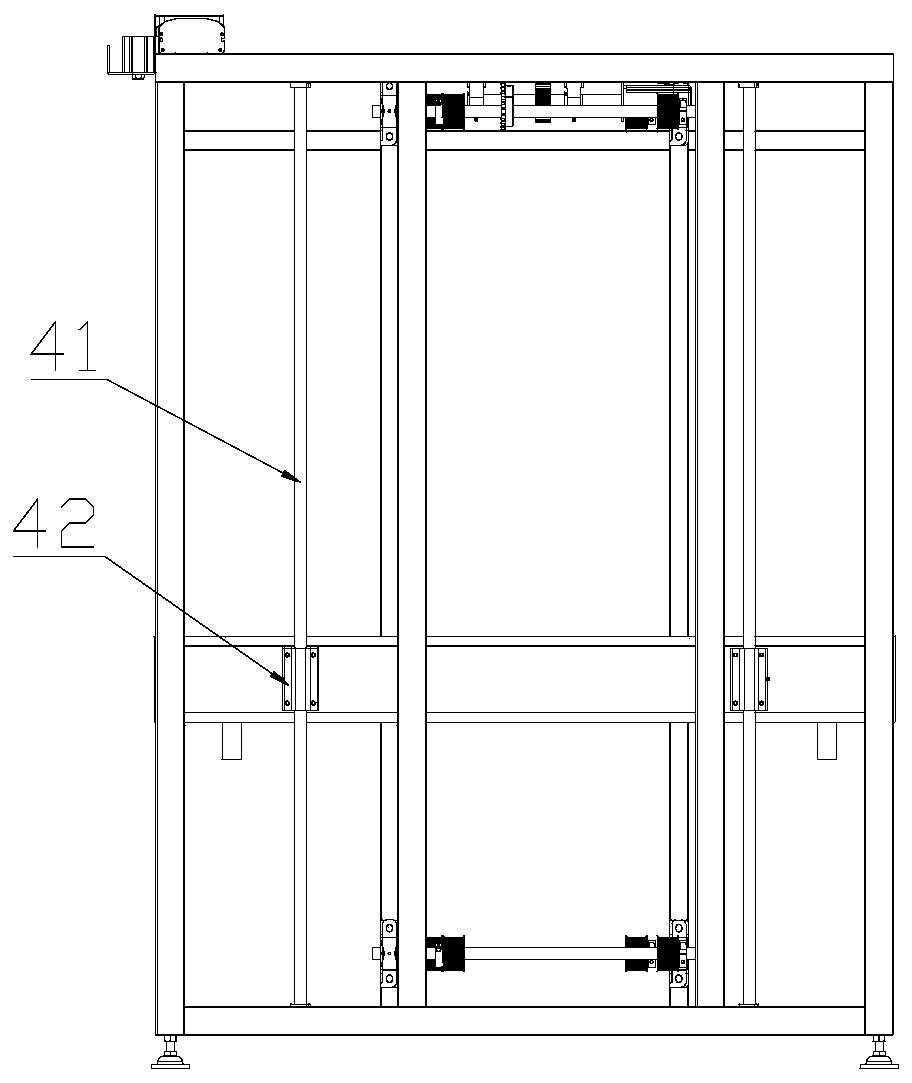

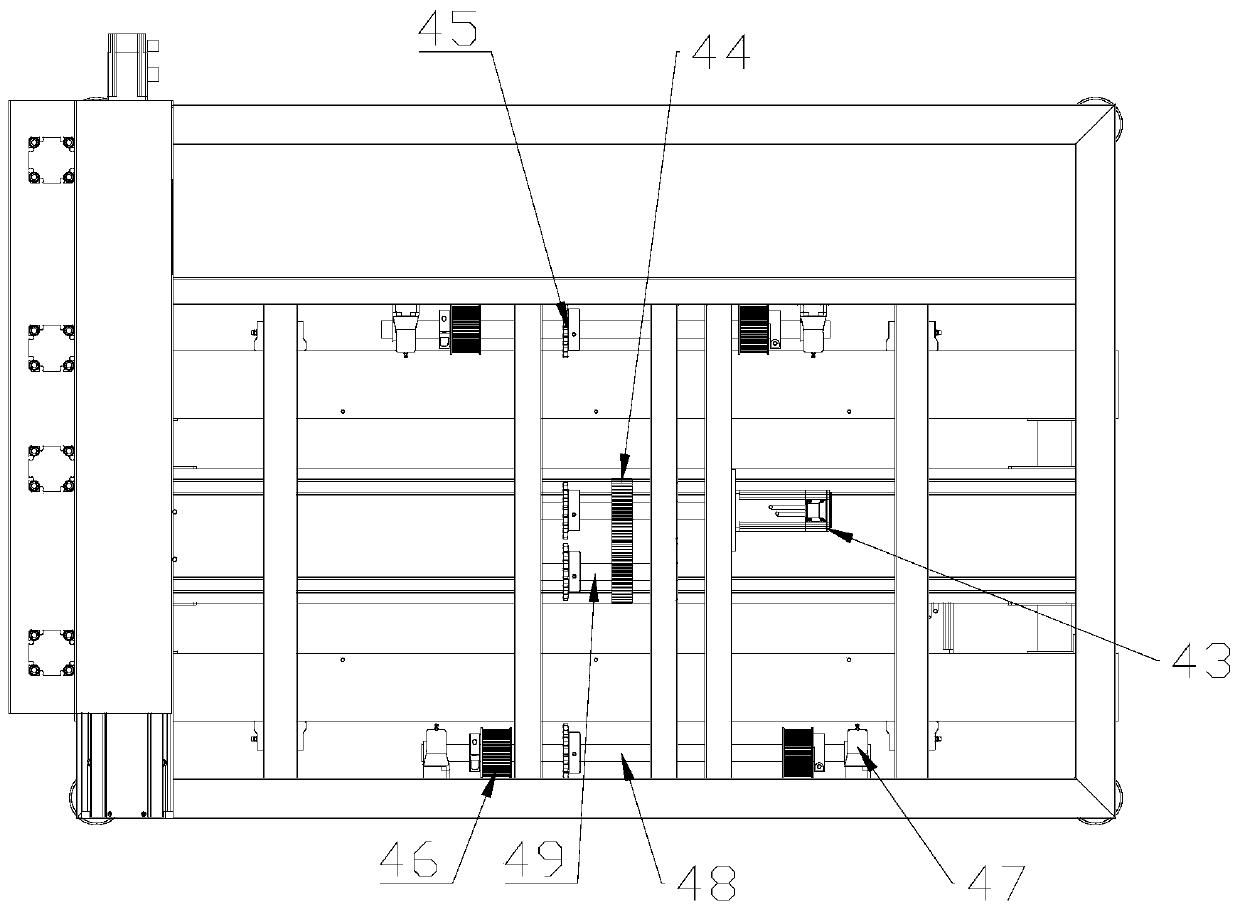

[0066] Such as figure 1 , 4 As shown in and 5, the integrated egg tray transfer device includes a frame 1, a transfer mechanism and a limit assembly 2, the limit assembly 2 is connected to one end of the frame 1, and the limit assembly 2 is used to adjust the egg trolley and the egg tray The disk is limited. The limit assembly 2 includes a fixed seat 24, a fixed frame 22, a limit motor 21, a first transmission element and a limit assembly, the fixed seat 24 is connected to the frame 1, and the fixed frame 22 slides through a provided The block 23 is slidably connected to the fixed seat 24, and the sliding block 23 is connected to the limit motor 21 through the first transmission element.

[0067] The limiting assembly 2 includes a plurality of limiting cylinders 25, and the cylinder rods of the plurality of limiting cylinders 25 all point to the transfer mechanism.

[0068] By setting the limit component 2, the limit component 2 is used to limit the position of the egg trol...

Embodiment 2

[0070] Such as Figure 1-8 As shown, the integrated egg tray transfer device includes a frame 1, a transfer mechanism, and a limit assembly 2. The limit assembly 2 is connected to one end of the frame 1, and the limit assembly 2 is used to control the egg trolley and the egg tray. limit. The limit assembly 2 includes a fixed seat 24, a fixed frame 22, a limit motor 21, a first transmission element and a limit assembly, the fixed seat 24 is connected to the frame 1, and the fixed frame 22 slides through a provided The block 23 is slidably connected to the fixed seat 24, and the sliding block 23 is connected to the limit motor 21 through the first transmission element.

[0071] The limiting assembly 2 includes a plurality of limiting cylinders 25, and the cylinder rods of the plurality of limiting cylinders 25 all point to the transfer mechanism.

[0072] By setting the limit component 2, the limit component 2 is used to limit the position of the egg trolley and the egg tray, ...

Embodiment 3

[0087] Such as Figure 1-8 As shown, the integrated egg tray transfer device includes a frame 1, a transfer mechanism, and a limit assembly 2. The limit assembly 2 is connected to one end of the frame 1, and the limit assembly 2 is used to control the egg trolley and the egg tray. limit. The limit assembly 2 includes a fixed seat 24, a fixed frame 22, a limit motor 21, a first transmission element and a limit assembly, the fixed seat 24 is connected to the frame 1, and the fixed frame 22 slides through a provided The block 23 is slidably connected to the fixed seat 24, and the sliding block 23 is connected to the limit motor 21 through the first transmission element.

[0088] The limiting assembly 2 includes a plurality of limiting cylinders 25, and the cylinder rods of the plurality of limiting cylinders 25 all point to the transfer mechanism.

[0089] By setting the limit component 2, the egg trolley and the egg tray are limited by the limit component 2, so as to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com