Speed reduction device for baby carrier

A deceleration device and stroller technology, which is applied in the field of strollers, can solve the problems of high noise of the deceleration mechanism, complex structure of the reducer, and excessive useless work of the motor, and achieve the effects of increasing output power, facilitating high-efficiency energy transmission, and large transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

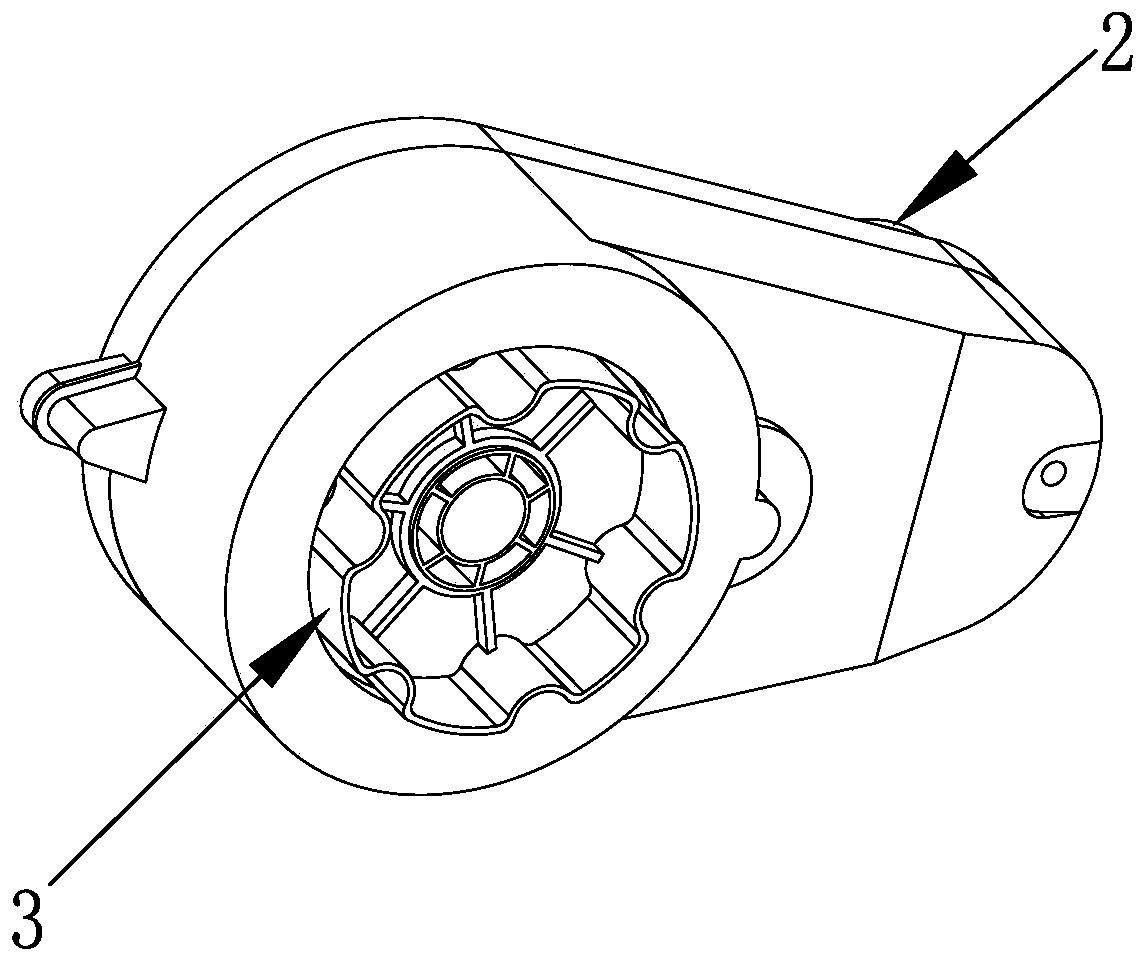

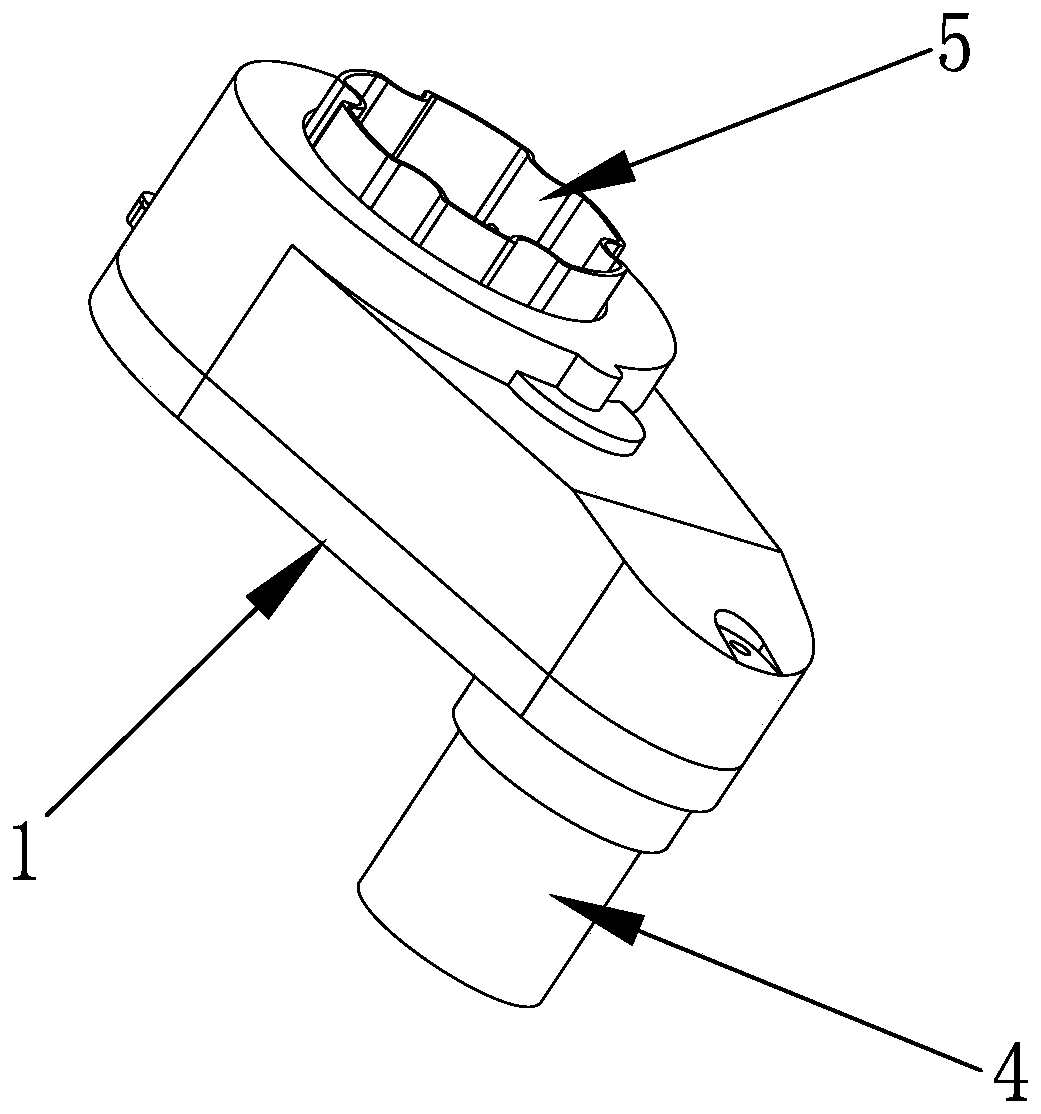

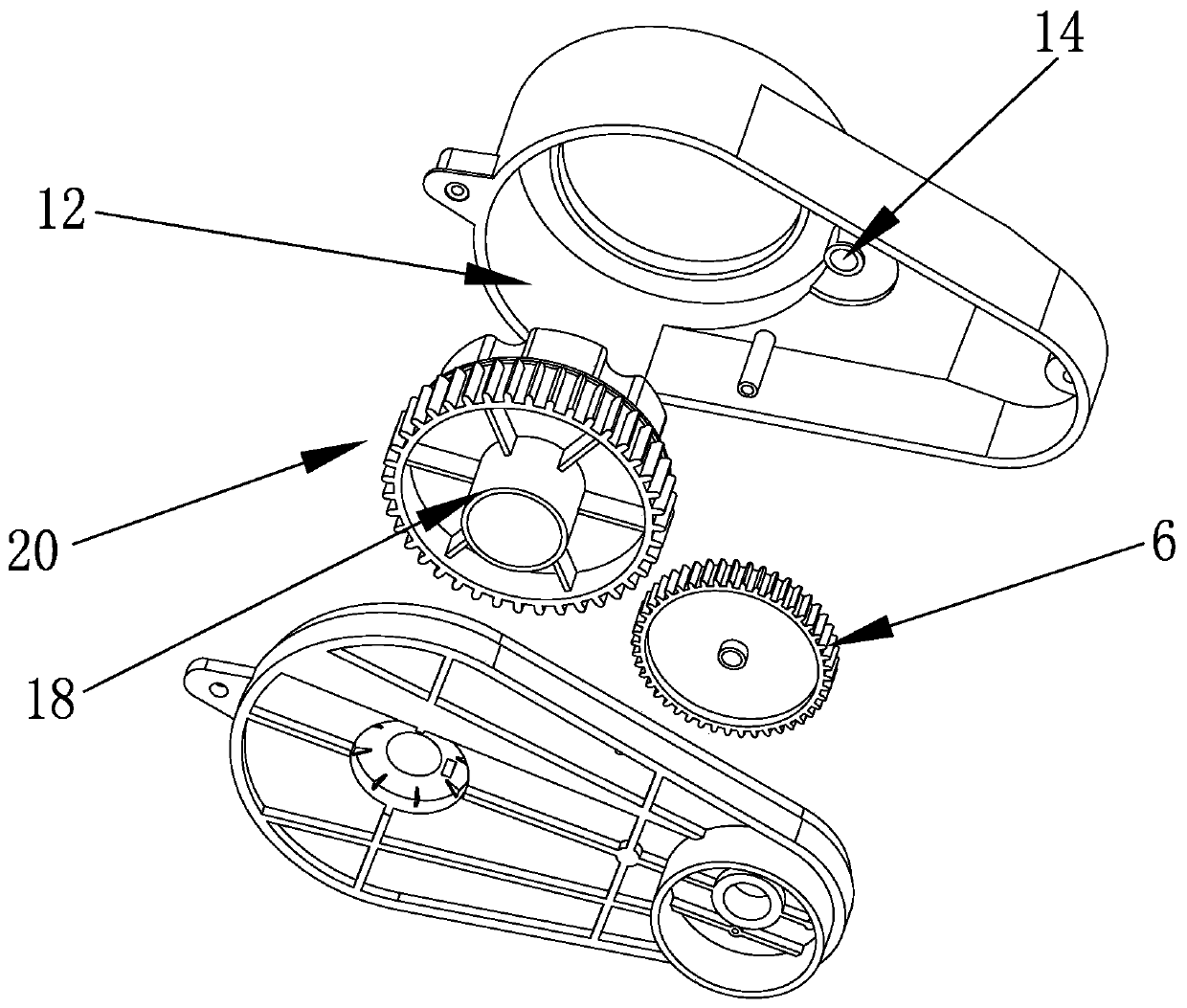

[0034] Such as Figure 1-4 As shown, a speed reduction device for a stroller provided in this embodiment includes a speed reduction device body 1, on which an input end 2 and an output end 3 are provided; the input end 2 is equipped with a motor 4, and the output end 3 is provided with an output interface 5. The deceleration device body 1 includes a base 10, a housing 11 assembled on the base 10, and a cavity 12 for accommodating the deceleration mechanism 20 is formed between the base 10 and the housing 11; In the mechanism, the driving gear drives the output gear to rotate through the pinion, realizing zero-backlash transmission and high-precision, high-stability torque transmission, achieving good practical performance.

[0035] Specifically, the reduction mechanism 20 includes a driving gear 6 and an output gear 7; the driving gear 6 is fixed with a pinion 8, the pinion 8 is meshed with the output gear 7, the motor 4 is connected with the driving gear 6, and the driving ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com