Speed reducer

A technology of reducer and connector, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc. It can solve the problems of insufficient running precision, large vibration amplitude, frequent maintenance, etc., and achieve high precision of zero-gap transmission, The effect of good practical performance and high stability torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

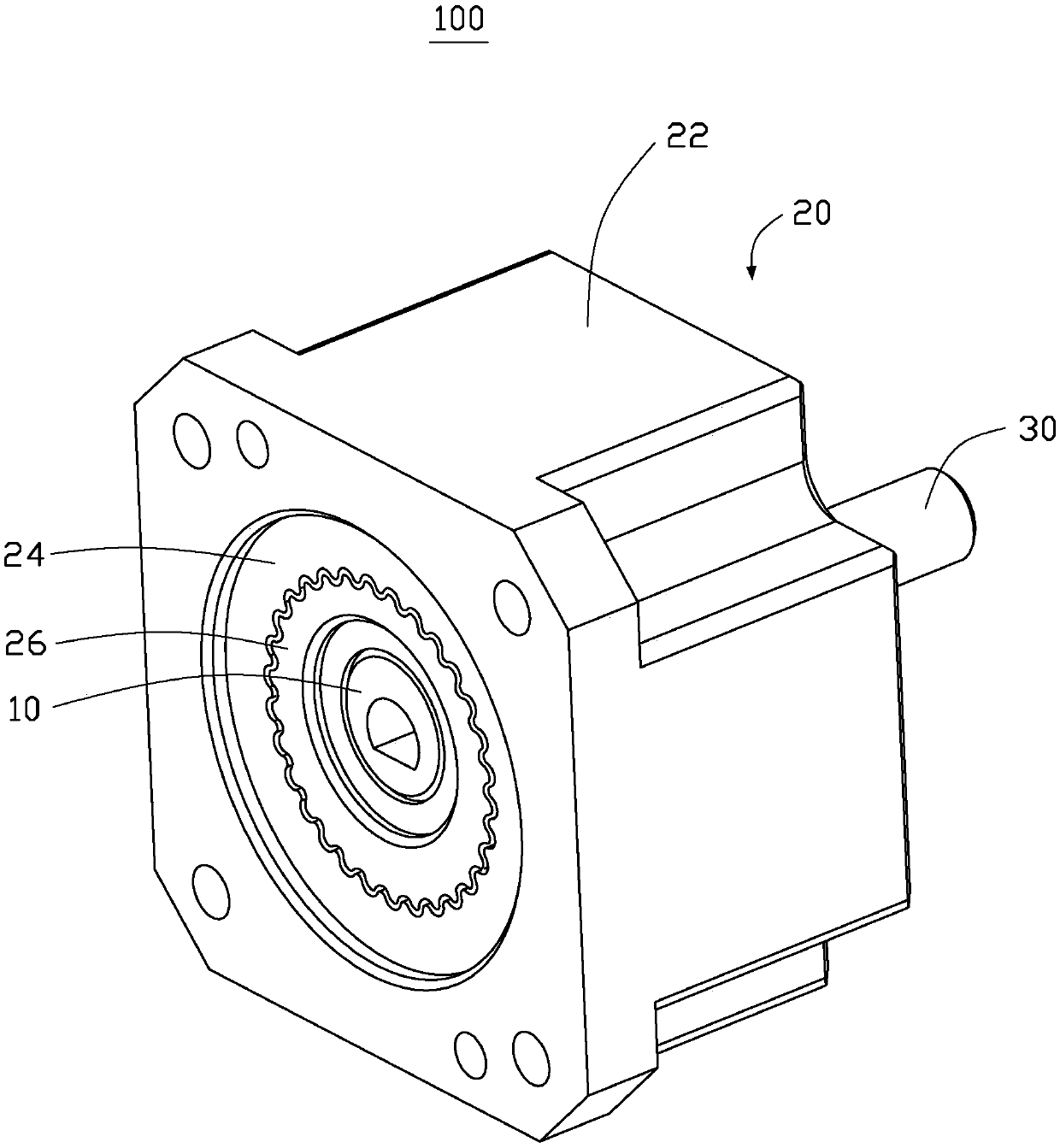

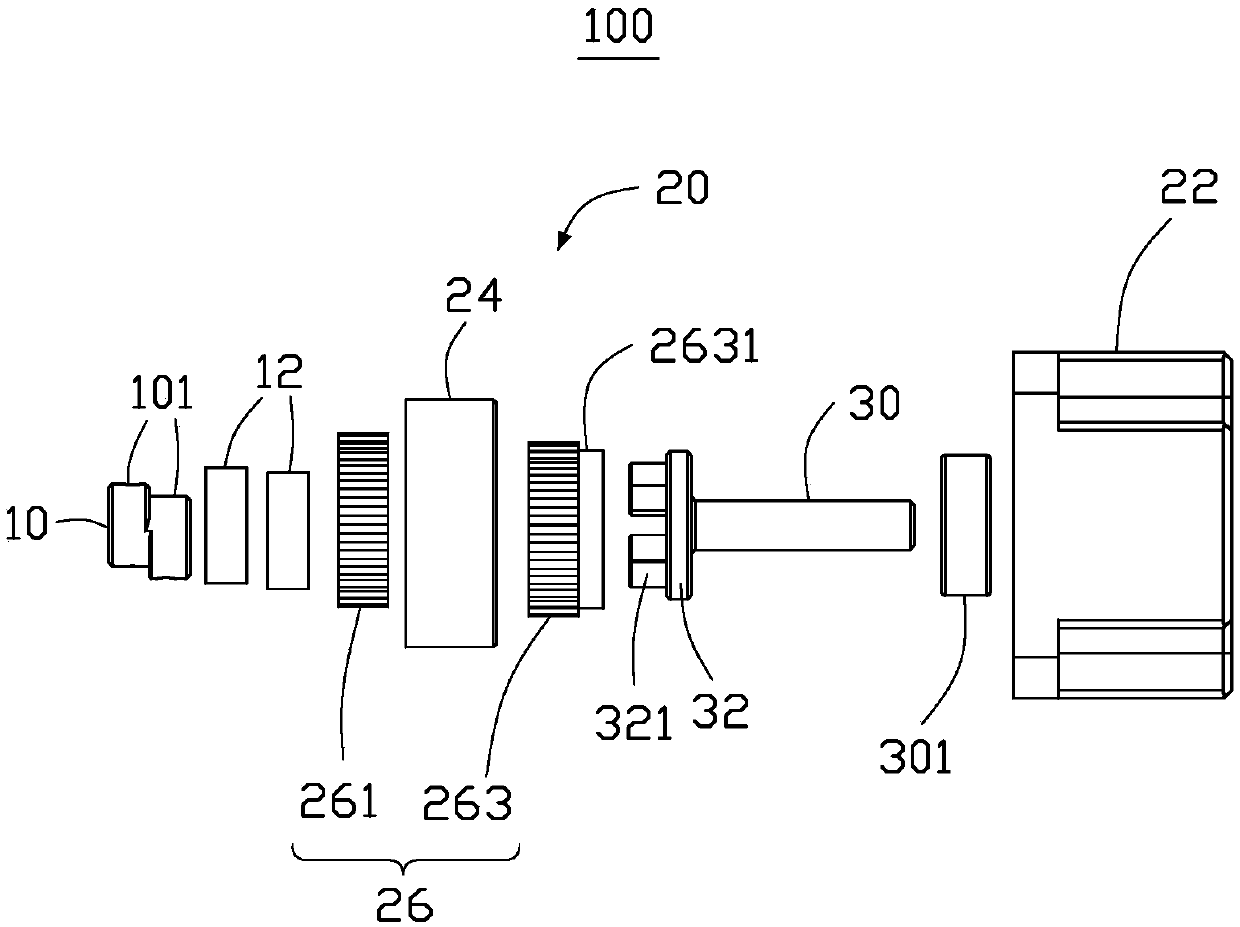

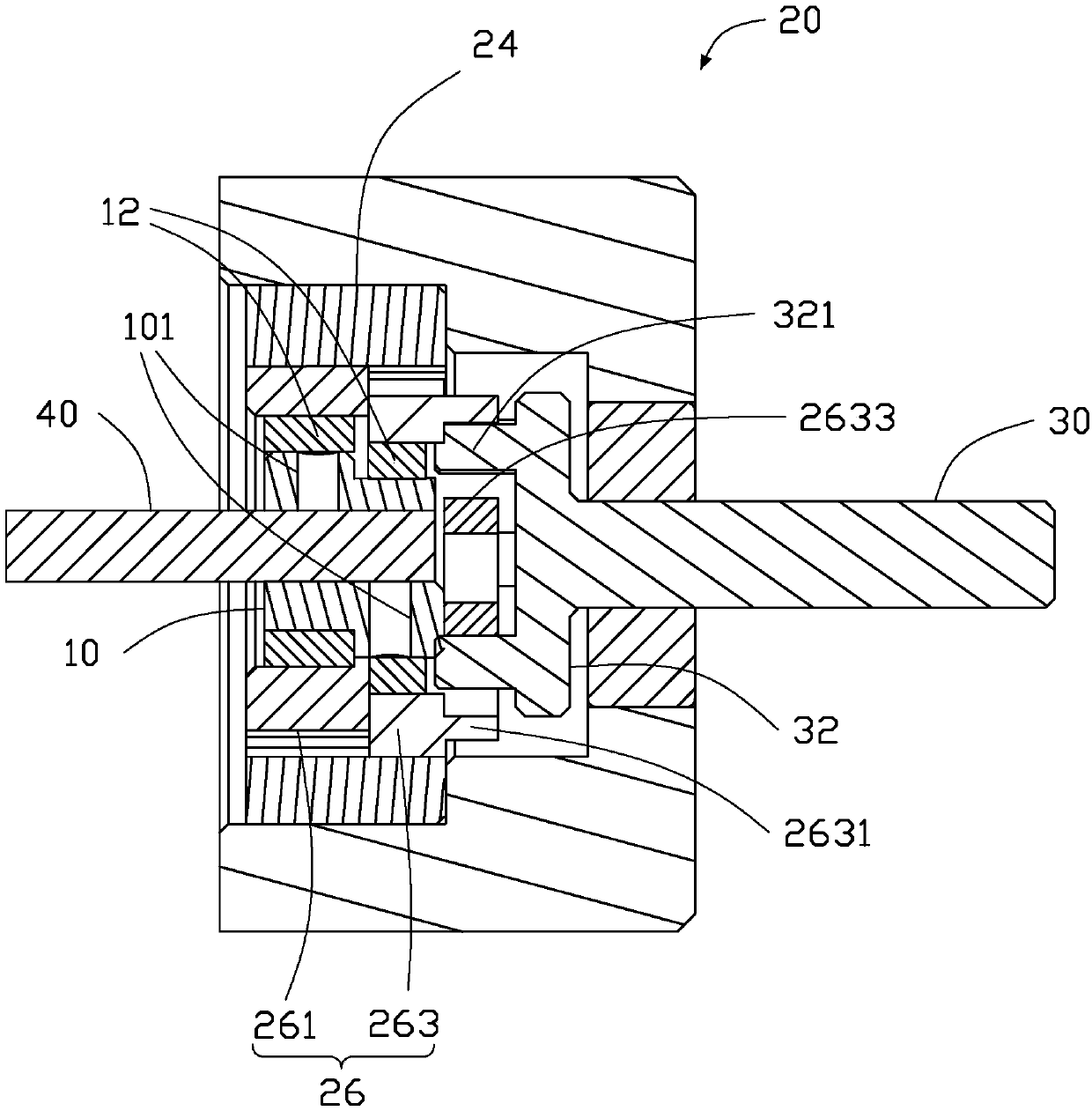

[0032] see figure 1 and figure 2 , figure 1 It is a three-dimensional schematic view of a specific embodiment of the reducer of the present invention. figure 2 yes figure 1 Disassembled three-dimensional schematic diagram of the reducer. figure 1 The reducer 100 described in the above includes an input shaft 10, a gear unit 20, and an output shaft 30. The input shaft 10 and the output shaft 30 are respectively located on both sides of the gear unit 20, and together form a small volume and a compact structure. The reducer 100. see again figure 2 , the input shaft 10 is an eccentric shaft, and the eccentric shaft is connected with the gear unit 20 . The gear unit 20 includes a housing 22, an external gear 24 and at least two internal gears 26, the external gear 24 is arranged in the housing 22, and the external gear 24 is internally connected to the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com