Ratchet wheel with protection and identification layers and manufacturing method thereof

A ratchet wheel and manufacturing method technology, applied in the field of a ratchet wheel with a protective and identification layer and its manufacturing method, can solve the problems of reduced meshing force of the ratchet wheel assembly, easy to wear, and the coating layer falls off, and achieves improved wear resistance and is not easy to fall off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

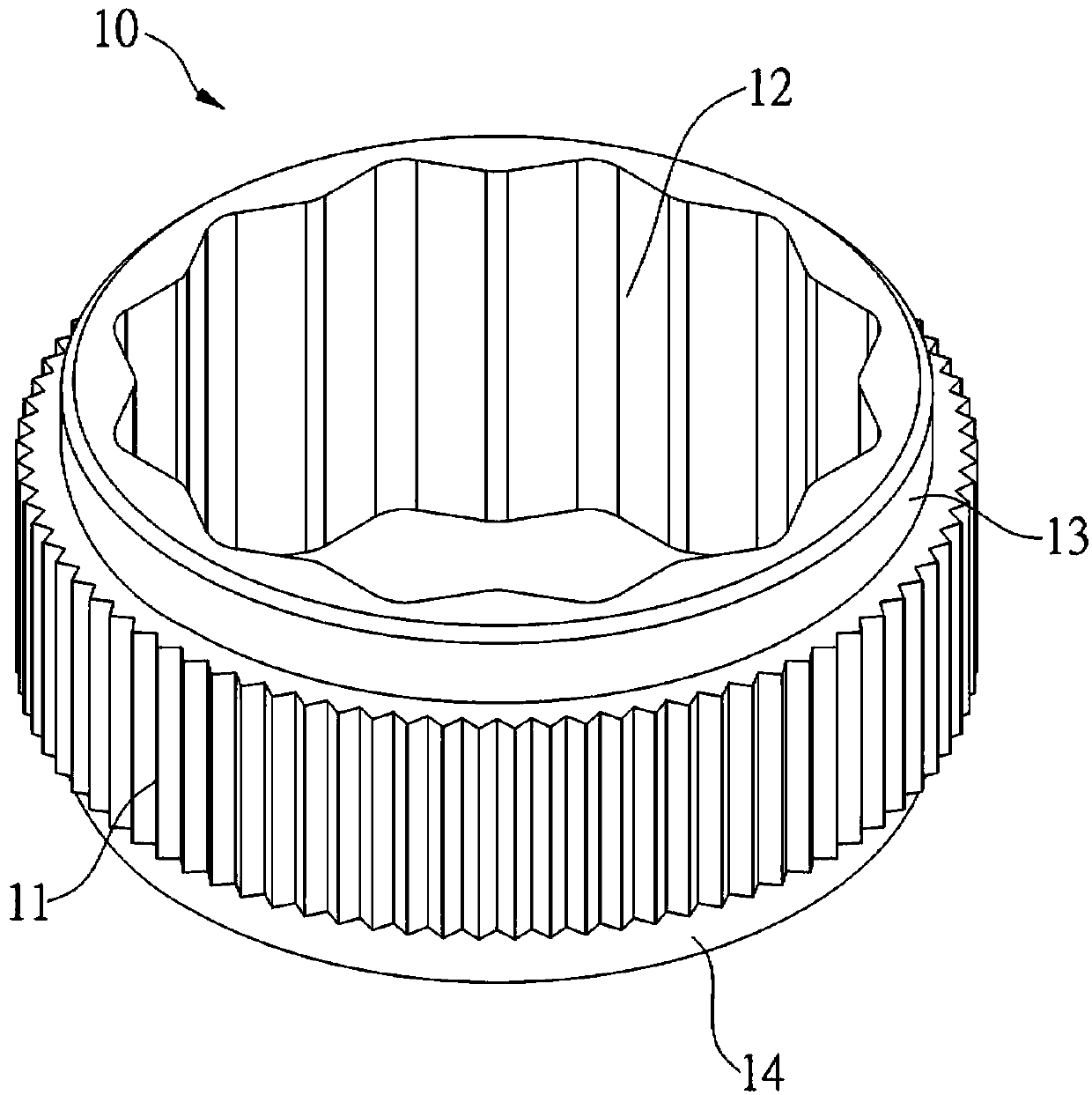

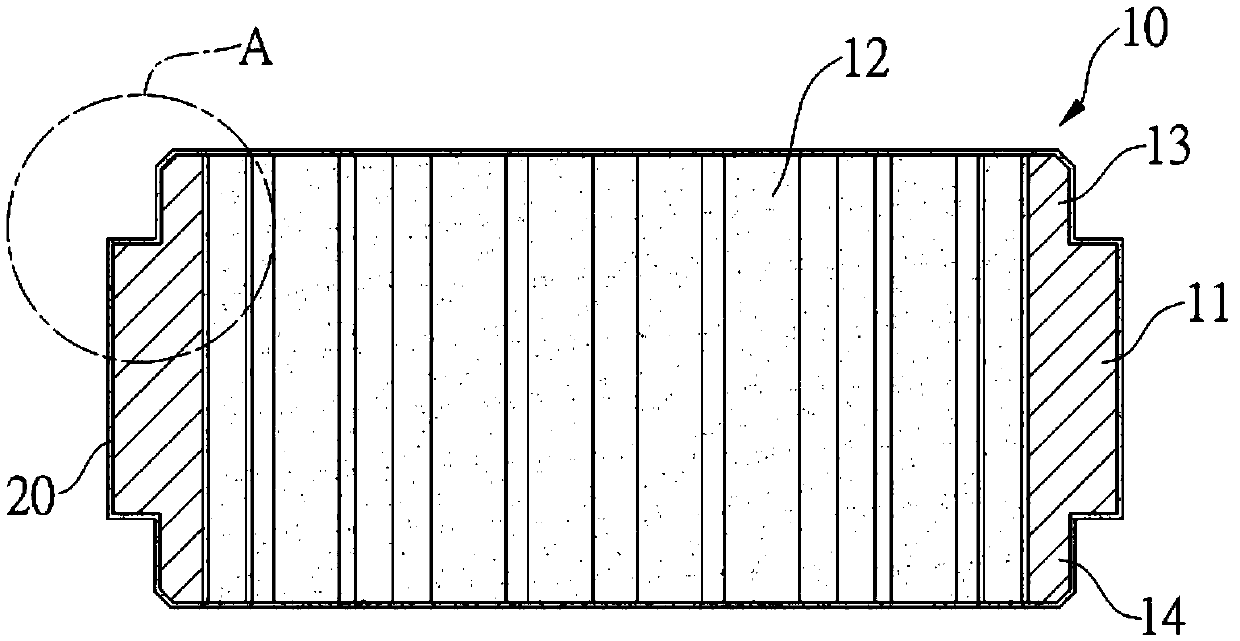

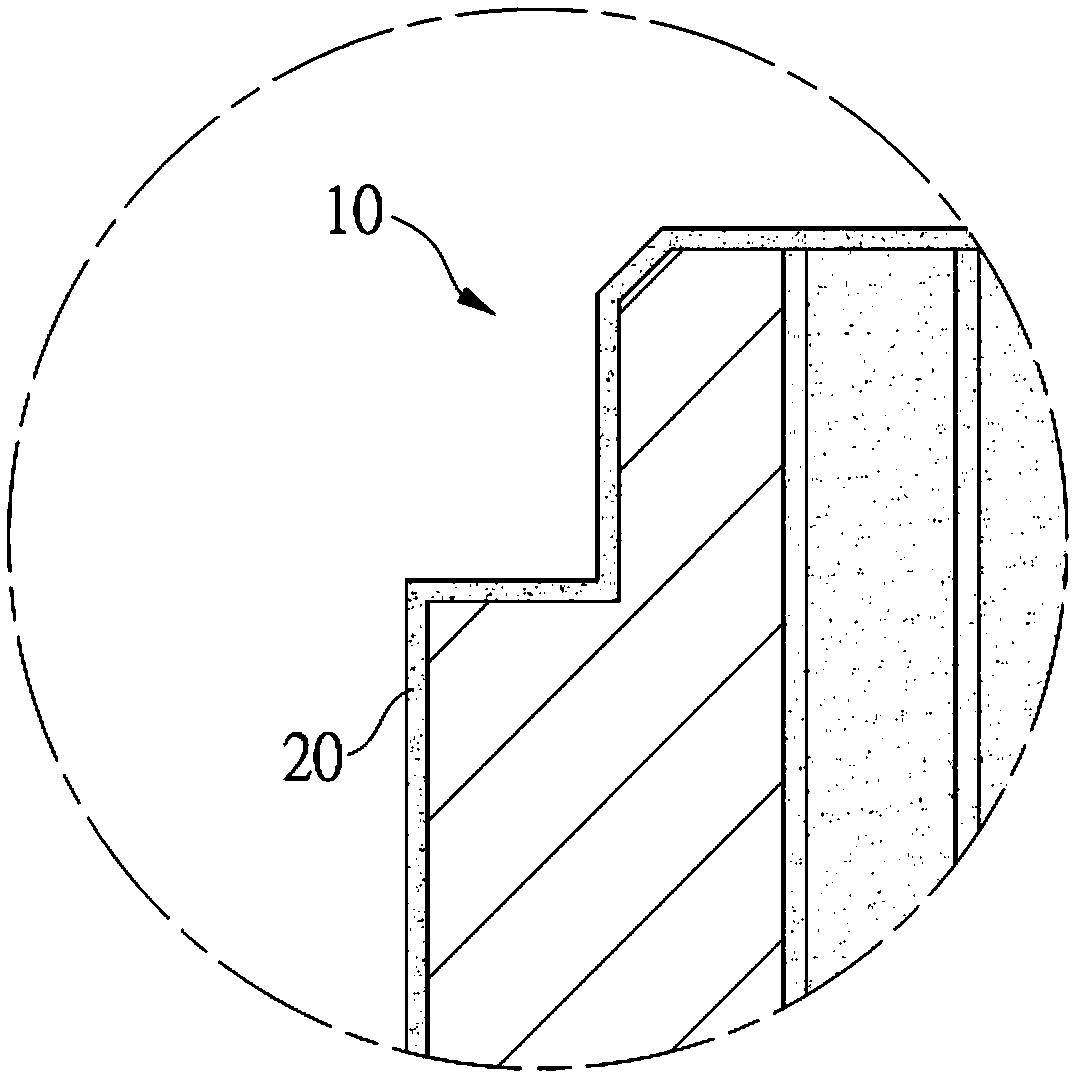

[0045] Such as figure 1 , figure 2 , Figure 5 , the ratchet manufacturing method with identification structure of the present invention, through this manufacturing method, a comprehensive protective coating 20 and a partial identification coating 40 are formed on the surface of the ratchet.

[0046] Such as figure 1 , the ratchet wheel 10 includes: an outer ring surface 11, which is a ratchet tooth surface; an inner ring surface 12, which is a polygonal fitting surface; a first end 13 and a second end 14, respectively connected to the outer ring surface 11 and the two ends of the inner ring surface 12.

[0047] The manufacturing method includes: step 1, electroplating the above-mentioned ratchet 10 for the first time, and forming a ring on the entire surfaces of the outer ring surface 11, the inner ring face 12, the first end 13, and the second end 14 of the ratchet wheel 10. Protective coating 20 (such as figure 2 , image 3 ); Step 2, after the ratchet 10 is taken o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com