Two-rotation and one-move series-parallel parallel driving swing head mechanism with follow-up constraint

A hybrid and follow-up technology, applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large space occupied by the drive rod, singularity of layout form, and high requirements for servo motors, so as to avoid singularity problems and structure Compact and dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

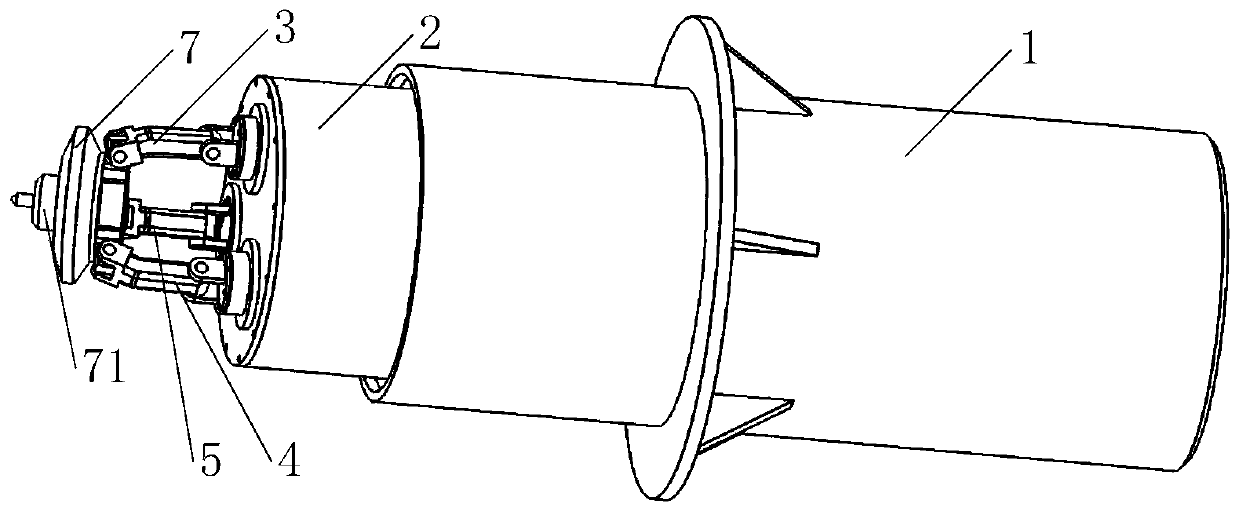

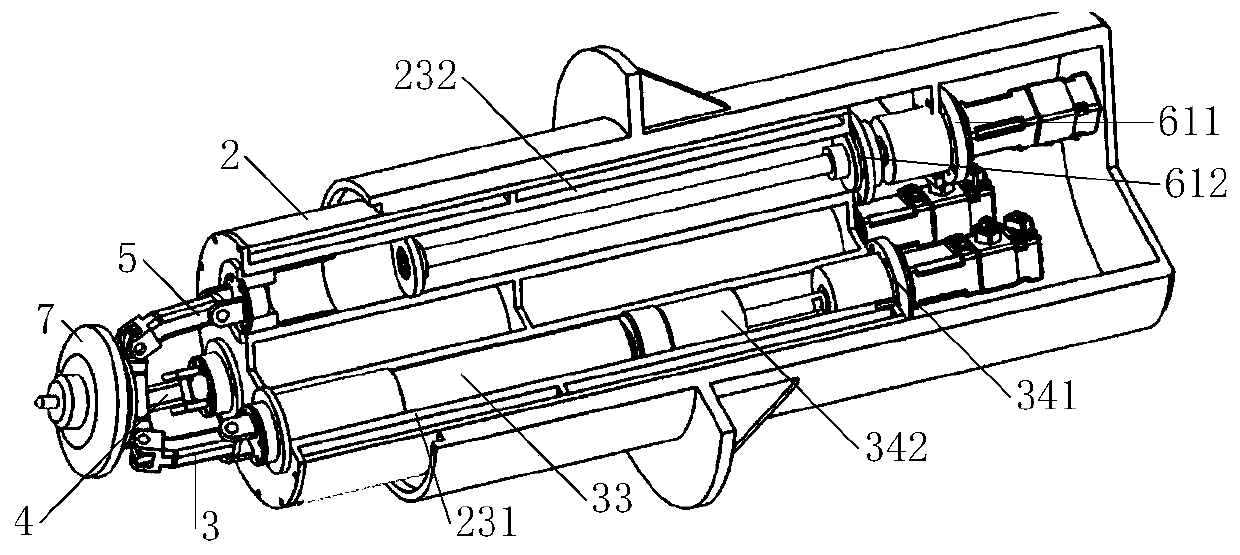

[0037] A two-rotation-one-shift hybrid parallel drive swing head mechanism with follow-up constraints, which mainly includes a mounting frame 1, an extension body 2, a first extension cylinder 33, a second extension cylinder 43, a first straight line The driving unit 34 , the second linear driving unit 44 , the third linear driving unit 61 , the first connecting rod 31 , the second connecting rod 41 , the third connecting rod 51 , the moving platform 7 and the electric spindle 71 . The two protruding cylinders adopt hollow steel pipes, and the protruding body 2 adopts the process of welding the hollow cylinder and the steel plate.

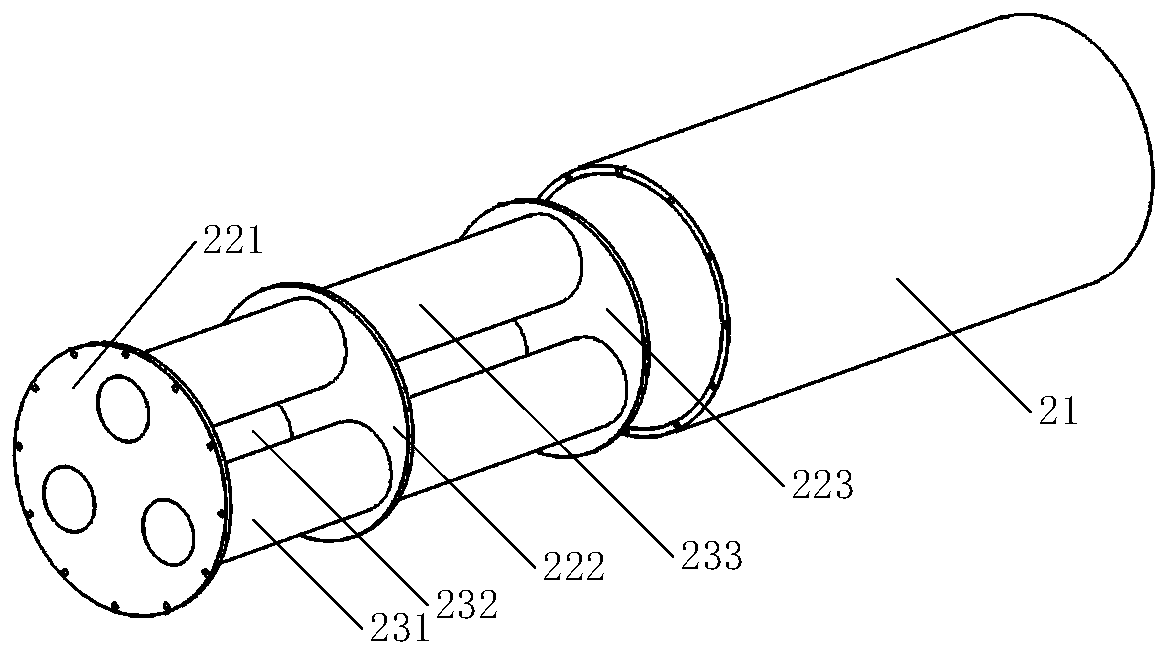

[0038] The extension body 2 includes an outer cylinder layer 21, an upper connecting plate 221, an intermediate connecting plate 222, a lower connecting plate 223, a first thin cylindrical tube 231, a second thin cylindrical tube 232 and a third thin cylindrical tube 233; each connecting plate There are three through holes evenly distributed at 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com