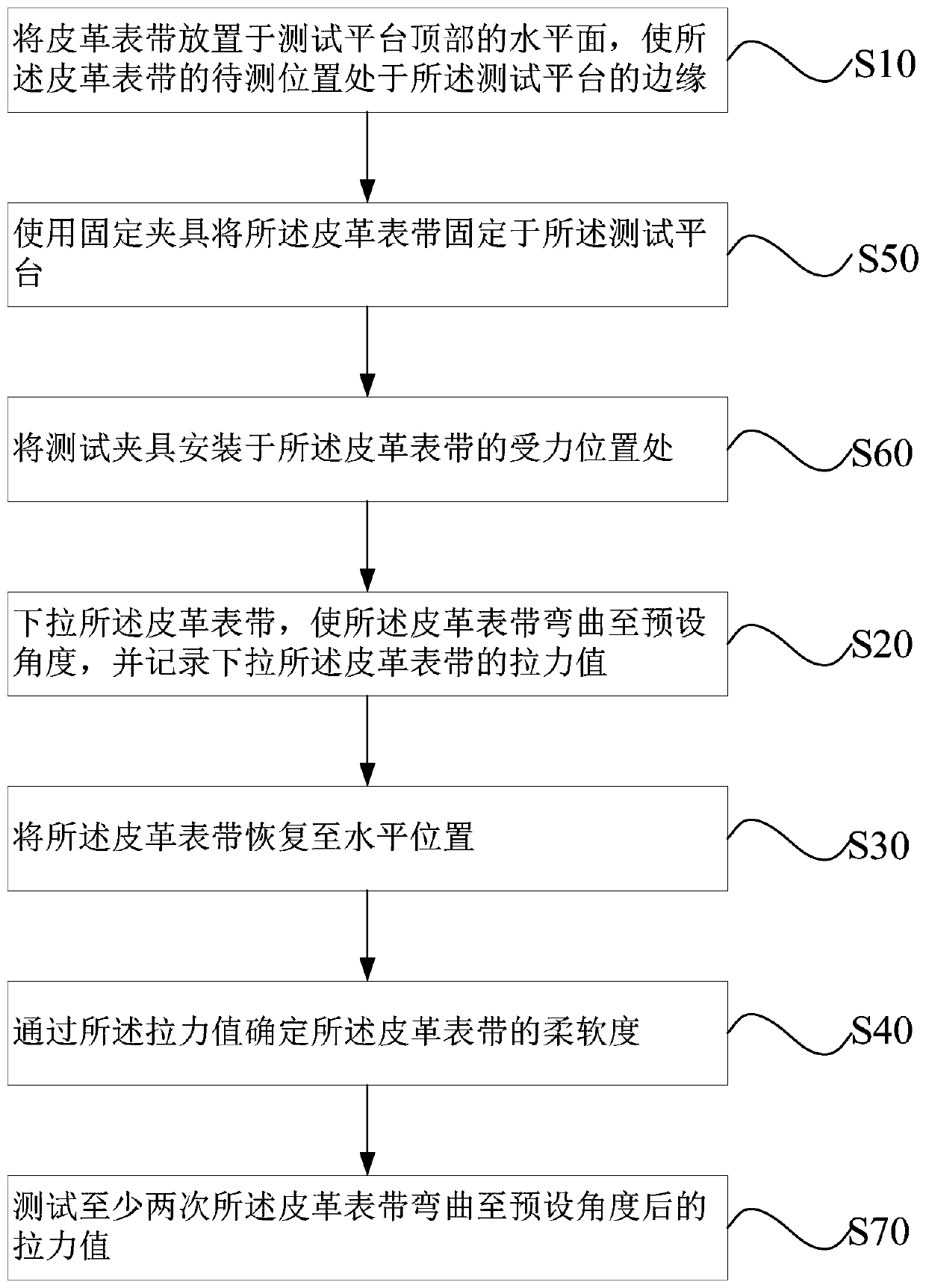

Method for detecting softness of leather watchband

A detection method and softness technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of undetectable softness of leather straps, and achieve reliable detection and comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] 1. Sample

[0094] Model 5611 leather strap 110×100PCS (20mm wide and 5mm thick).

[0095] 2. Test steps

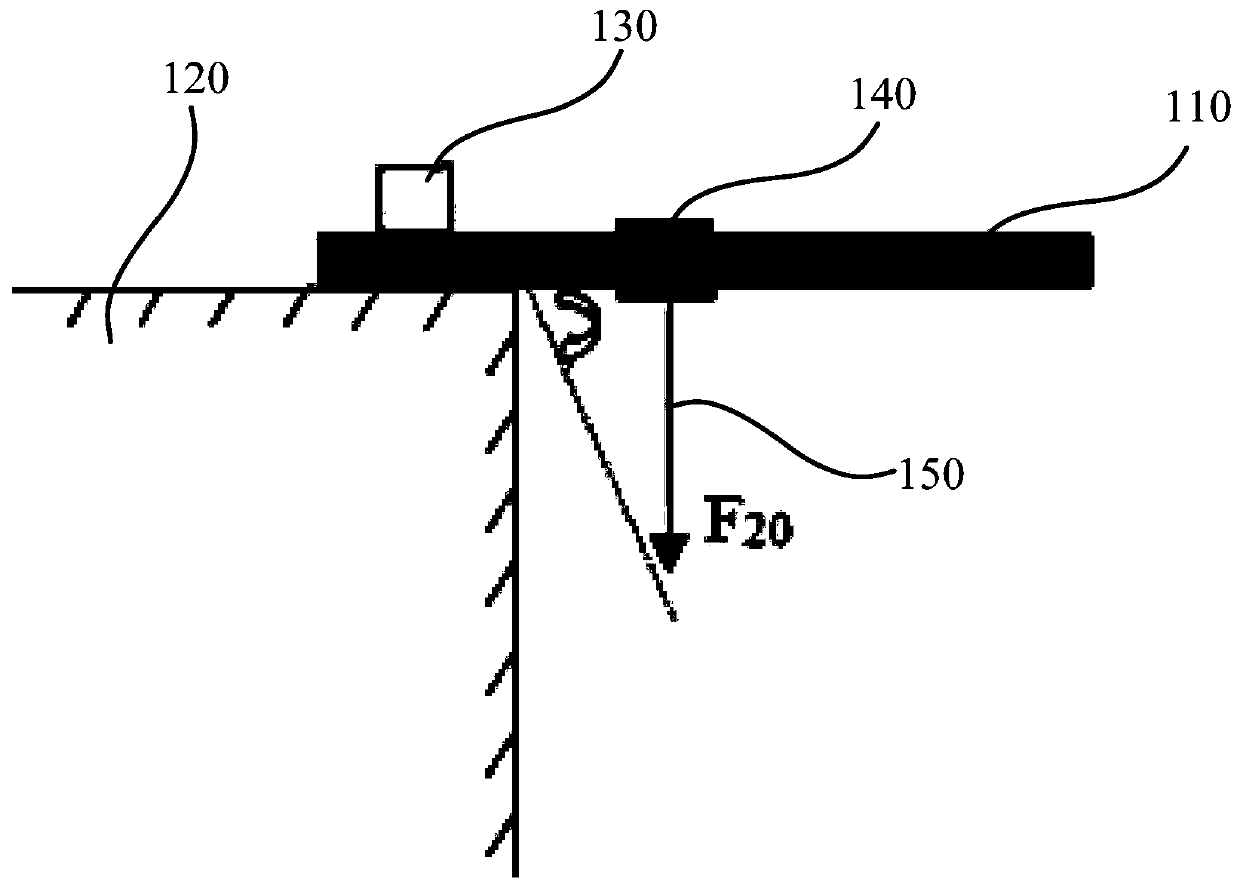

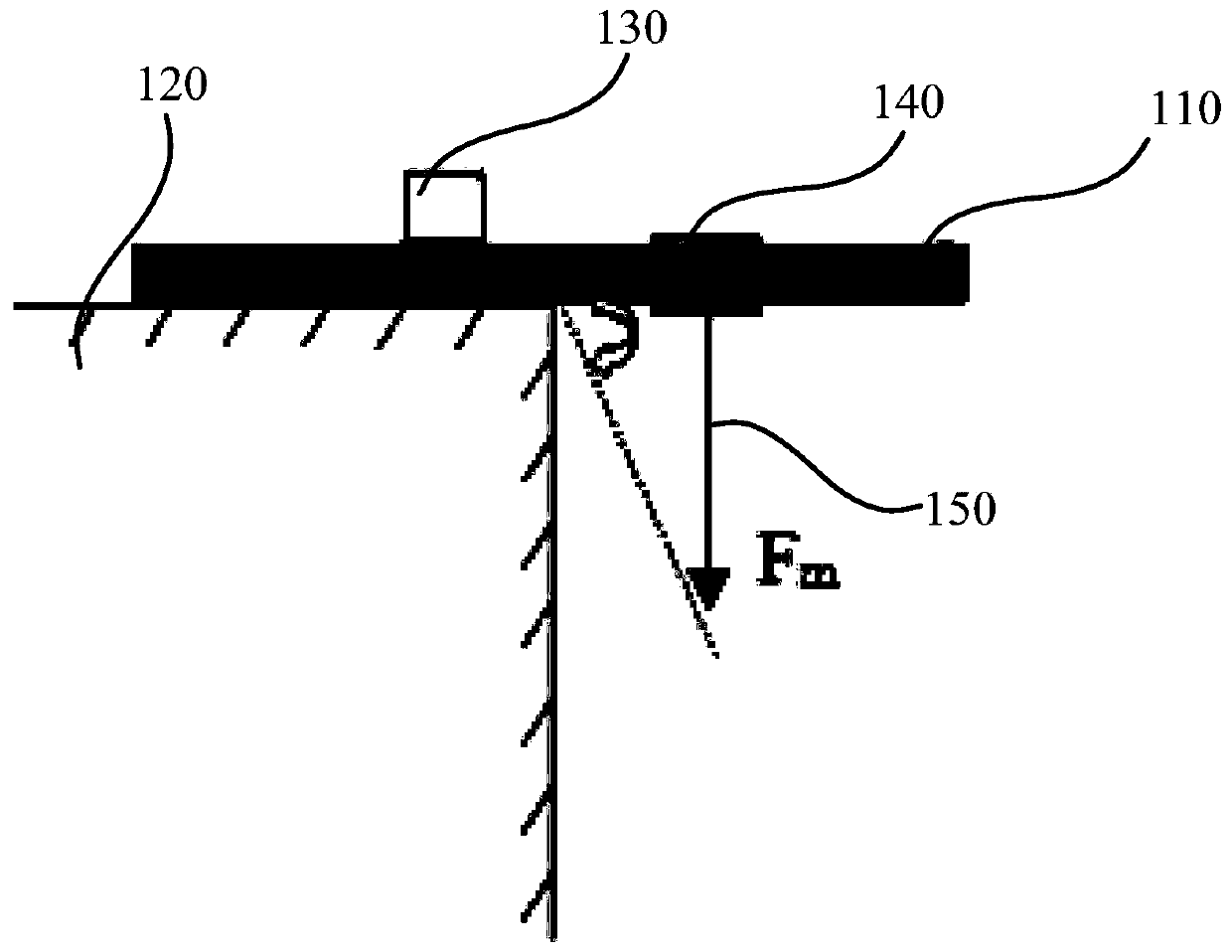

[0096] (1) Softness test at 20 mm from the end of the shaft hole: fix the leather strap 110 on the horizontal plane of the test platform 120 so that the short side shaft hole end of the leather strap 110 is 20 mm from the edge of the test platform 120, and then use the fixing fixture 130 Fix it on the test platform 120, install the test fixture 140 on the leather strap 110 at the force-bearing position of 120 (10 ± 1) mm away from the test platform, and then connect the tension meter 150 to the test fixture 140, and pull down the tension The gauge 150 makes the leather strap 110 bend to 30°~60°, and record the force value of the tension gauge 150 at this time (referred to as F 20 ), then restore the leather strap 110 to a horizontal position, and then measure the tension value bent to 30°-60° twice;

[0097] (2) Middle part softness test: the leather strap 110 i...

Embodiment 2

[0101] 1. Sample

[0102] The leather strap of the 5718 model is 110×100PCS (18mm wide and 3mm thick).

[0103] 2. Test steps

[0104] (1) Softness test at 20 mm from the end of the shaft hole: fix the leather strap 110 on the horizontal plane of the test platform 120 so that the short side shaft hole end of the leather strap 110 is 20 mm from the edge of the test platform 120, and then use the fixing fixture 130 Fix it on the test platform 120, install the test fixture 140 on the leather strap 110 at the force-bearing position of 120 (10 ± 1) mm away from the test platform, and then connect the tension meter 150 to the test fixture 140, and pull down the tension The gauge 150 makes the leather strap 110 bend to 30°~60°, and record the force value of the tension gauge 150 at this time (referred to as F 20 ), then restore the leather strap 110 to a horizontal position, and then measure the tension value bent to 30°-60° twice;

[0105] (2) Middle part softness test: the leath...

Embodiment 3

[0109] (1) Sample

[0110] Model 517770 leather strap 110×100PCS (12mm wide and 2mm thick).

[0111] 2. Test steps

[0112] (1) Softness test at 20 mm from the end of the shaft hole: fix the leather strap 110 on the horizontal plane of the test platform 120 so that the short side shaft hole end of the leather strap 110 is 20 mm from the edge of the test platform 120, and then use the fixing fixture 130 Fix it on the test platform 120, install the test fixture 140 on the leather strap 110 at the force-bearing position of 120 (10 ± 1) mm away from the test platform, and then connect the tension meter 150 to the test fixture 140, and pull down the tension The gauge 150 makes the leather strap 110 bend to 30°~60°, and record the force value of the tension gauge 150 at this time (referred to as F 20 ), then restore the leather strap 110 to a horizontal position, and then measure the tension value bent to 30°-60° twice;

[0113] (2) Middle part softness test: the leather strap 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com