Compatibility evaluation method and system for material loaded based on constant displacement and high-pressure hydrogen

A technology of high-pressure hydrogen gas and evaluation method, which is applied in the direction of using stable tension/pressure to test the strength of materials, analyze materials, strength characteristics, etc. Stability, effect of reducing the risk of hydrogen leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

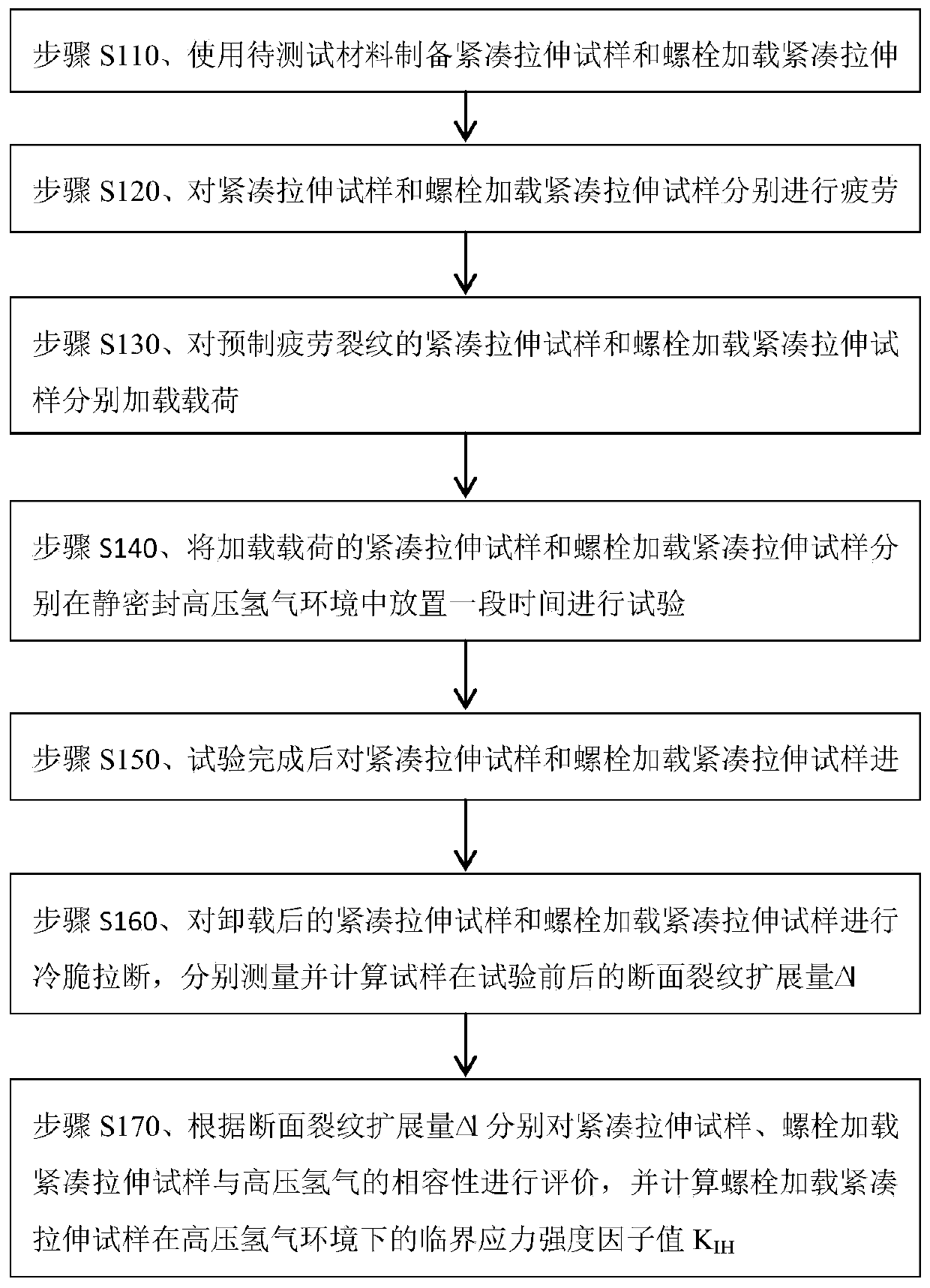

[0059] Such as figure 1 As shown, this embodiment proposes a method for evaluating the compatibility of materials with high-pressure hydrogen gas based on constant displacement loading. The method includes the following steps:

[0060] Step S110 , using the material to be tested to prepare a compact tensile sample and a bolt-loaded compact tensile sample.

[0061] Sample preparation and dimension measurement:

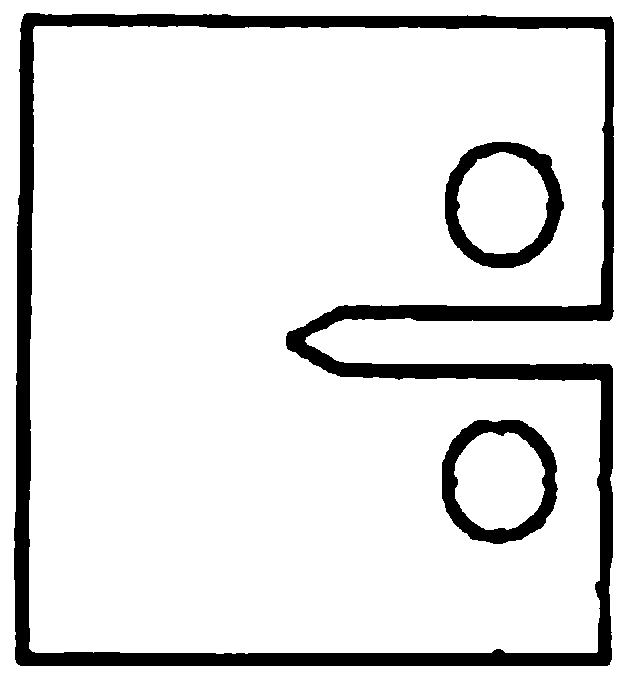

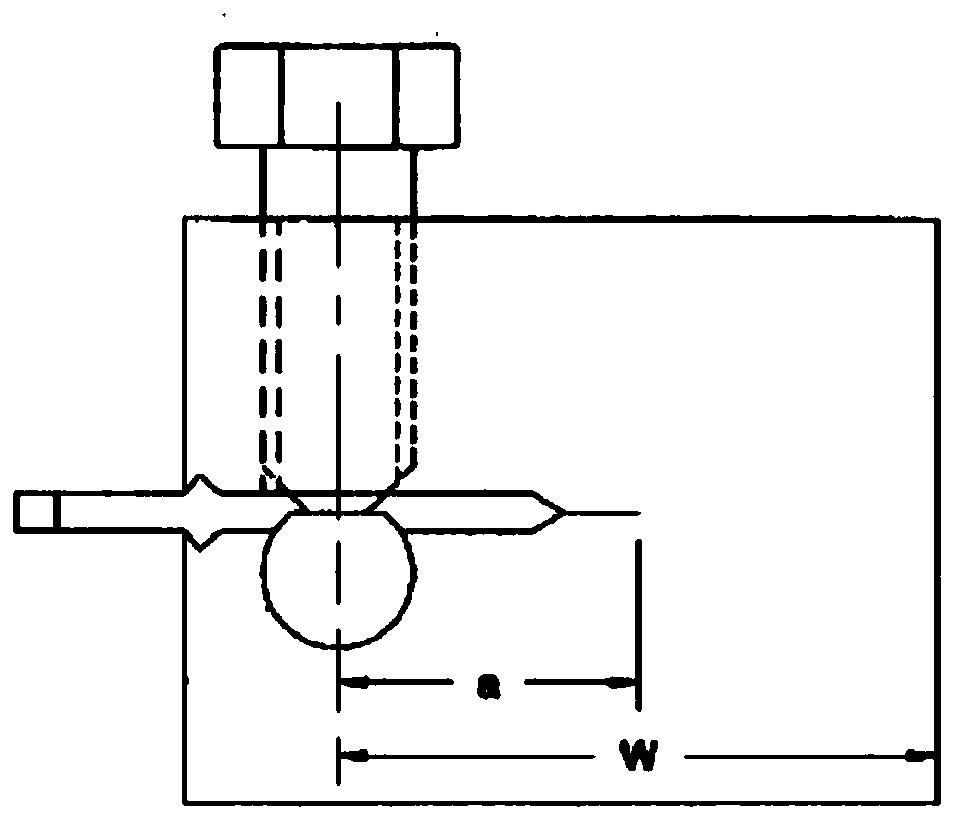

[0062] The test adopts compact tensile specimen (abbreviation: CT specimen, such as figure 2 shown) and modified bolt-loaded compact tensile specimens (referred to as: WOL specimens, such as image 3 As shown), the WOL sample can also be called the bolt-loaded CT sample. The difference between it and the CT sample is that the CT sample is loaded with a wedge block, while the WOL sample is loaded with a bolt. Before the test, the surface of the sample was degreased and derusted. The thickness B of the sample is a key parameter that needs to be determined. The select...

Embodiment 2

[0131] Corresponding to the above-mentioned embodiment 1, such as Figure 4 As shown, this embodiment proposes a material and high-pressure hydrogen compatibility test system based on constant displacement loading, which includes:

[0132] The sample preparation module 210 is used to prepare a compact tensile sample and a bolt-loaded compact tensile sample using the material to be tested.

[0133] The crack prefabrication module 220 is configured to perform fatigue crack prefabrication on the compact tensile specimen and the bolt-loaded compact tensile specimen respectively.

[0134] The loading module 230 is configured to load the compact tension sample with prefabricated fatigue cracks and the bolt loaded compact tension sample respectively.

[0135] The test module 240 is configured to place the loaded compact tensile sample and the bolt-loaded compact tensile sample respectively in a statically sealed high-pressure hydrogen environment for a period of time for testing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com