Vibration absorber bushing limiting system

A shock absorber and bushing technology, which is applied in the field of auto parts, can solve problems affecting riding comfort and suspension abnormal noise, and achieve the effects of eliminating suspension abnormal noise, improving riding comfort, and improving the riding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

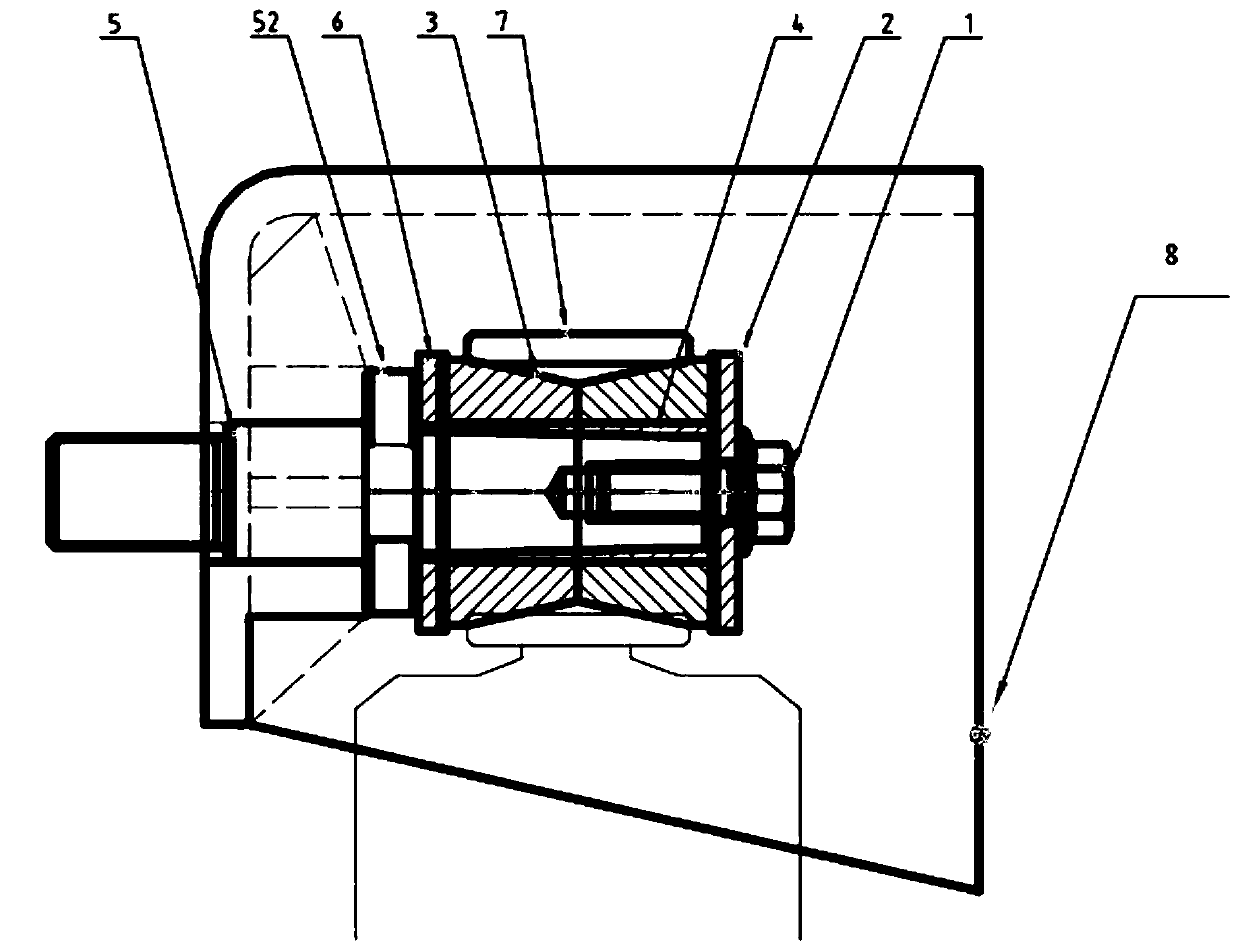

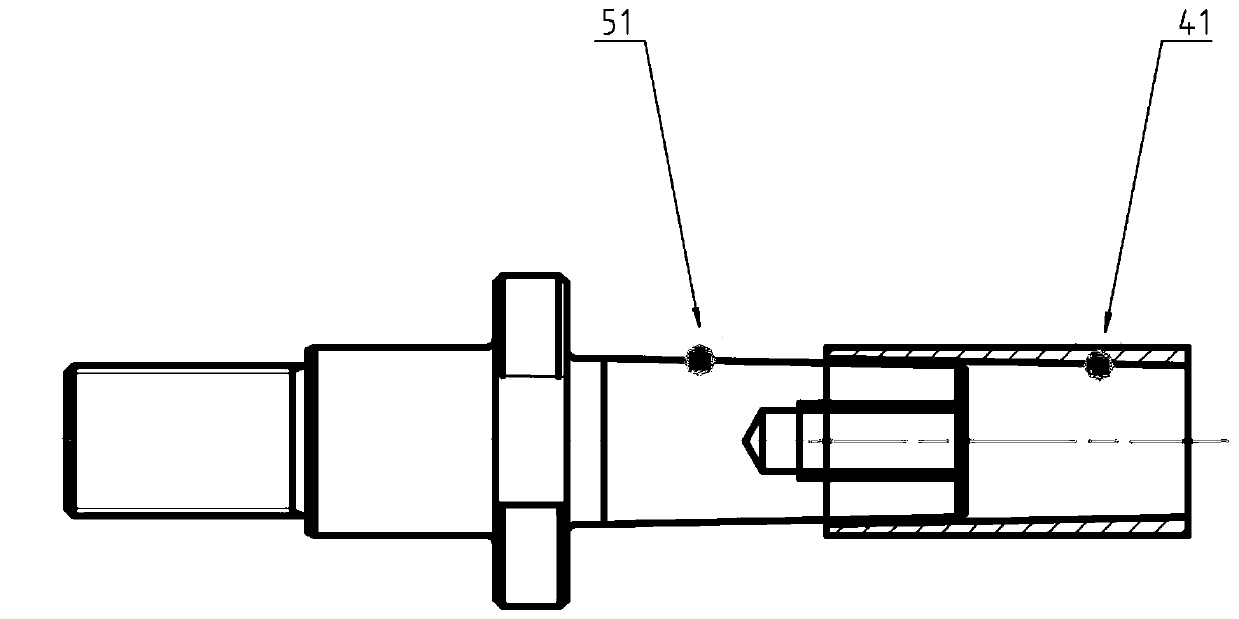

[0012] The shock absorber bush limit system of the present invention consists of a bolt (1), a first gasket (2), a shock absorber bush (3), a bush inner tube (4), a shock absorber pin (5), The second gasket (6), the shock absorber ring (7) and the shock absorber bracket 8 consist of the inner surface (41) of the bush inner tube (4) and the outer surface (51) of the shock absorber pin (5). The taper fits, the shock absorber bushing (3) is set on the bushing inner tube (4), and the first gasket (2) and the second gasket (6) are respectively placed on the shock absorber bushing (3) At both ends, the bolt (1) and the shock absorber pin (5) are connected by internal threads, the shock absorber bushing (3) is made of natural rubber and fit together with the shock absorber ring (7), and the shock absorber pin 5 and one end is placed on the shock absorber bracket 8.

[0013]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com