A Flux-Cored Welding Wire Containing Compound Rare Earth Elements Suitable for Welding 1000mpa Ultra-High-Strength Steel

A technology of flux-cored welding wire and compound rare earth, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of crack sensitivity, low toughness and strength of welded joints, etc., to improve plasticity, refine structure and crystallinity grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

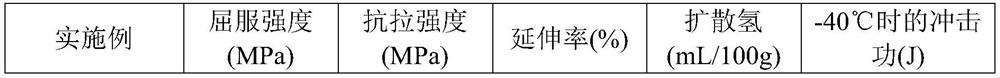

Examples

Embodiment 1

[0037] A flux-cored welding wire containing compound rare earth elements suitable for welding 1000MPa ultra-high-strength steel proposed in this embodiment is composed of a flux core and a low-carbon steel strip coated on the outside of the flux core. The flux core includes the following components according to the mass fraction of the welding wire : C: 0.32%, Si: 0.22%, Mn: 1.25%, Cr: 1.2%, Ni: 2.5%, Mo: 0.55%, Ti: 0.33%, Zr: 0.08%, La: 0.05%, Ce: 0.05% , Pr: 0.02%, Er: 0.02%, Y: 0.03%, Sc: 0.015%, and the rest is iron.

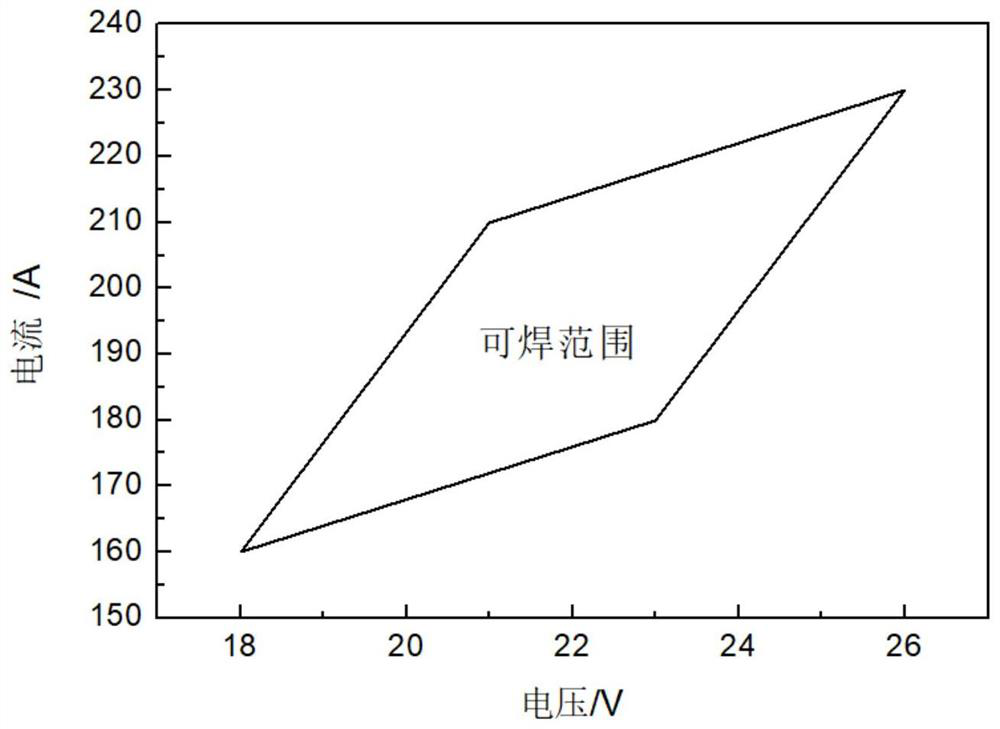

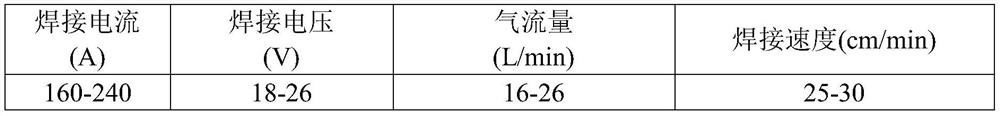

[0038] The welding wire is drawn to Φ1.2mm according to the conventional preparation method, and its welding process window is as follows figure 1 shown.

[0039] The filling rate of the flux cored wire is 25.5%.

Embodiment 2

[0041] A flux-cored welding wire containing compound rare earth elements suitable for welding 1000MPa ultra-high-strength steel proposed in this embodiment is composed of a flux core and a low-carbon steel strip coated on the outside of the flux core. The flux core includes the following components according to the mass fraction of the welding wire : C: 0.37%, Si: 0.25%, Mn: 1.44%, Cr: 1.55%, Ni: 3.5%, Mo: 0.68%, Ti: 0.44%, Zr: 0.12%, La: 0.03%, Ce: 0.03% , Pr: 0.01%, Er: 0.01%, Y: 0.04%, Sc: 0.02%, and the rest is iron.

[0042]The welding wire is drawn to Φ2.4mm according to the conventional preparation method.

[0043] The filling rate of the flux cored wire is 25%.

Embodiment 3

[0045] A flux-cored welding wire containing compound rare earth elements suitable for welding 1000MPa ultra-high-strength steel proposed in this embodiment is composed of a flux core and a low-carbon steel strip coated on the outside of the flux core. The flux core includes the following components according to the mass fraction of the welding wire : C: 0.44%, Si: 0.27%, Mn: 1.80%, Cr: 1.2%, Ni: 4.8%, Mo: 0.43%, Ti: 0.6%, Zr: 0.17%, La: 0.04%, Ce: 0.04% , Pr: 0.025%, Er: 0.02%, Y: 0.03%, Sc: 0.015%, and the rest is iron.

[0046] The welding wire is drawn to Φ1.6mm according to the conventional preparation method.

[0047] The filling rate of the flux cored wire is 26%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com