Automatic adhesive tape pasting equipment

An automatic technology for sticking tape, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of different sticking quality and low efficiency, and achieve the effect of reasonable design, avoiding manual input and high sticking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

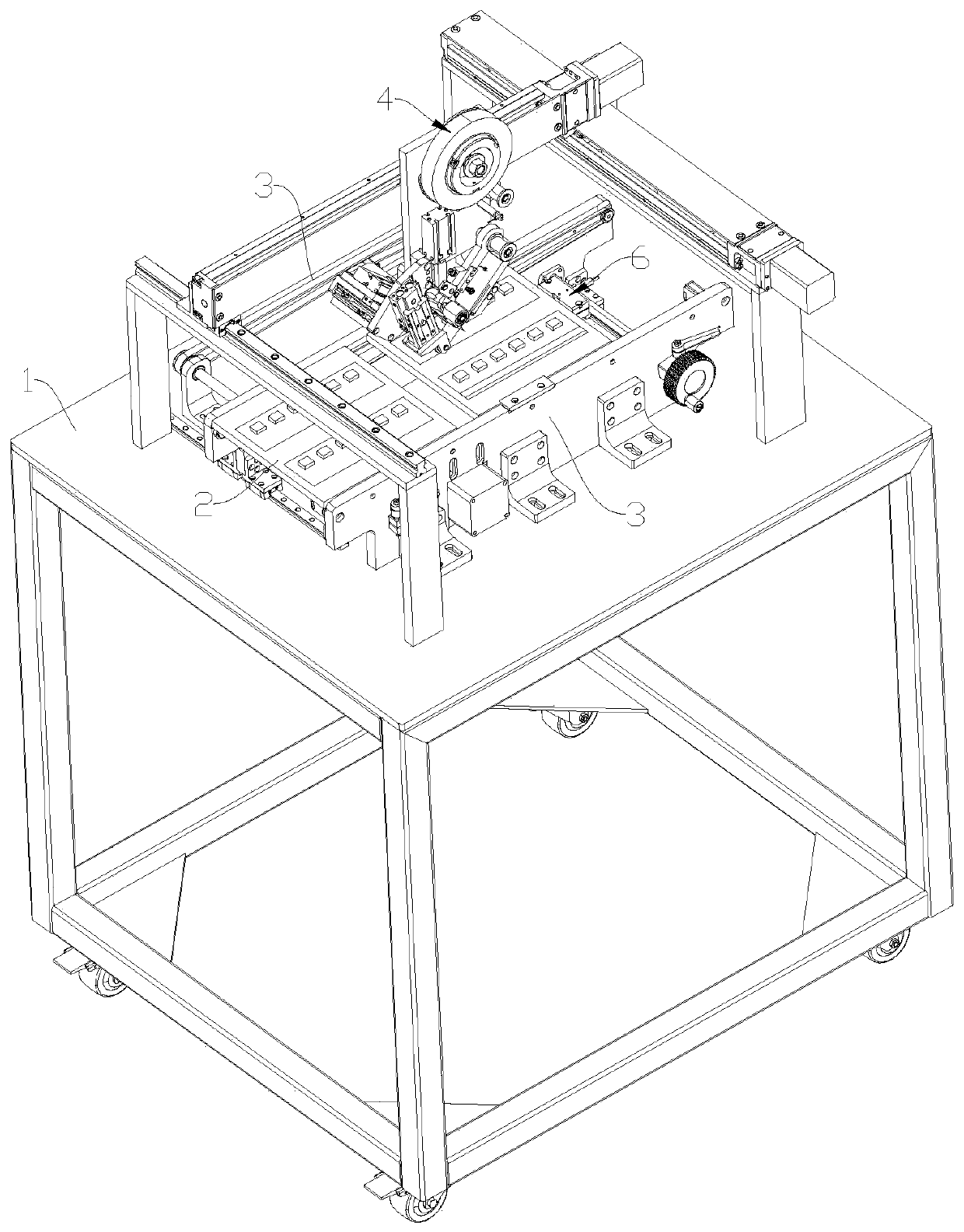

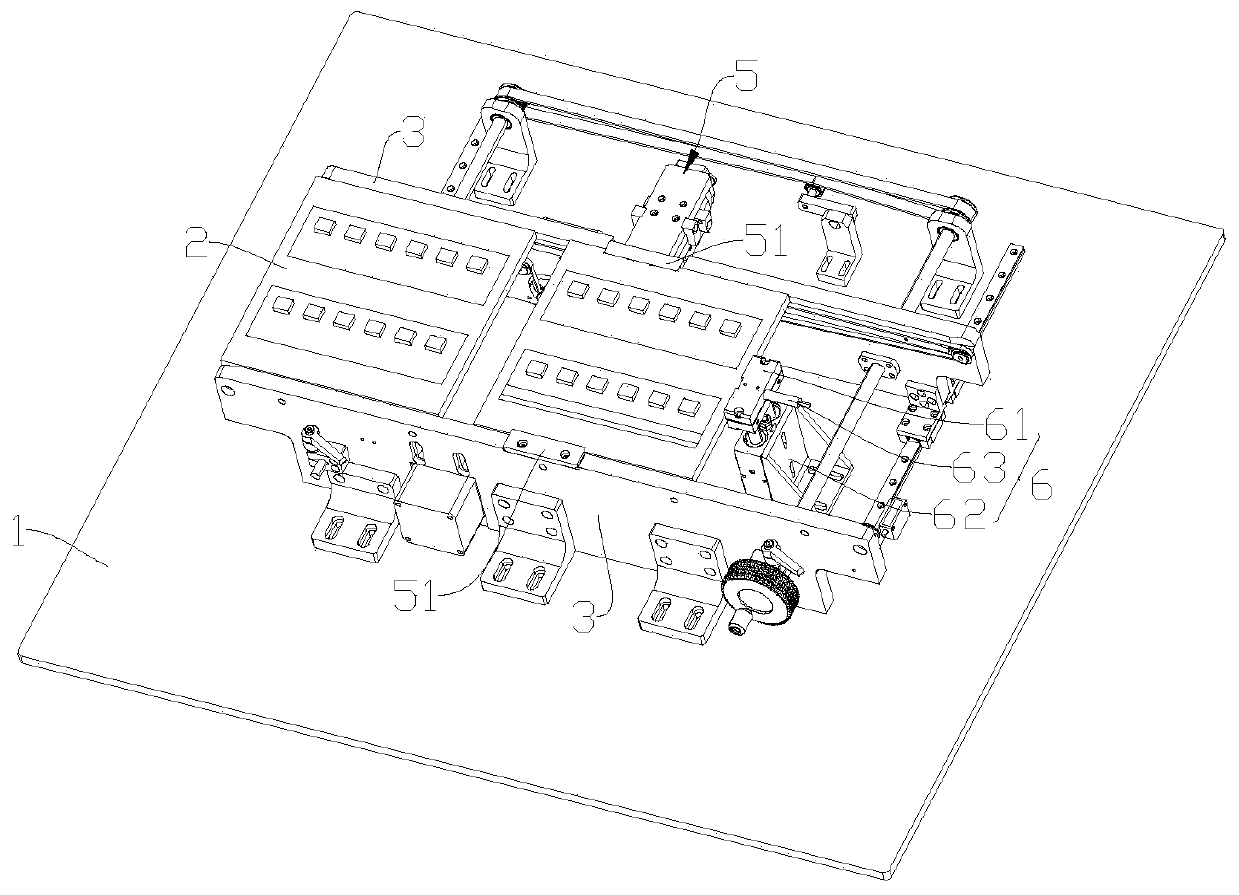

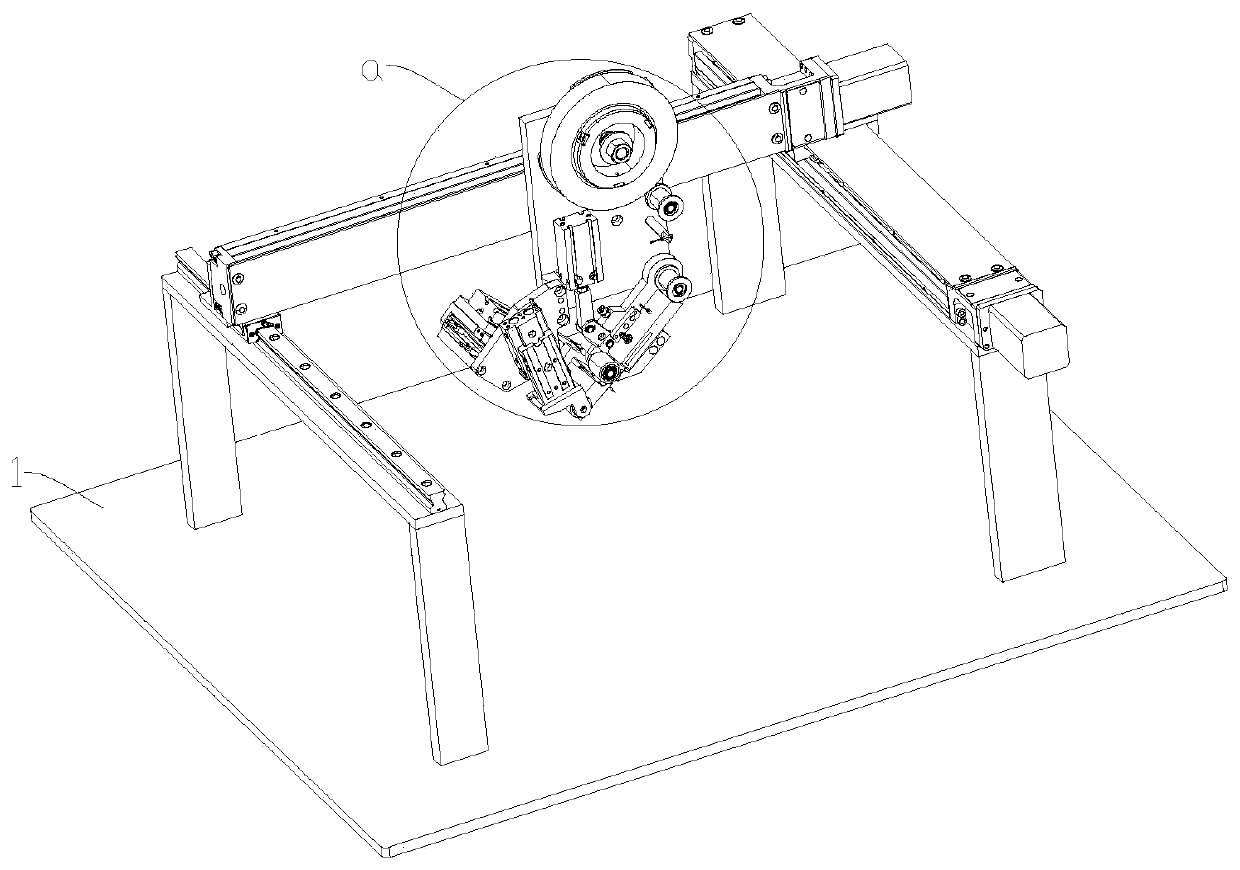

[0044] Please refer to figure 1, the present embodiment provides an automatic tape sticking device, which is used to glue the pins of semi-finished chips, including a frame 1, a clamp 2 for carrying semi-finished chips, a conveying mechanism 3 for intermittently transporting the clamp 2, and Gluing mechanism 4 for gluing the pin pins of chip semi-finished products; the conveying mechanism 3 is installed on the frame 1 parallel to each other, and the gluing mechanism 4 is connected to the frame 1 and is located on the conveying mechanism, which can move along the conveying direction of the conveying mechanism 3 3 above.

[0045] In actual production, different chip semi-finished products have different sizes, therefore, the jig 2 used to carry it is also of different specifications, and in this embodiment, in order to make this device suitable for transporting jigs 2 of more specifications, the conveying mechanism 3 It includes a pair of pulley conveyors with the same speed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com