Hob die-cutting system and method for oca optical glue with four-layer 1:1 structure

An optical adhesive and die-cutting technology, which is applied in the field of hob die-cutting system of OCA optical adhesive, can solve the problems of poor quality, misalignment and contamination in the adhesive tape lamination process, and achieves improvement of flatness and warpage, improving quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

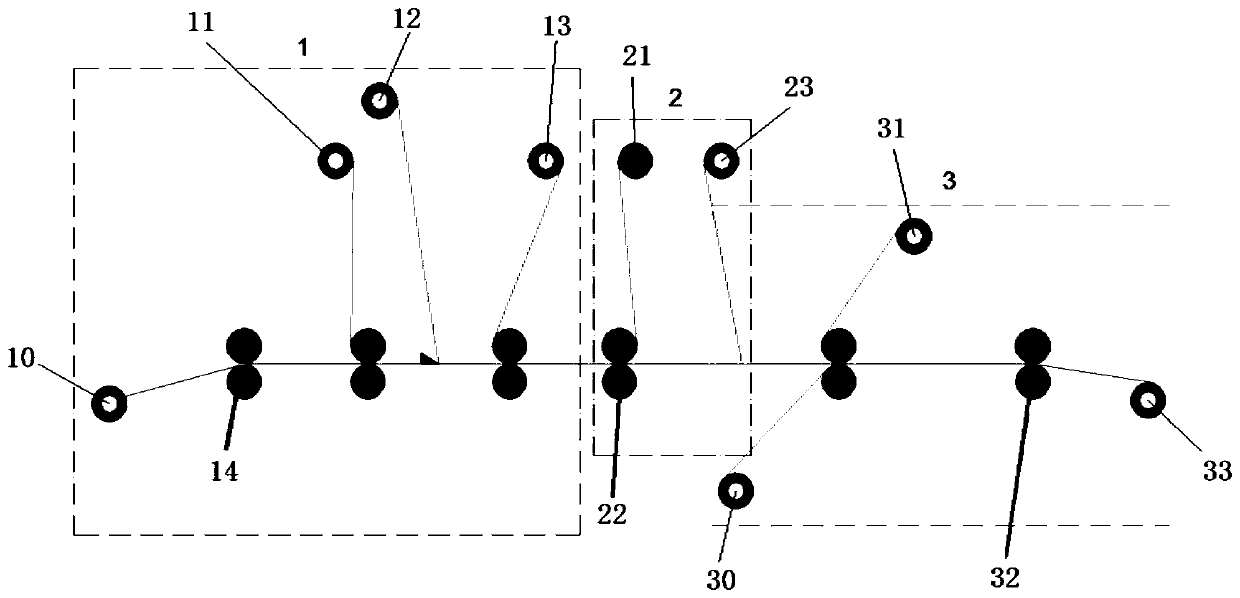

[0032] A hob die-cutting system for an OCA optical adhesive with a four-layer 1:1 structure of the present invention includes a laminating part 1, a die-cutting part 2, a process part 3 and a number of laminating wheel sets arranged in sequence;

[0033] The laminating part 1 includes a first discharge shaft 10, a second discharge shaft 11, and a third discharge shaft 13 that discharge materials in sequence. The first discharge shaft 10 is used to transport the carrier tape, and the second discharge shaft The shaft 11 is used to transport the OCA composite film, the OCA composite film includes a surface layer, a first functional layer, and a second functional layer arranged in sequence, and the third discharge shaft 13 is used to transport the light film in the process; the second discharge shaft A surface layer removal mechanism 12 for removing the surface layer is provided between 11 and the third discharge shaft 13. Under the action of the pressing wheel set, the shipping ca...

Embodiment 2

[0039] The present embodiment provides a method for hob die-cutting using the above-mentioned hob die-cutting system, comprising the following steps:

[0040] (1) Fitting: the first unwinding shaft 10 is used to transport the shipping carrier tape, the unwinding tension is set to 13N, and the groove making part of the groove making mechanism 14 is used to open a groove in the output shipping carrier tape. The width of the groove is smaller than the width of the OCA composite film attached to it, and the slotted waste produced by the grooved part is wound by the waste winding part. Then use the second unwinding shaft 11 to transport the OCA composite film. The OCA composite film includes a surface layer, a first functional layer, and a second functional layer arranged in sequence from top to bottom. The unwinding tension is set to 35N. Under the action, the second functional layer is attached above the shipping carrier tape, the first functional layer is located on the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com