Mechanical seal end face for nuclear power medium-pressure safety injection pump

A technology for mechanical seals and pumps, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of increased leakage of mechanical seals, achieve the effects of enhanced lubricity, increased liquid film thickness, and reduced leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

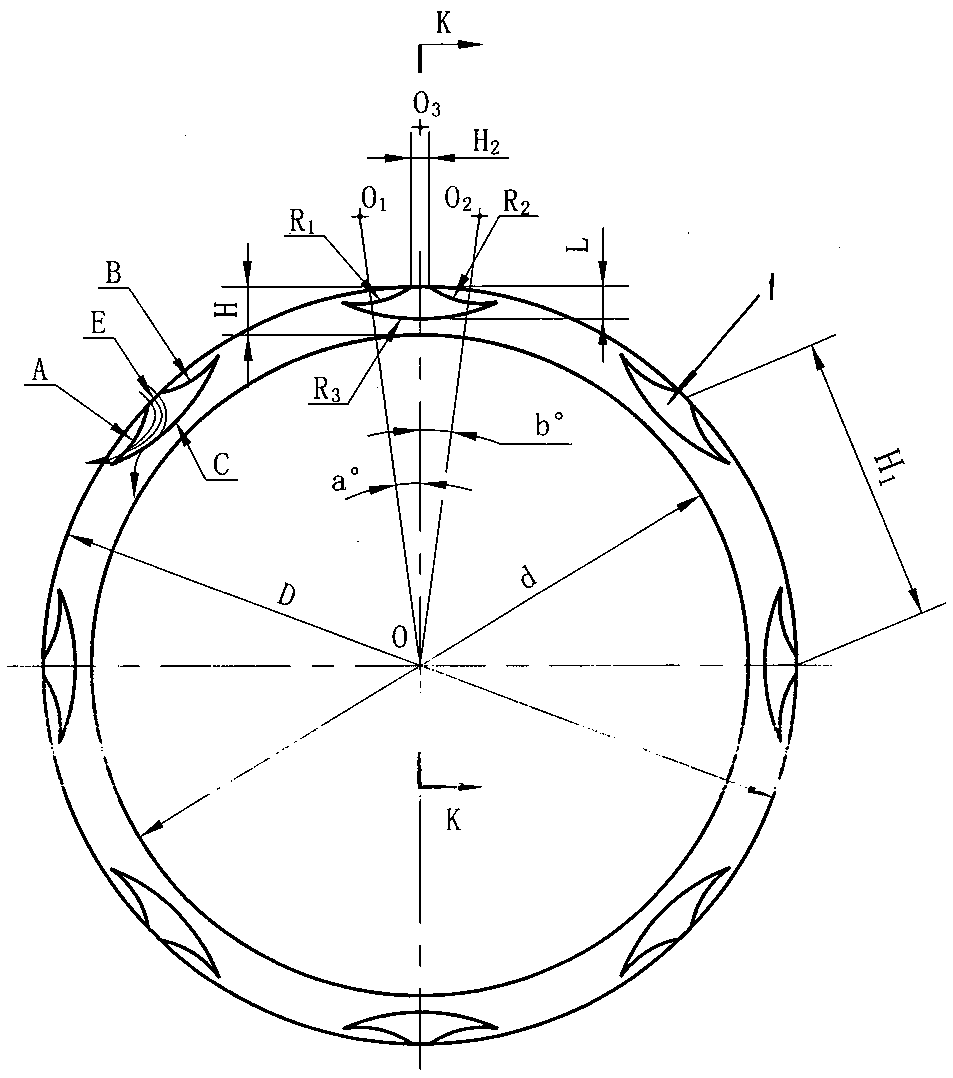

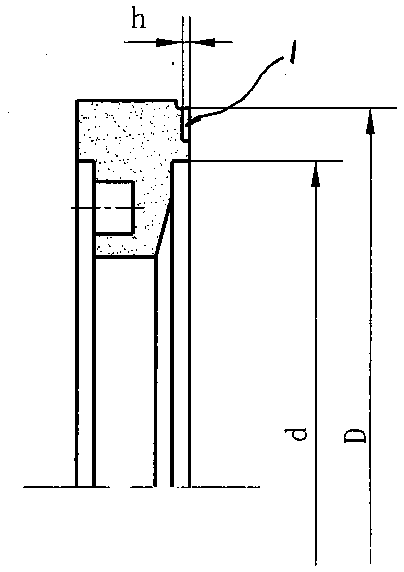

[0028] Technical parameters: the inner diameter of the friction end face d=106mm, the outer diameter of the friction end face D=114mm, the width of the end face H=4mm; the inner arc edge C radius R 3 =25mm; Radius R of left outer arc edge A 1 Radius R with the right outer arc edge B 2 :R 1 =R 2 =10mm; notch E width H 2 ≈3.5mm; the distance between the arc top of the center line of the inner arc side C and the outer circle of the friction end face is L=2.8mm; the angle a between the center of the left outer arc side A and the center b of the right outer arc side B: a= b=6º; the distance H between the centers of two adjacent arc-shaped dynamic pressure grooves 1 1 =25mm; depth of dynamic pressure groove h=6μm; number of dynamic pressure grooves n=14.

[0029] Working conditions: 180°C water; pressure 0.5MPa; speed 1500r / min; running time: 100 hours.

[0030] Test method: Simulate the above-mentioned working conditions on the test bench to conduct an operation test, observe...

Embodiment 2

[0033] Technical parameters: the inner diameter of the friction end face d=106mm, the outer diameter of the friction end face D=114mm, the width of the end face H=4mm; the inner arc edge C radius R 3 =20mm; Radius R of left outer arc edge A 1 Radius R with the right outer arc edge B 2 :R 1 =R 2 =8mm; notch E width H 2 ≈3mm; the distance between the arc top of the center line of the inner arc side C and the outer circle of the friction end face is L=2.8mm; the angle a between the center of the left outer arc side A and the center b of the right outer arc side B: a=b =6.5º; the distance H between the centers of two adjacent arc-shaped dynamic pressure grooves 1 1 =20mm; depth of dynamic pressure groove h=5μm; number of dynamic pressure grooves n=18.

[0034] Working conditions: 180°C water; pressure 2MPa; speed 3000r / min; running time: 100 hours.

[0035] Test method: Simulate the above-mentioned working conditions on the test bench to conduct an operation test, observe th...

Embodiment 3

[0038] Technical parameters: the inner diameter of the friction end face d=106mm, the outer diameter of the friction end face D=114mm, the width of the end face H=4mm; the inner arc edge C radius R 3 =22mm; Radius R of left outer arc edge A 1 Radius R with the right outer arc edge B 2 :R 1 =R 2 =9mm; notch E width H 2 ≈3mm; the distance between the arc top of the center line of the inner arc side C and the outer circle of the friction end face is L=2.8mm; the angle a between the center of the left outer arc side A and the center b of the right outer arc side B: a=b =6º; the distance H between the centers of two adjacent arc-shaped dynamic pressure grooves 1 1 =22mm; depth of dynamic pressure groove h=8μm; number of dynamic pressure grooves n=16.

[0039] Working conditions: 180°C water; pressure 6MPa; speed 1000r / min; running time: 100 hours.

[0040] Test method: Simulate the above-mentioned working conditions on the test bench to conduct an operation test, observe the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com