Dynamic load indentation testing method for metal materials

A technology of metal materials and dynamic loading, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, testing material hardness, etc., can solve the problems of not being able to test other mechanics, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

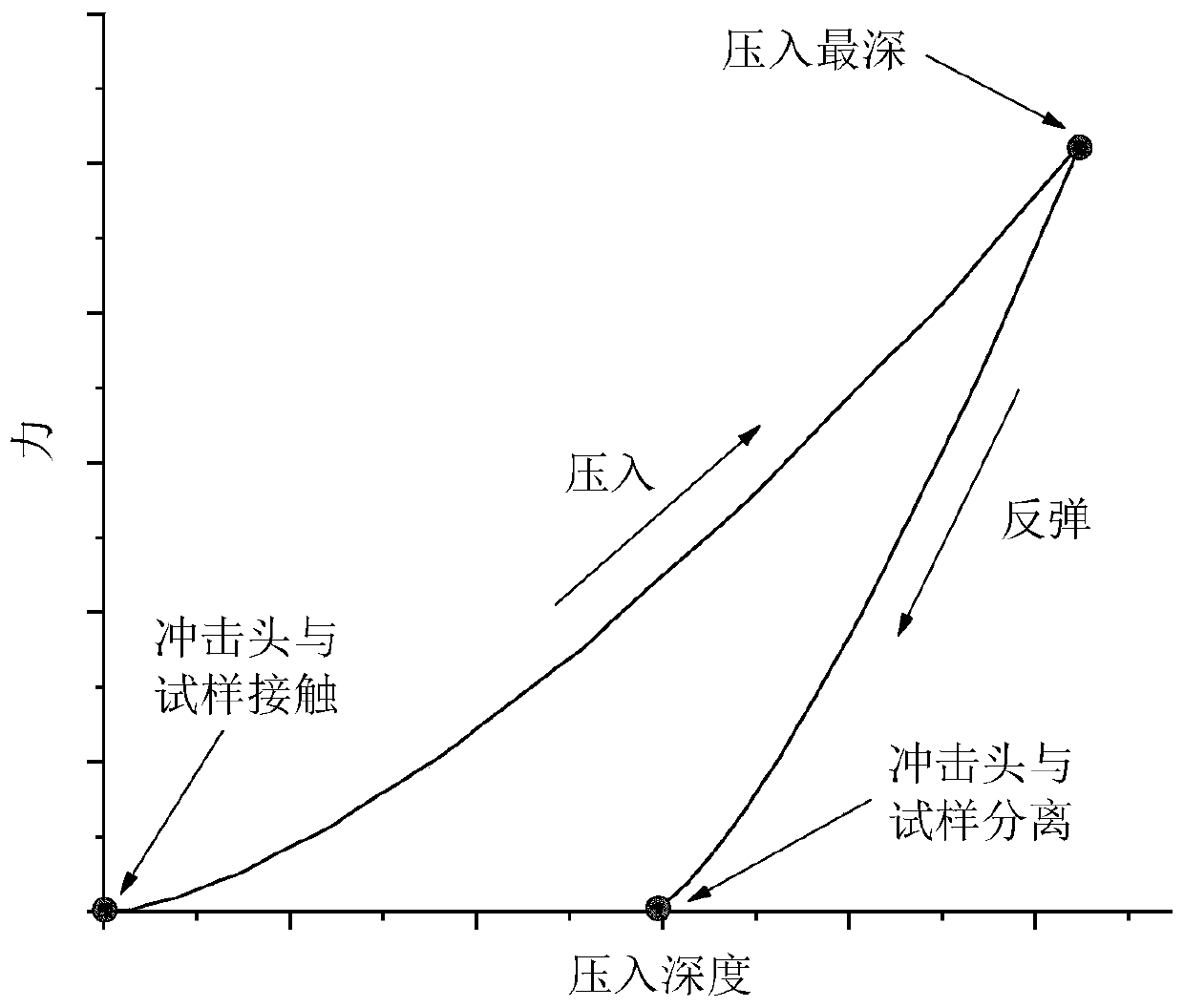

[0049] like figure 1 , a dynamic load indentation test method for metal materials, comprising the steps of:

[0050] (1) Utilize the impact pressure head mechanism 2 that is provided with the acceleration sensor 3 inside, the impact pressure head mechanism 2 lower end is provided with a spherical cemented carbide 4, vertically impacts the surface of the metal material 1 to be measured, and the impact process, the acceleration sensor 3 records the acceleration- time curve, a buffer spring 5 can also be set between the acceleration sensor 3 and the spherical cemented carbide 4 as required, when no spring is provided, the duration of the impact process is the shortest; when a spring is provided, the smaller the spring stiffness, the shorter the duration of the impact process long;

[0051] (2) Convert the obtained acceleration-time curve into the impact force-indentation depth curve, such as figure 2 shown;

[0052] (3) Repeat steps (1) and (2) to perform multiple dynamic ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com