LED lamp and power supply control module thereof

A technology for LED lamps and power supply control, applied in the field of LED lamps, can solve the problems of poor circuit safety, unfavorable installation and maintenance, inability to achieve effective isolation of power supply, etc., to achieve the effect of ensuring safety and avoiding the danger of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the application and the features in the embodiments can be combined with each other .

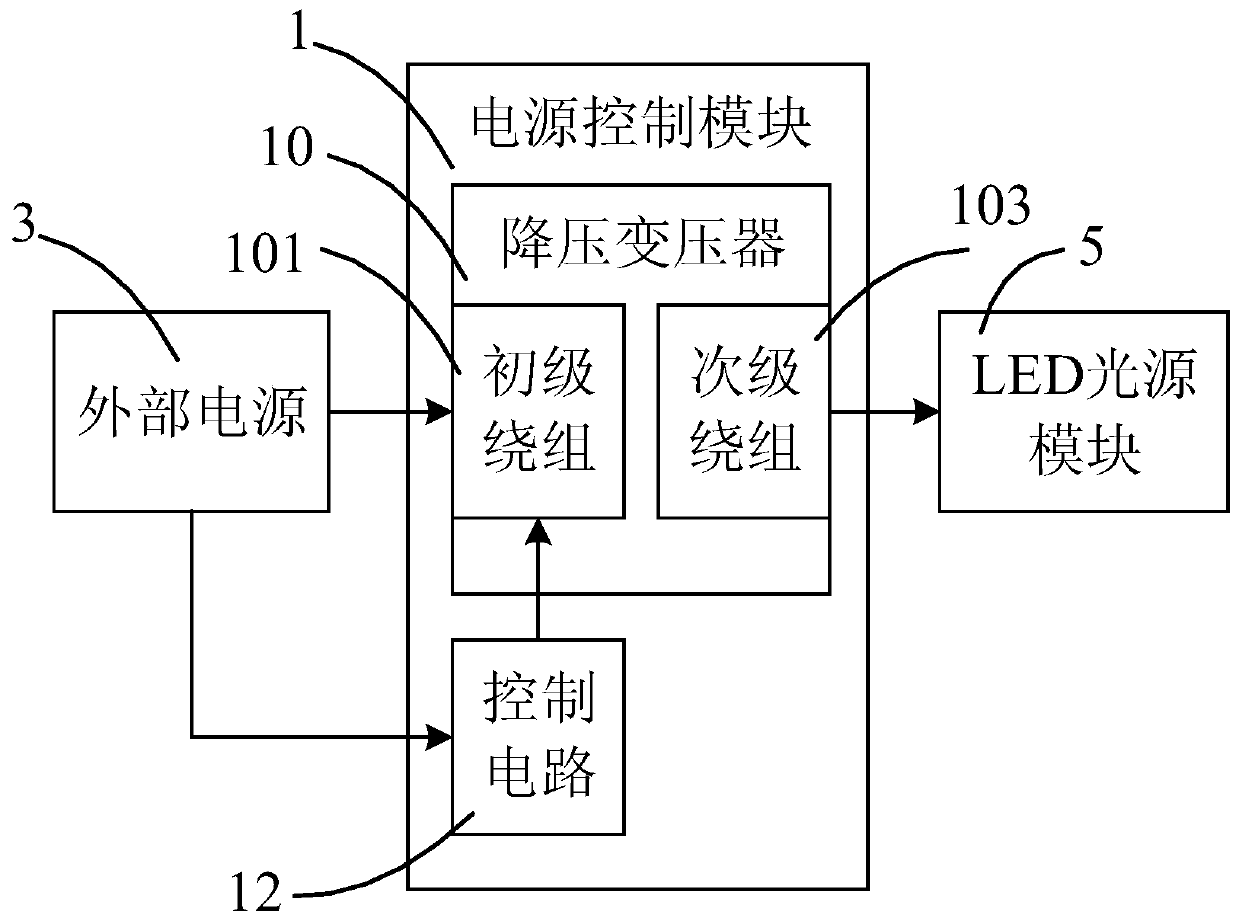

[0030] Such as figure 1 As shown, the embodiment of the present invention provides a power control module 1 of an LED lamp, which is connected between the external power supply 3 and the LED light source module 5. The power control module 1 includes:

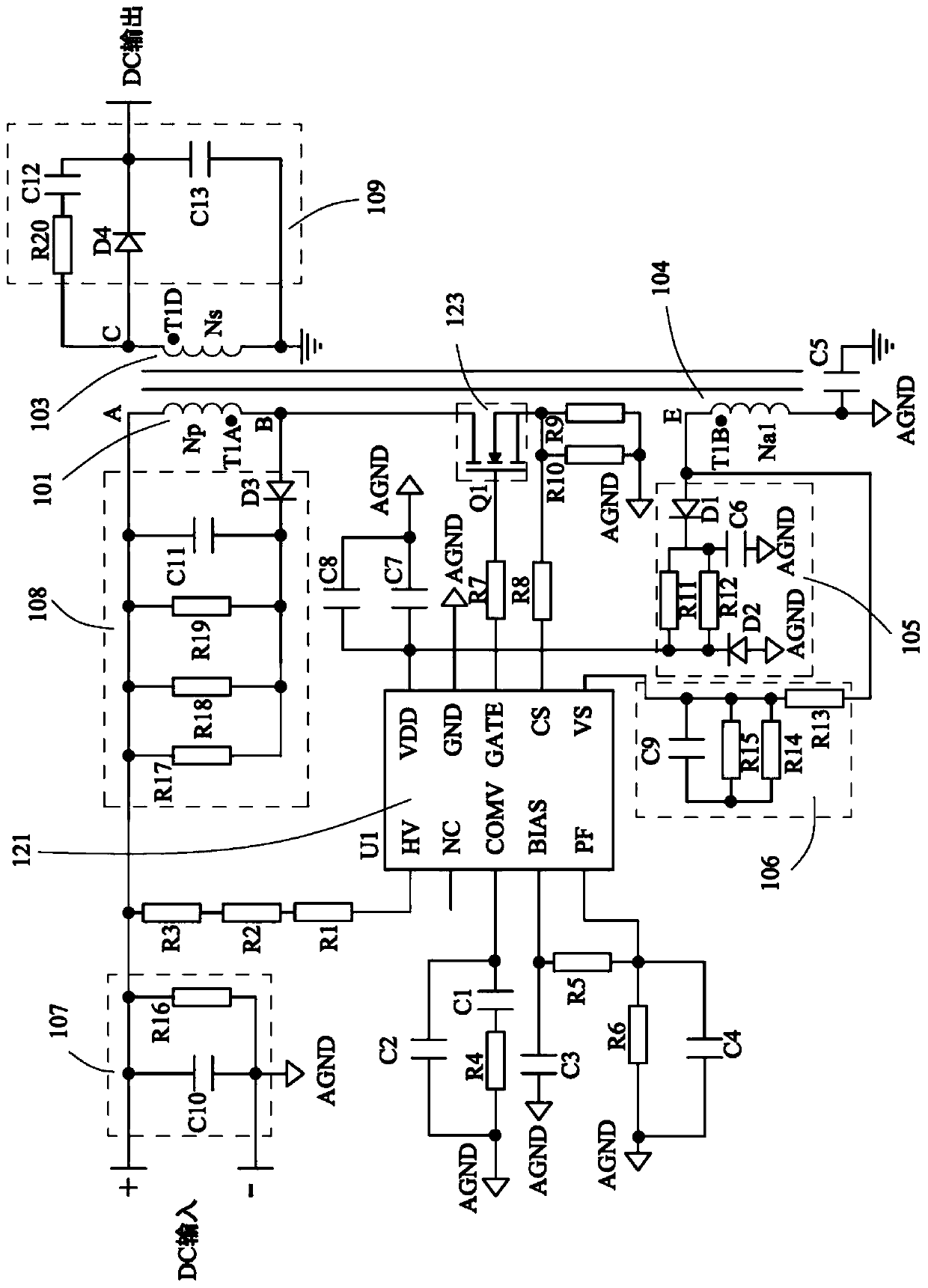

[0031] A step-down transformer 10, the primary winding 101 and the secondary winding 103 of the step-down transformer 10 are respectively connected to the external power supply 3 and the LED light source module 5, for converting the high-voltage DC voltage output by the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com