Method and device for predicting sound insulation performance of automobile metal plate part assembly with plug

A performance prediction, sheet metal technology, applied in the field of sound insulation performance prediction method and prediction device of automobile sheet metal parts assembly, can solve the problems of inconvenient large-scale use, high cost, long cycle, etc., to avoid high cost and improve Efficiency, fast and accurate prediction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

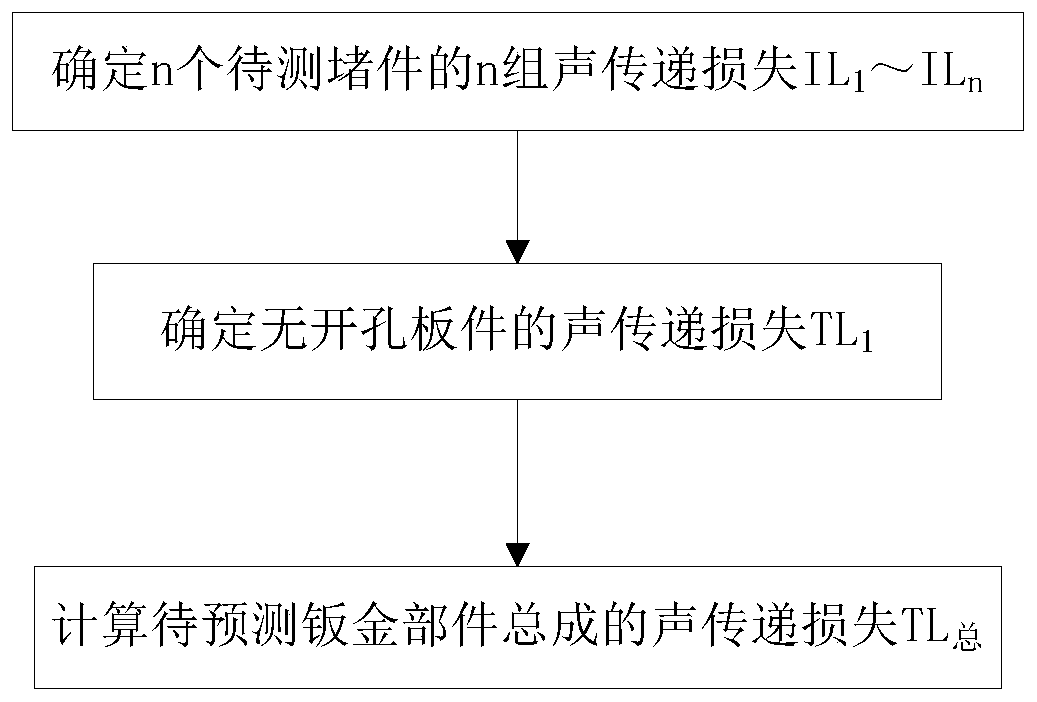

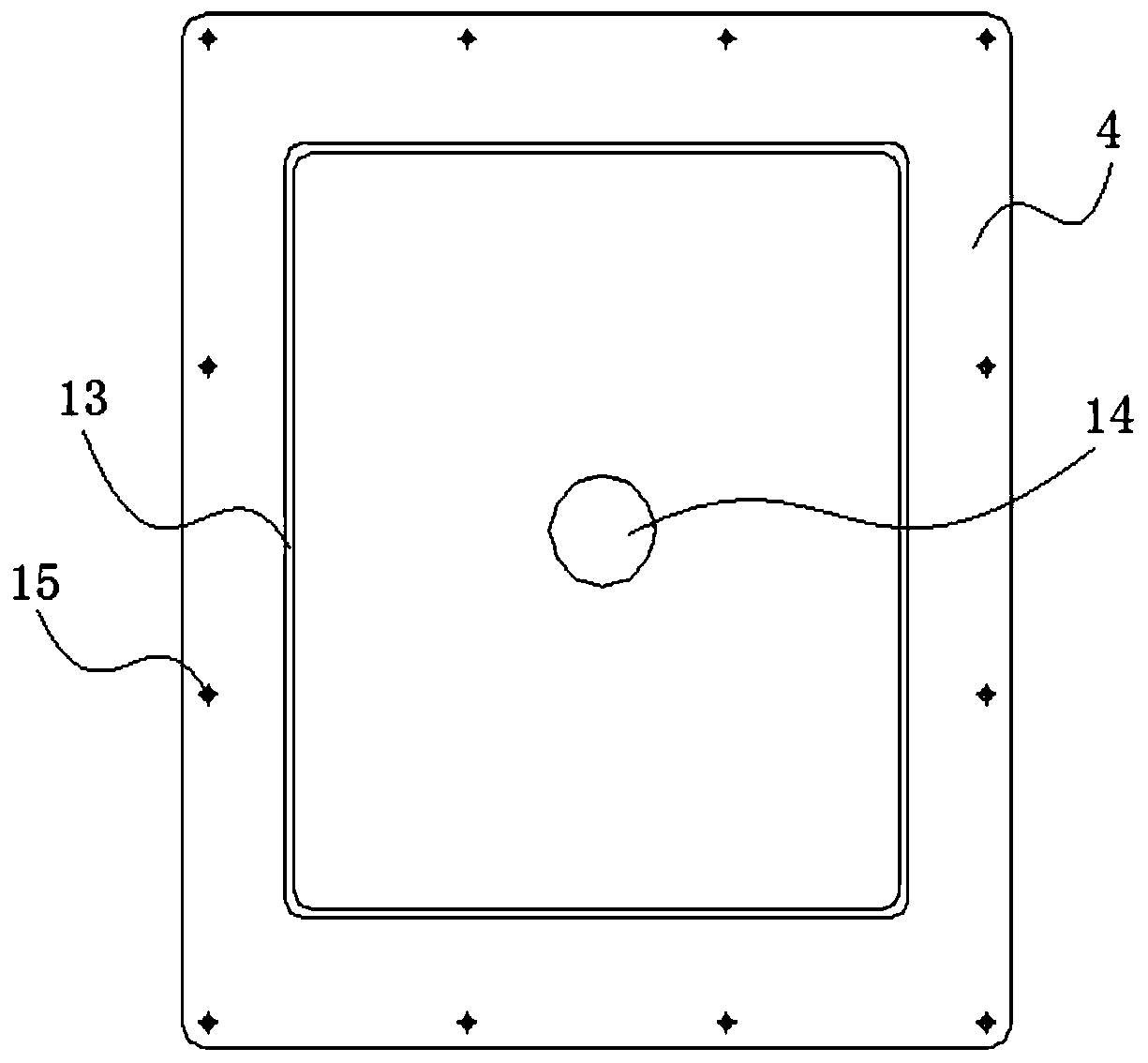

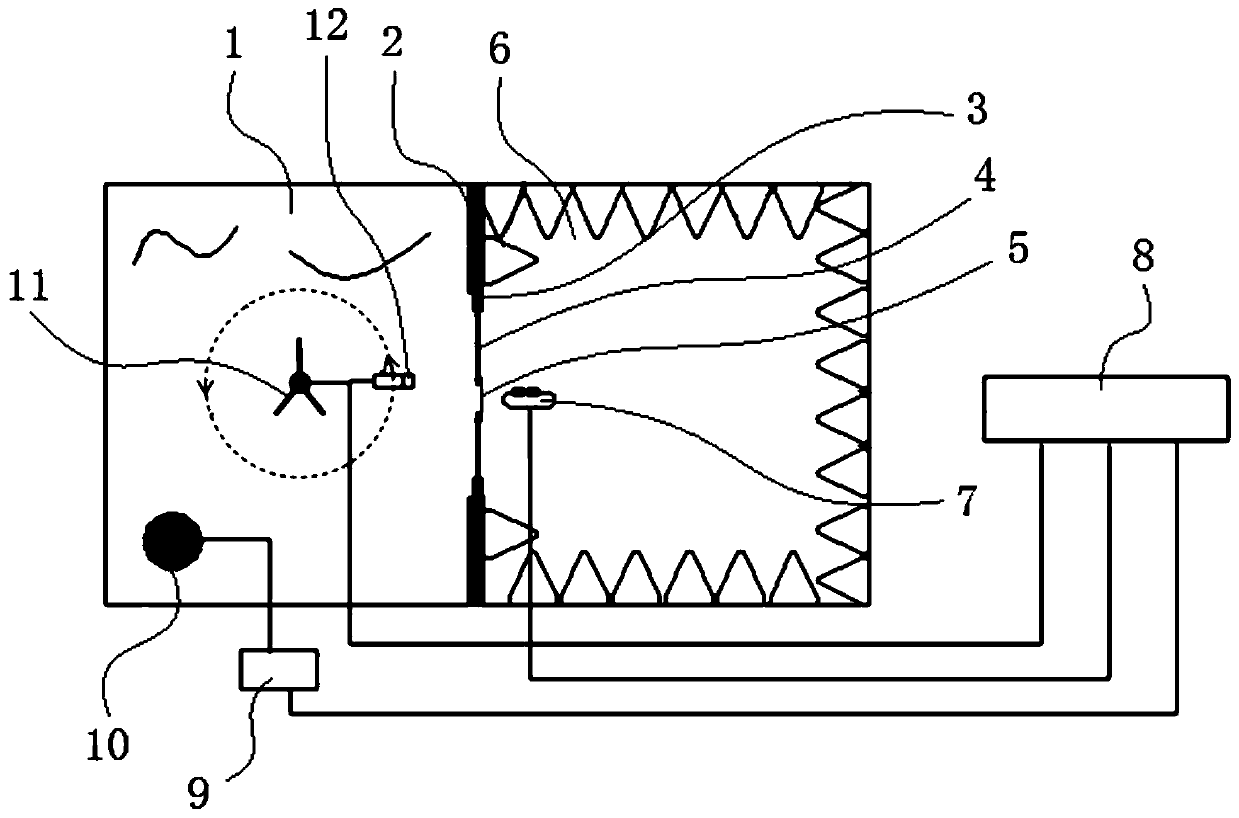

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 2 , image 3 The sound insulation performance prediction equipment for automobile sheet metal parts assembly with blocking parts shown, including tester 8, reverberation chamber 1, anechoic chamber 6, plate fixture 3, plate without openings, m different types The block to be tested, m pieces of perforated plates, the sound insulation wall 2 between the reverberation chamber 1 and the anechoic chamber 6, the spherical sound source 10 and the microphone 12 in the reverberation chamber 1 and the anechoic chamber Sound intensity probe 7 within 6. The spherical sound source 10 is placed in the lower left corner of the reverberation chamber 1 . The center of the ground of the reverberation chamber 1 is placed with a rotating bracket 11, the height of the rotating bracket 11 is 1.5m, the length of the connecting rod of the rotating bracket 11 is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com