Totally-enclosed self-ventilation traction motor for low-loss and low-noise 100% floor vehicle

A low-floor vehicle, traction motor technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of burning out and insufficiency of three-phase outgoing wires, achieve strong harmonic suppression ability, increase effective iron long, electromagnetic noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

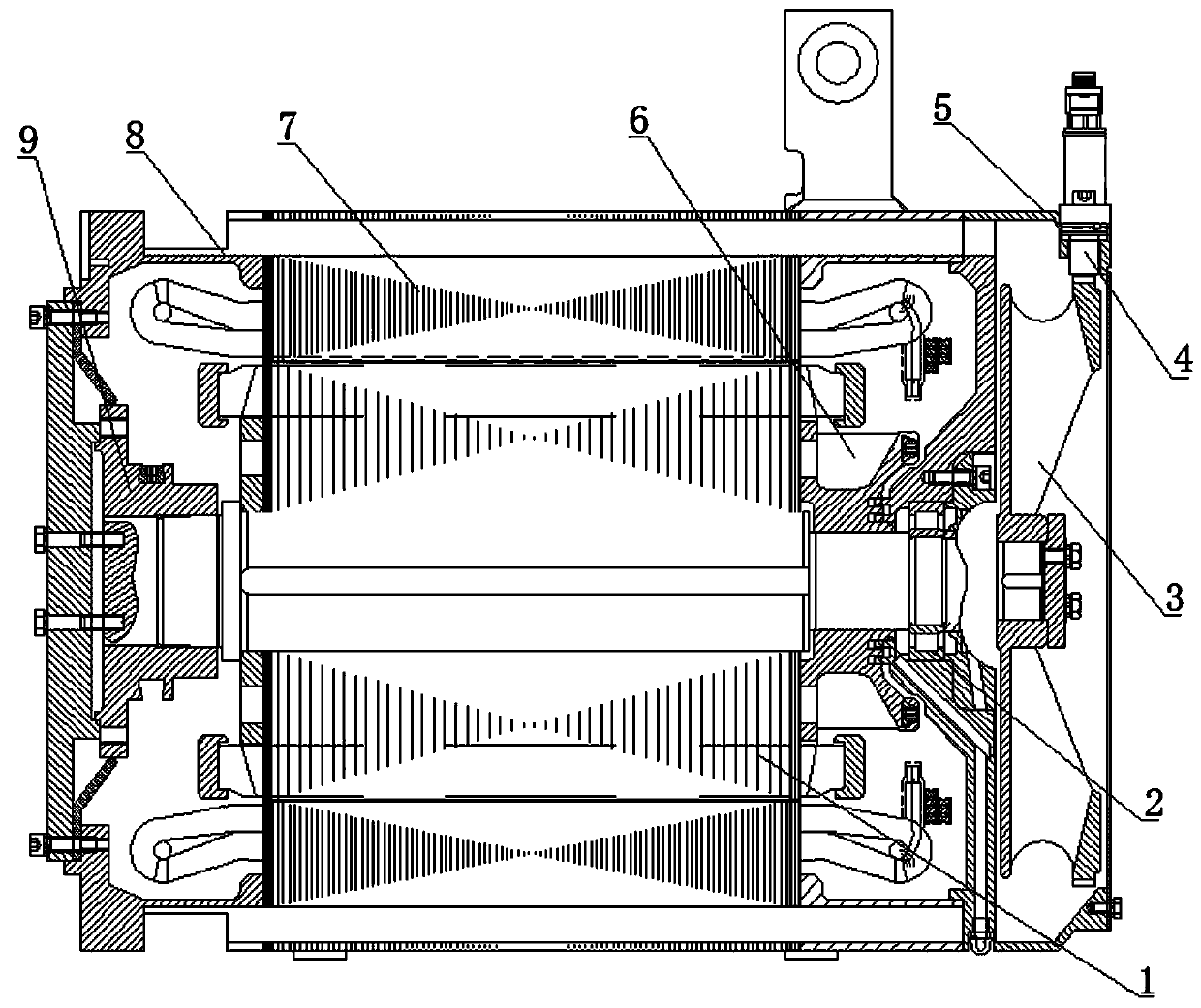

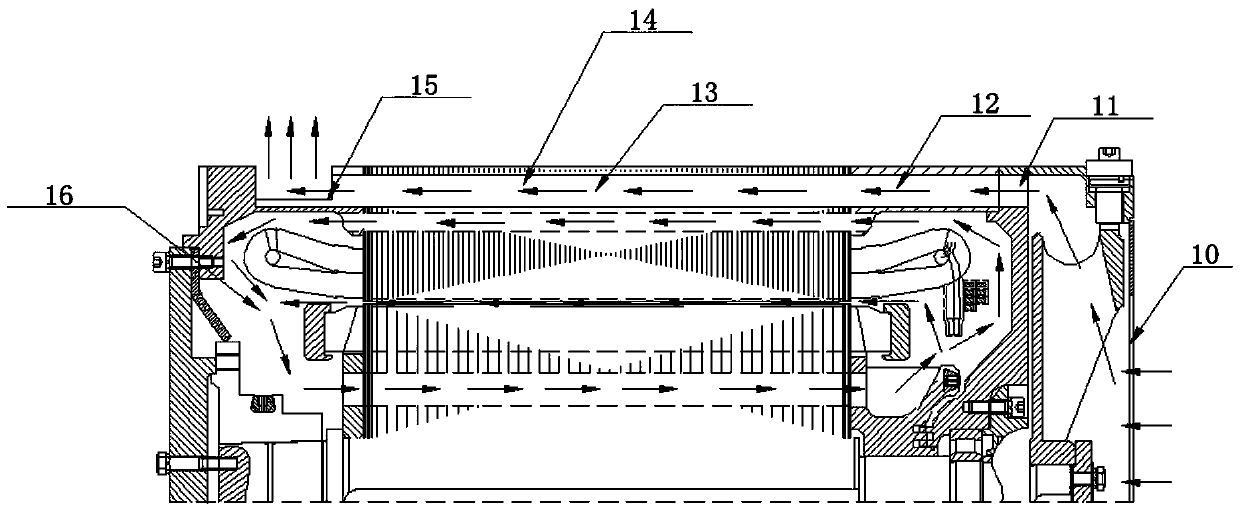

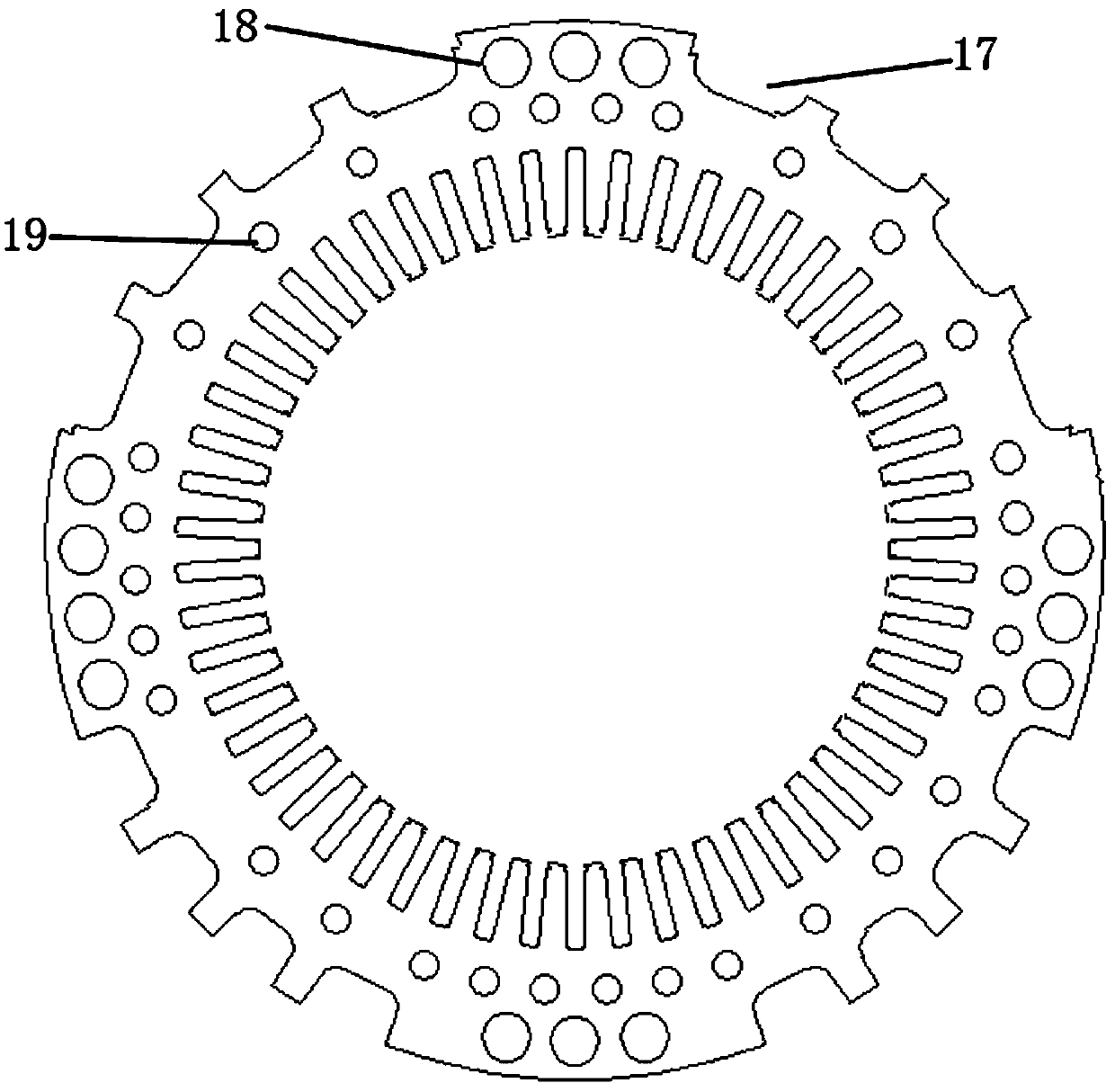

[0042]The motor of the present invention is composed of a stator, a rotor, a non-transmission end cover, a fan, a transmission end cover, a bearing, a shaft coupling and the like. The stator adopts lamination without casing welding structure. The stator core is made of laminated stator punches, and the stator punches are punched from cold-rolled electrical steel sheets with high magnetic permeability and low loss. The stator punching sheet has a complex shape, and is provided with irregular spot facing holes and large and small air holes. The irregular spot facing holes are welded with the external drawing plate to form air ducts and large air holes for rapid heat dissipation, and small air holes for local rapid heat dissipation. There is a stator coil inside the stator, the stator coil is made of film-welded wire, the inter-turn insulation is made of welded film, the main insulation is made of glass cloth reinforced mica tape and polyimide film, when the coil nose is wound L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com