Workpiece charging and discharging auxiliary device for large-scale special-shaped workpiece

A technology of special-shaped workpieces and auxiliary devices, which is applied in the direction of spraying devices, transportation and packaging, conveyors, etc., can solve the problems of threats to the safety of operators, high labor intensity of workers, and time-consuming and labor-intensive operations, and achieve high cost performance, simple structure, and improved The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

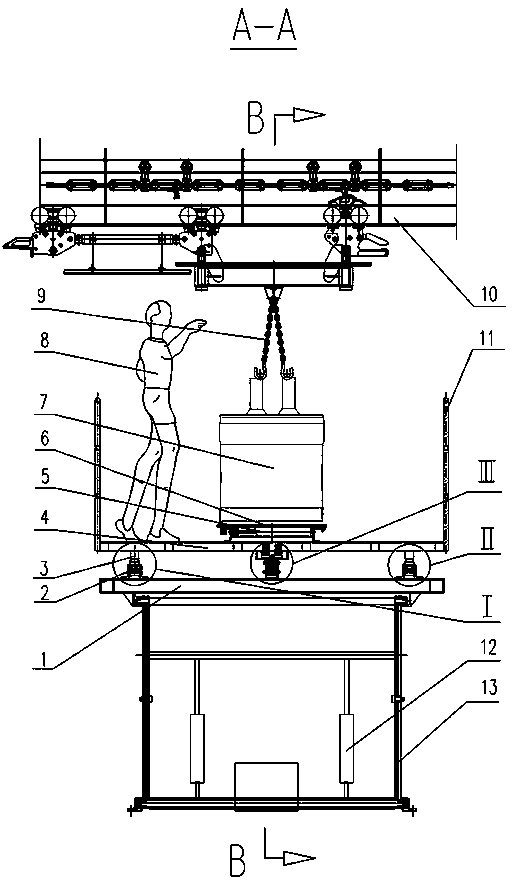

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] The workpiece 7 with large size, heavy weight and irregular shape given in the accompanying drawings of the specification of the present invention is an example of a bucket in construction machinery.

[0033] The present invention is composed of three parts: a hydraulic lifting device, a horizontal travel device and an accompanying posture correction device.

[0034] The hydraulic lifting device includes a hydraulic lifting platform 1 , a hydraulic cylinder 12 and a connecting rod 13 . The hydraulic cylinder 12 moves the hydraulic lifting platform 1 up and down through the connecting rod 13 . The horizontal moving device and the accompanying attitude checking device are arranged on the hydraulic lifting platform 1 . See figure 1 .

[0035] The horizontal moving device includes a large plate-type horizontal moving platform 4, a moving slide rail 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com